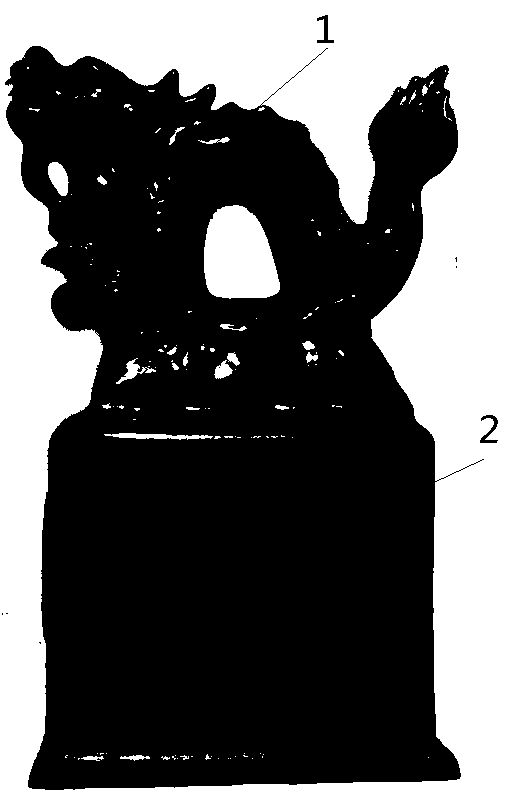

Manufacturing method of jun porcelain artware with dragon seal shape

A production method and technology for handicrafts, applied in the field of craftsmanship, can solve the problems that handicrafts cannot reflect artistic style and have no shocking force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Embodiment one, such as figure 1 , according to step 1, carve the dragon, dragon ball, and base 2 of dragon 1 into 8 models according to the design and the common method in this industry, and keep the shape of the original design of each part to meet the requirements; because the shape of each part is small and stretched , it is difficult to make molds after overall engraving, and it is easy to produce waste products;

[0010] In this example, according to step 2, the 8 models carved in step 1 are used to make 8 sets of plaster molds respectively by the method commonly used in this industry, which can simplify the difficulty of manufacturing models and molds;

[0011] In this example, step 3 uses high alumina, and adds 7% metal aluminum and 6% silicon to the high alumina, because the wall thickness of this handicraft is relatively thin, so its blank form needs to increase its refractory performance;

[0012] In step 4 of this example, the clay in step 3 is used, crushe...

Embodiment 2

[0026] Embodiment 2, the color of dragon 1 selected in step 8 in this example is furnace junjin mottled glaze, which is similar to the color of ancient bronzes. 6%, zinc oxide 5%, potassium feldspar 10%, malachite 3%, tin oxide 0.5%; including not more than 2% copper, and 20% plant ash; crush the above glaze into 400 mesh fine powder , add water and stir and filter to form a glaze slurry; other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com