Warehouse patrolling unmanned aerial vehicle system and patrolling method thereof

A drone and warehouse technology, applied in the field of warehouse management, can solve the problems of low-risk, undisclosed warehouse line inspection, etc., and achieve the effect of reducing the waste of electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

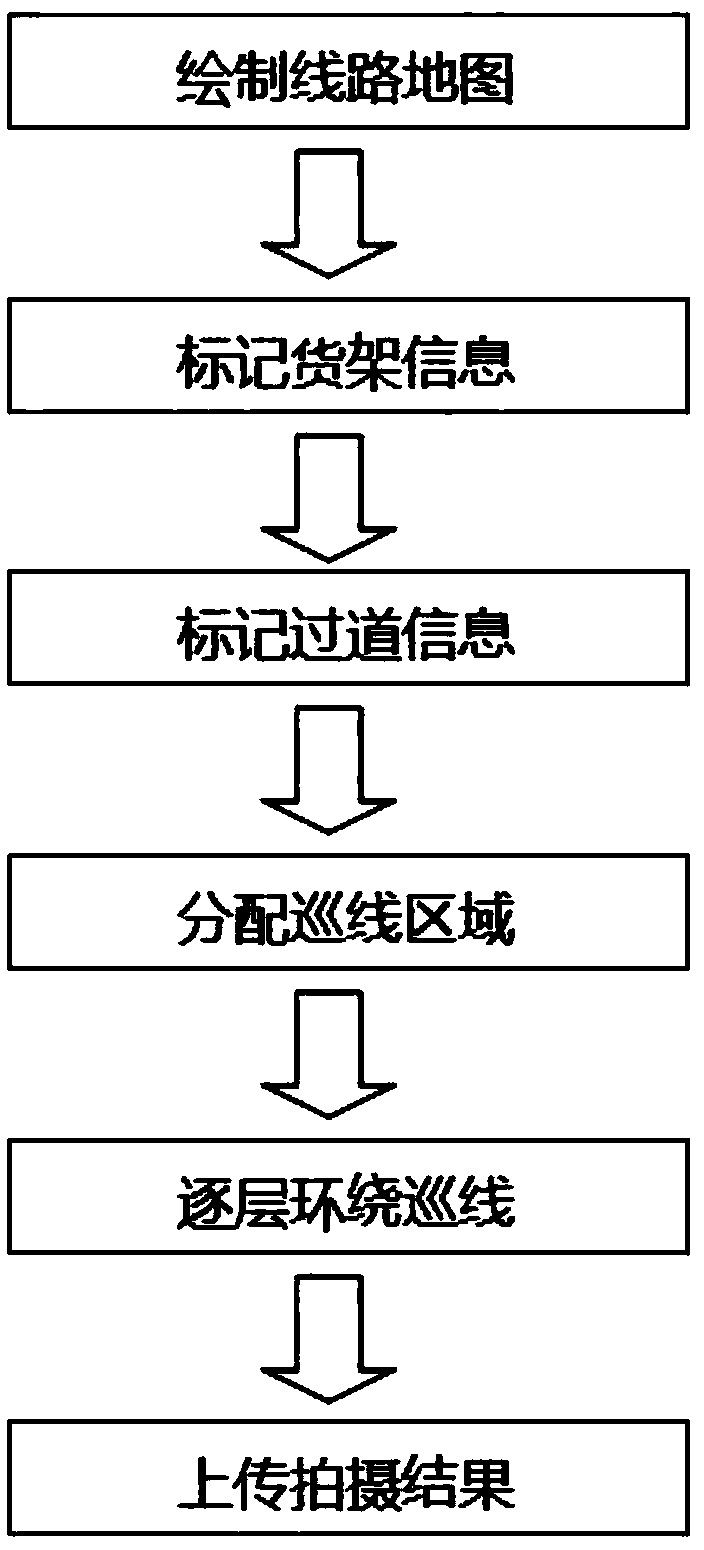

[0023] like figure 1 As shown, a warehouse patrol UAV system includes an infrared obstacle avoidance module, a shooting module, a charging module, a camera platform, an altimeter, a stabilizer, a server, a flight control module and a processor, and the infrared obstacle avoidance module: uses When patrolling the line, the road is automatically detected to realize automatic steering and avoidance; the shooting module: set on the camera platform for taking videos or photos of goods; the camera platform: drives the camera module to rotate at multiple angles; The server: used to command and control the operation of the UAV in the background, and send corresponding instructions to the UAV; the altimeter: used to measure the flying height of the UAV; the stabilizer: used to ensure that the UAV can be safely Stable flight; the flight control module: realize the flight control of the drone, including forward, backward, lifting and steering; the processor: control the operation of the ...

Embodiment 2

[0035] like figure 1 As shown, a warehouse patrol UAV system includes an infrared obstacle avoidance module, a shooting module, a charging module, a camera platform, an altimeter, a stabilizer, a server, a flight control module and a processor, and the infrared obstacle avoidance module: uses When patrolling the line, the road is automatically detected to realize automatic steering and avoidance; the shooting module: set on the camera platform for taking videos or photos of goods; the camera platform: drives the camera module to rotate at multiple angles; The server: used to command and control the operation of the UAV in the background, and send corresponding instructions to the UAV; the altimeter: used to measure the flying height of the UAV; the stabilizer: used to ensure that the UAV can be safely Stable flight; the flight control module: realize the flight control of the drone, including forward, backward, lifting and steering; the processor: control the operation of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com