Filtering apparatus

A filter device and main housing technology, applied in the field of air purification, can solve the problems of high energy consumption, large volume of water removal device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further illustrate the principle and structure of the present invention, preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

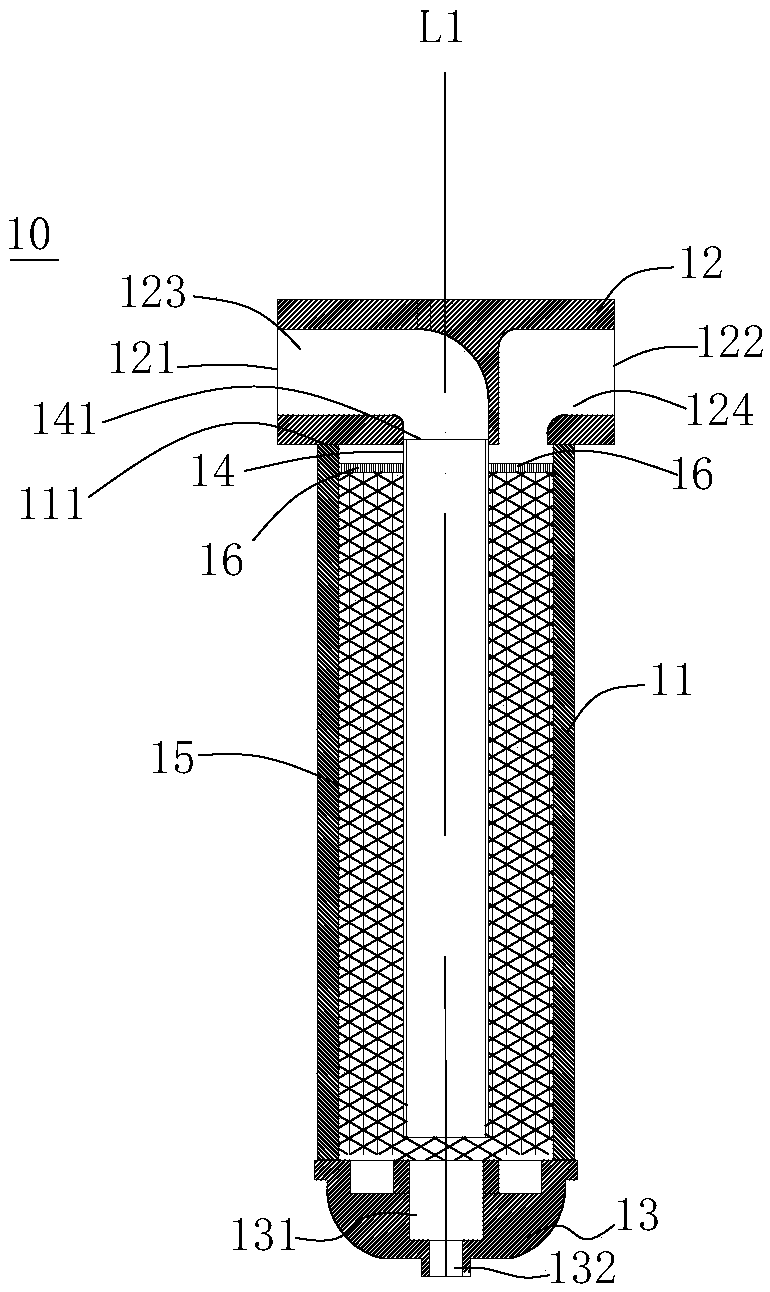

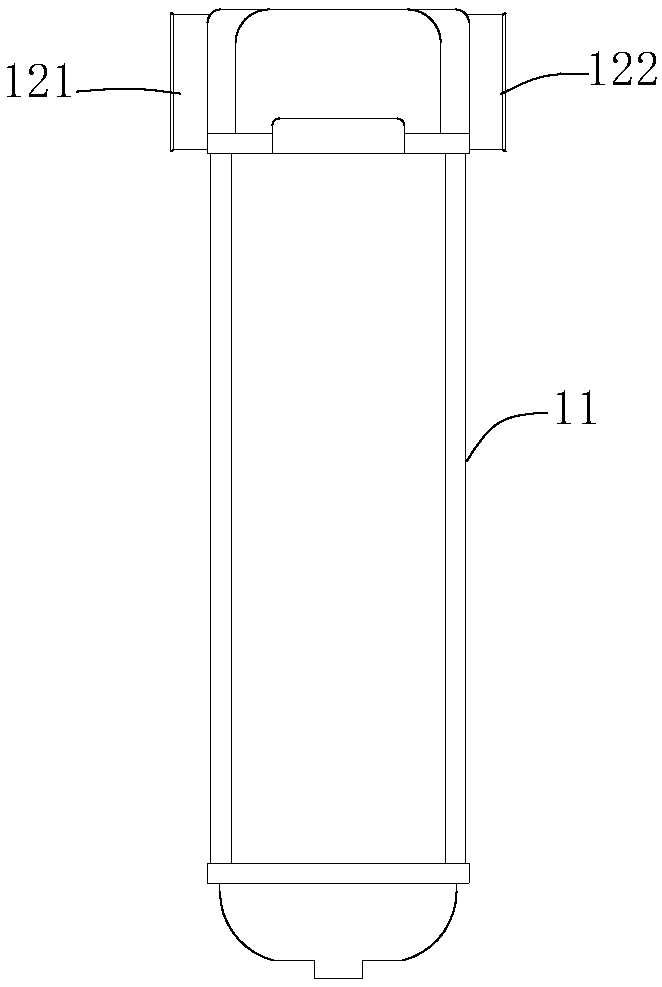

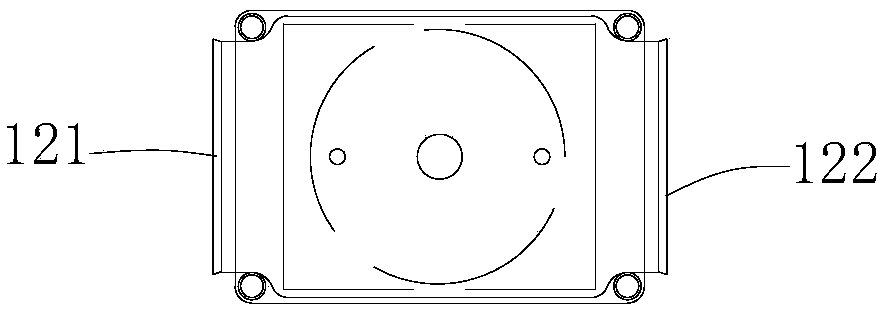

[0033] Such as Figure 1 to Figure 3 as shown, figure 1 It is a longitudinal sectional view of the filter device of the present invention in the first embodiment, figure 2 for figure 1 stereogram of image 3 for figure 2 is a schematic top view, the filtering device 10 includes a main housing 11, an upper cover 12 and a lower cover 13 closely connected with the upper end and lower end of the main housing 11 respectively, a flow guide tube 14 arranged in the inner cavity of the main housing 11 and The wire mesh 15 is located in the inner cavity of the main casing 11 and filled in the outer periphery of the draft tube 14 .

[0034] The main casing 11 is tubular or cylindrical, and it may be an aluminum alloy tube made of aluminum alloy. It can be understood...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com