Automatic bearing cleaning machine

A technology for automatic cleaning machines and bearings, which is applied to dryers, cleaning methods and tools, and cleaning methods using liquids, etc., which can solve the problems of poor cleaning of bearings, waiting for shutdown, and low processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

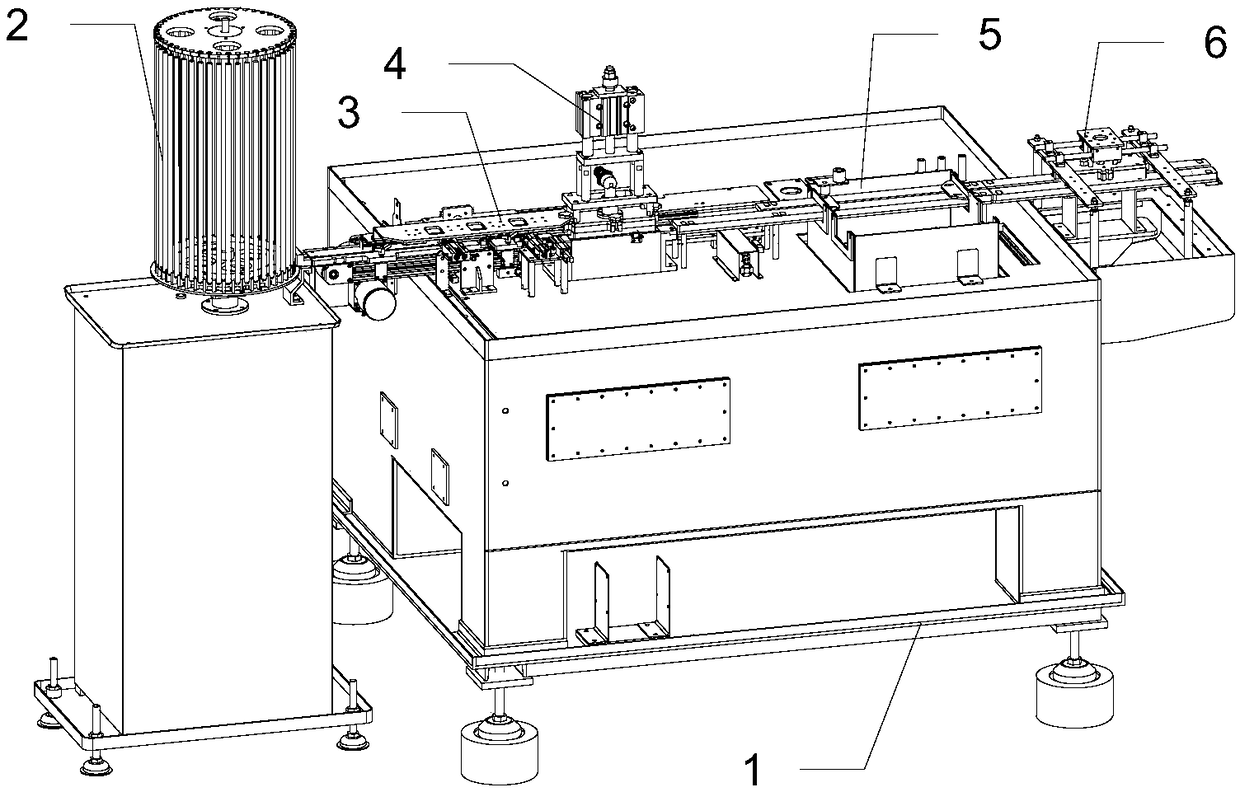

[0025] Such as Figure 1-Figure 12 The shown automatic bearing cleaning machine includes a frame 1 and a feeding system 2 on it, a material pushing system 3 , a bearing cleaning system 4 , an ultrasonic cleaner 5 , and a drying system 6 .

[0026] The feeding system 2 is connected with the pushing system 3, the positions of the bearing cleaning system 4, the ultrasonic cleaner 5 and the drying system 6 correspond to the pushing system 3, and the pushing system 3 sequentially drives the bearing through the bearing cleaning system 4, the ultrasonic cleaner 5 and the Blow dry the bearing movement on the system 6. The bearing cleaning system 4 completes the high-pressure cleaning of the bearings; the ultrasonic cleaner 5 completes the ultrasonic cleaning of the bearings; the drying system 6 dries the liquid on the bearings.

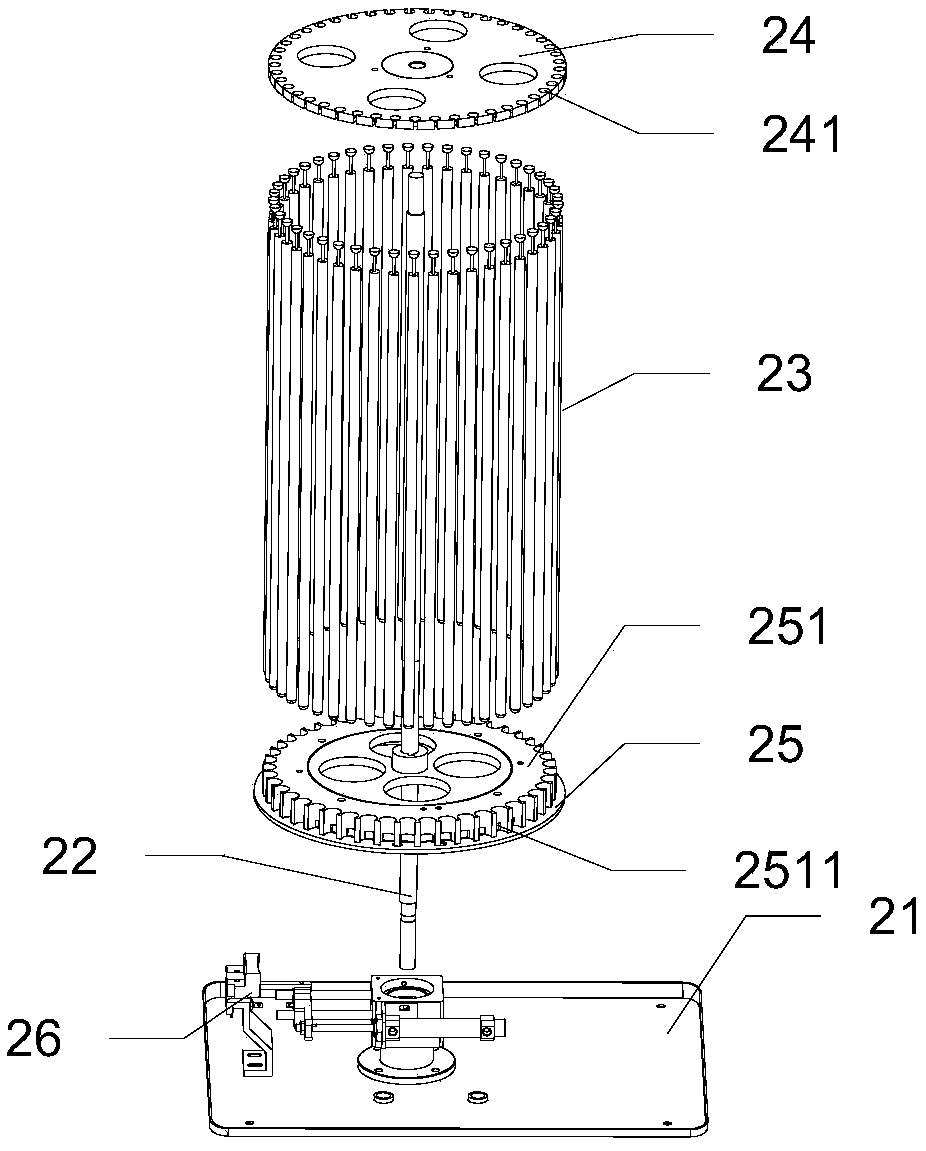

[0027] The feeding system 2 includes a placement disc 21, a rotating shaft 22, a sleeve rod 23, an upper rotating disc 24, a lower rotating disc 25, a push ...

Embodiment 2

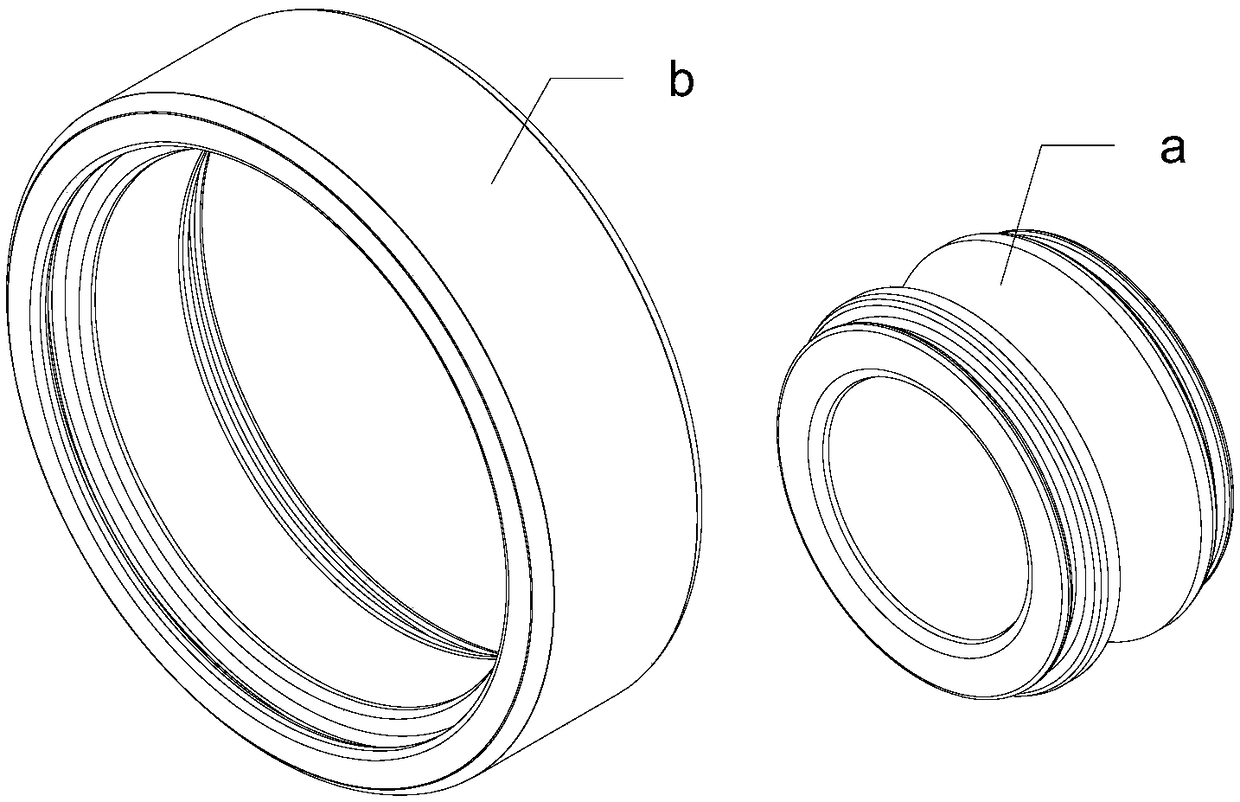

[0046] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 12 , Figure 13 , Figure 14 and Figure 15 The shown automatic bearing cleaning machine includes a frame 1 and a feeding system 2 on it, a material pushing system 3 , an outer wheel cleaning system 9 , an ultrasonic cleaner 5 , and a drying system 6 .

[0047] The difference between this embodiment and Embodiment 1 is that the bearing cleaning system 4 is different, and other structures are the same as Embodiment 1. The bearing cleaning machine of this embodiment is more suitable for cleaning the outer wheel b.

[0048] The bearing cleaning system 4 includes a third lifting cylinder 91 , an outer wheel cleaning device 92 and an outer wheel cleaning seat 93 . The third lifting cylinder 91 is installed on the frame 1 through the cylinder base, the third lifting cylinder 91 is connected to the outer wheel cleaning device 92 through the connecting frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com