Auxiliary fixture for automobile part detection

A technology for auxiliary fixtures and parts, applied in the direction of chucks, manipulators, manufacturing tools, etc., to achieve the effect of convenient multi-faceted detection, convenient detection, and prevention of slipping off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

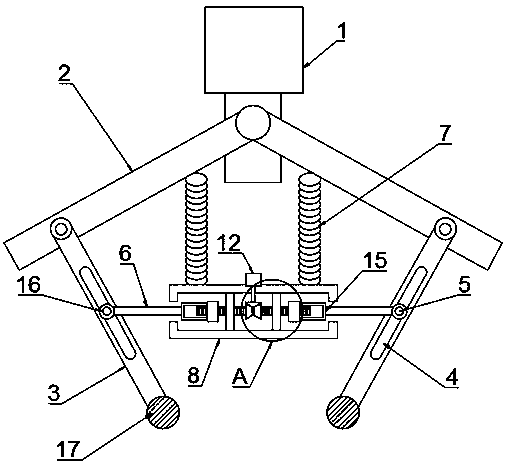

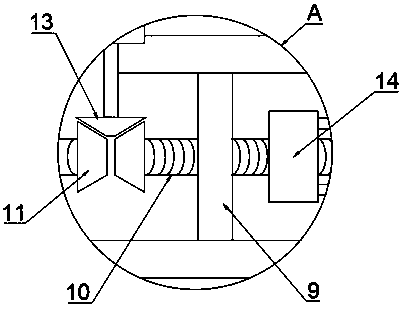

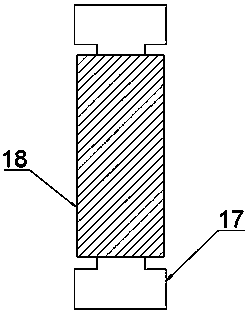

[0024] refer to Figure 1-4 , an auxiliary fixture for motor vehicle parts detection, comprising a stepping motor 1 and two fixing plates 2 fixedly connected to the driving end of the stepping motor 1, the two fixing plates 2 are driven to rotate by the rotation of the driving end of the stepping motor 1 , and then drive the clamped parts to rotate, which is convenient for multi-faceted detection. There is a predetermined angle between the two fixed plates 2, and the angle between the two fixed plates 2 is 90-135 degrees. Both are connected with splint 3 through the rotation of the shaft, and the ends of the two splints 3 away from the fixed plate 2 are fixedly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com