Disc-shaped tooth gear chamfering cutter for cylindrical gear tooth profile chamfering and manufacturing method

A technology of cylindrical gears and helical cylindrical gears, which is applied to gear tooth manufacturing devices, gear tooth manufacturing tools, gear teeth, etc., can solve the problems of long adjustment time, high purchase price, and high price, and achieve good chamfering effect and manufacturing Easy, even-edged results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

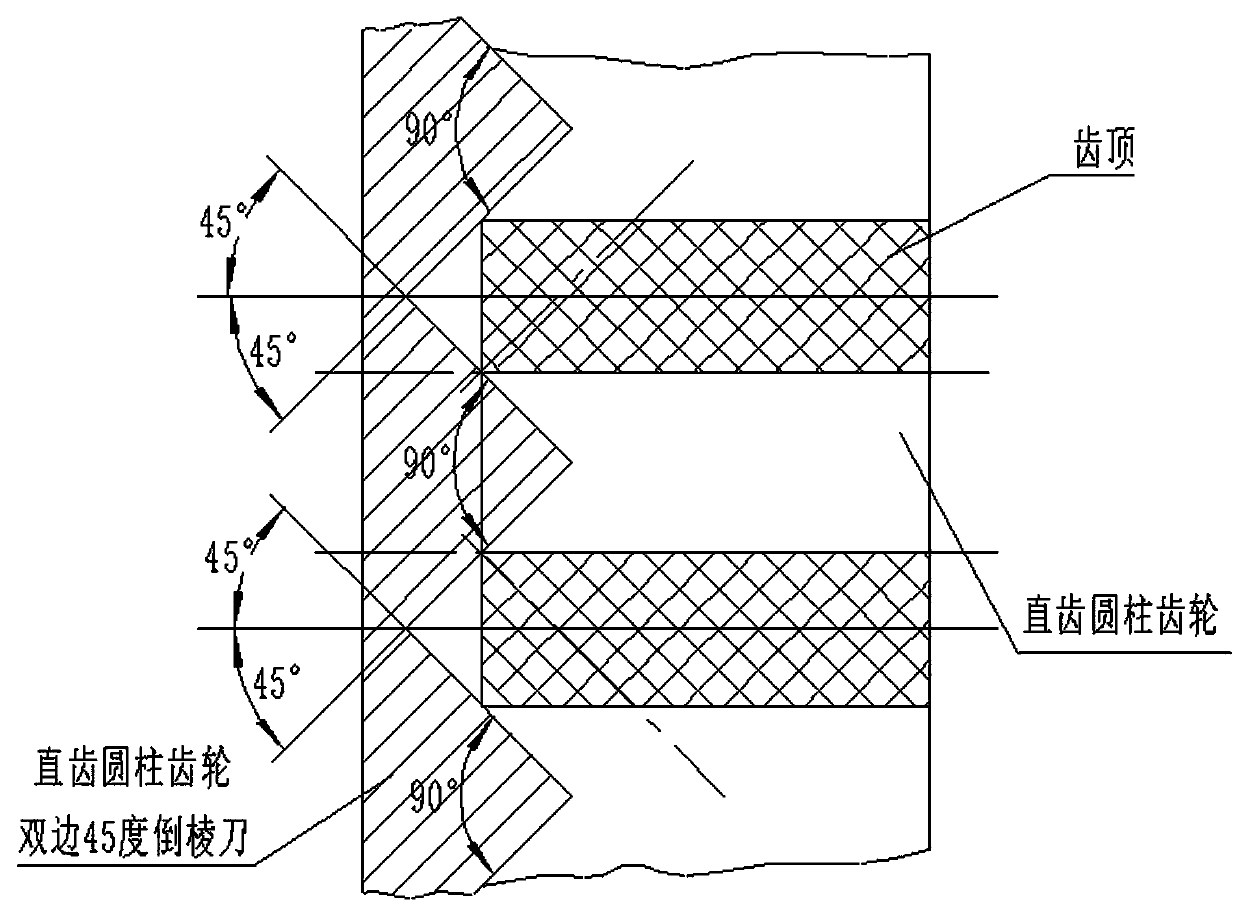

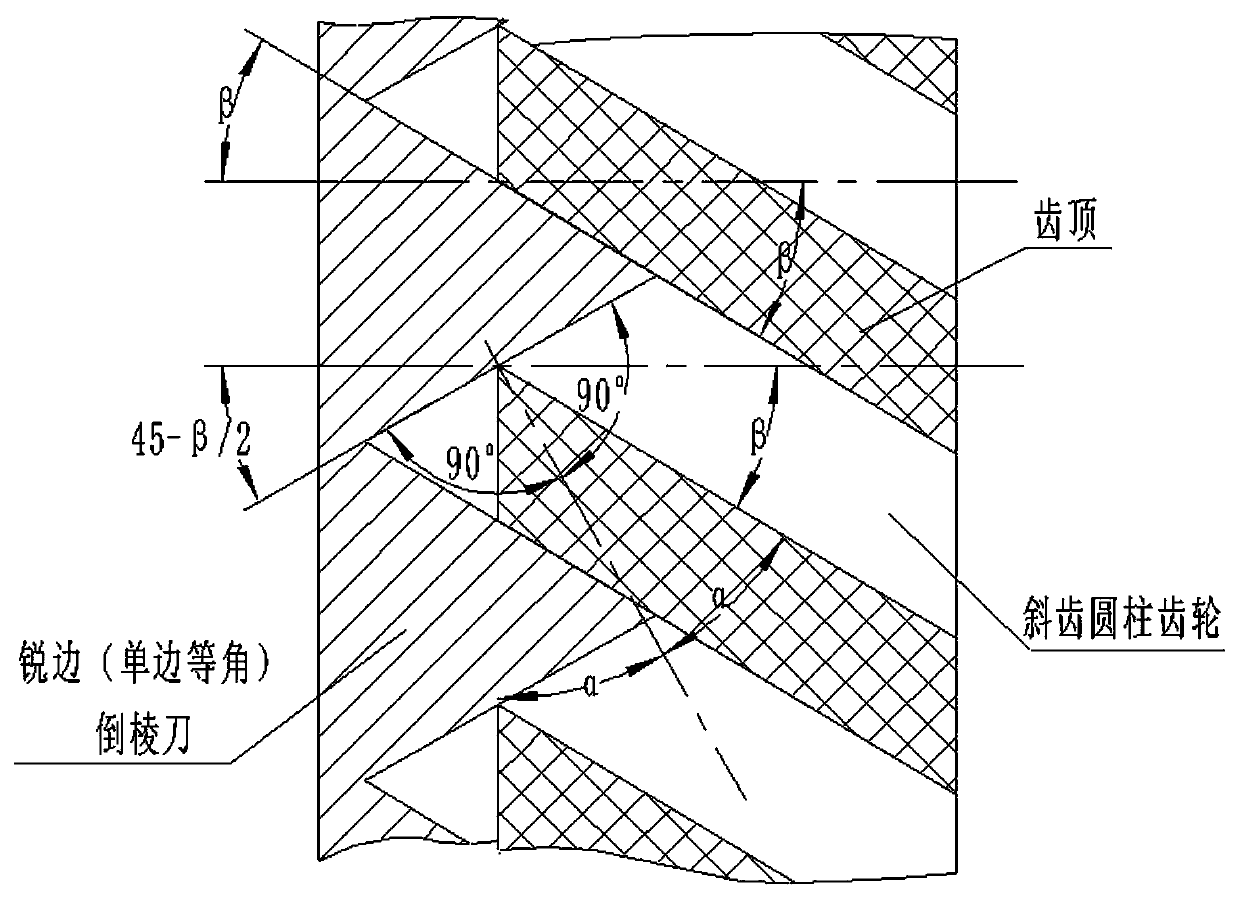

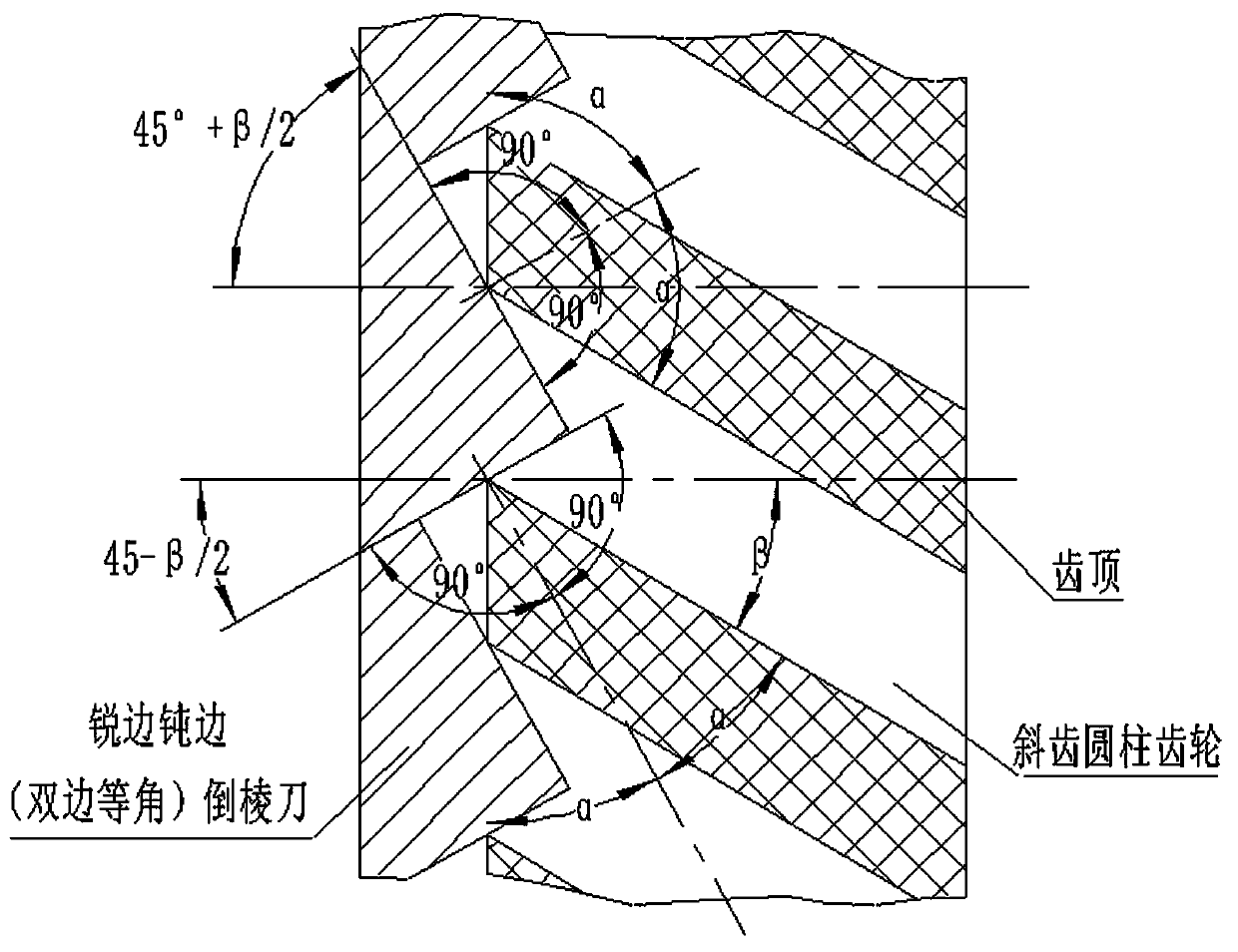

[0043] a. The disc-shaped gear chamfering cutter is composed of several V-shaped cutting surfaces (file surfaces) in the working part. The intersection line between the cutting surface and each section is theoretically formed by the involute formed by the same base circle, and the two cutting surfaces respectively resemble the tooth surfaces of left-handed and right-handed cylindrical helical gears.

[0044] b. When the disc-shaped gear chamfering cutter is cutting, several V-shaped filing surfaces are in contact with the edges of the gear tooth profile alternately. The cutting process is similar to the filing process of a file.

[0045] c. The axis of the chamfering knife is parallel to the axis of the gear being machined. During the meshing process of the tool and the gear, the edge cutting process is performed by using the relative sliding between the tooth surfaces and the axial feed pressure.

[0046] d. Regardless of whether it is chamfering the tooth profile of a spur ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com