Patents

Literature

33results about How to "Embody design thinking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Scheduling task publishing system and method

PendingCN111240819AEmbody decouplingEmbody design thinkingProgram initiation/switchingResource allocationComputer architectureEngineering

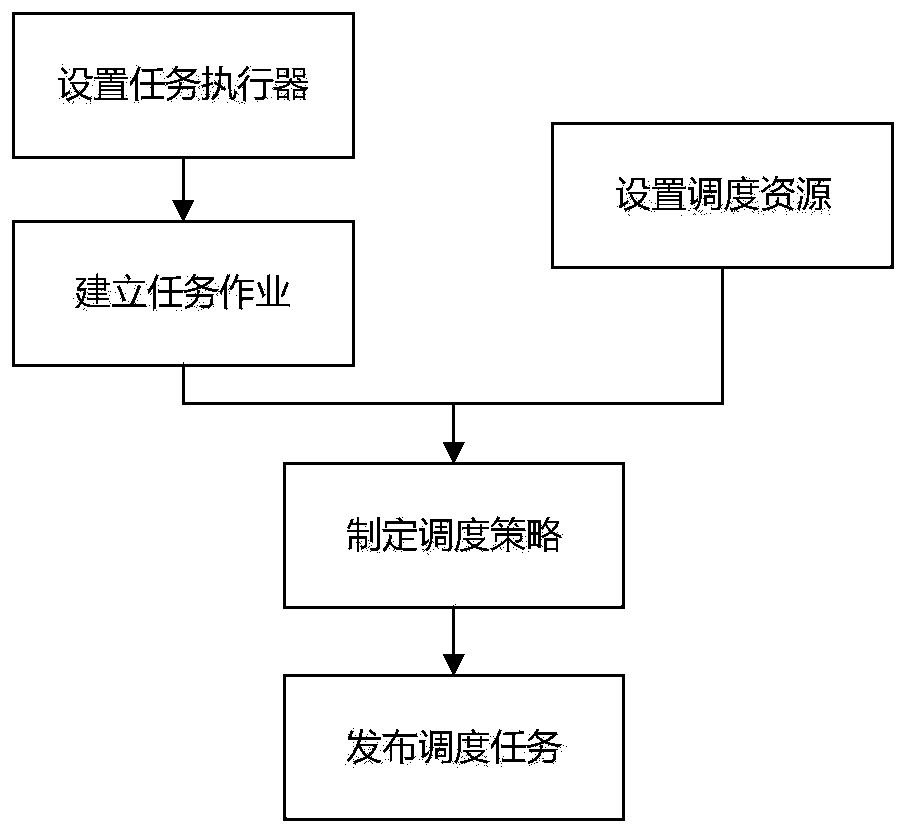

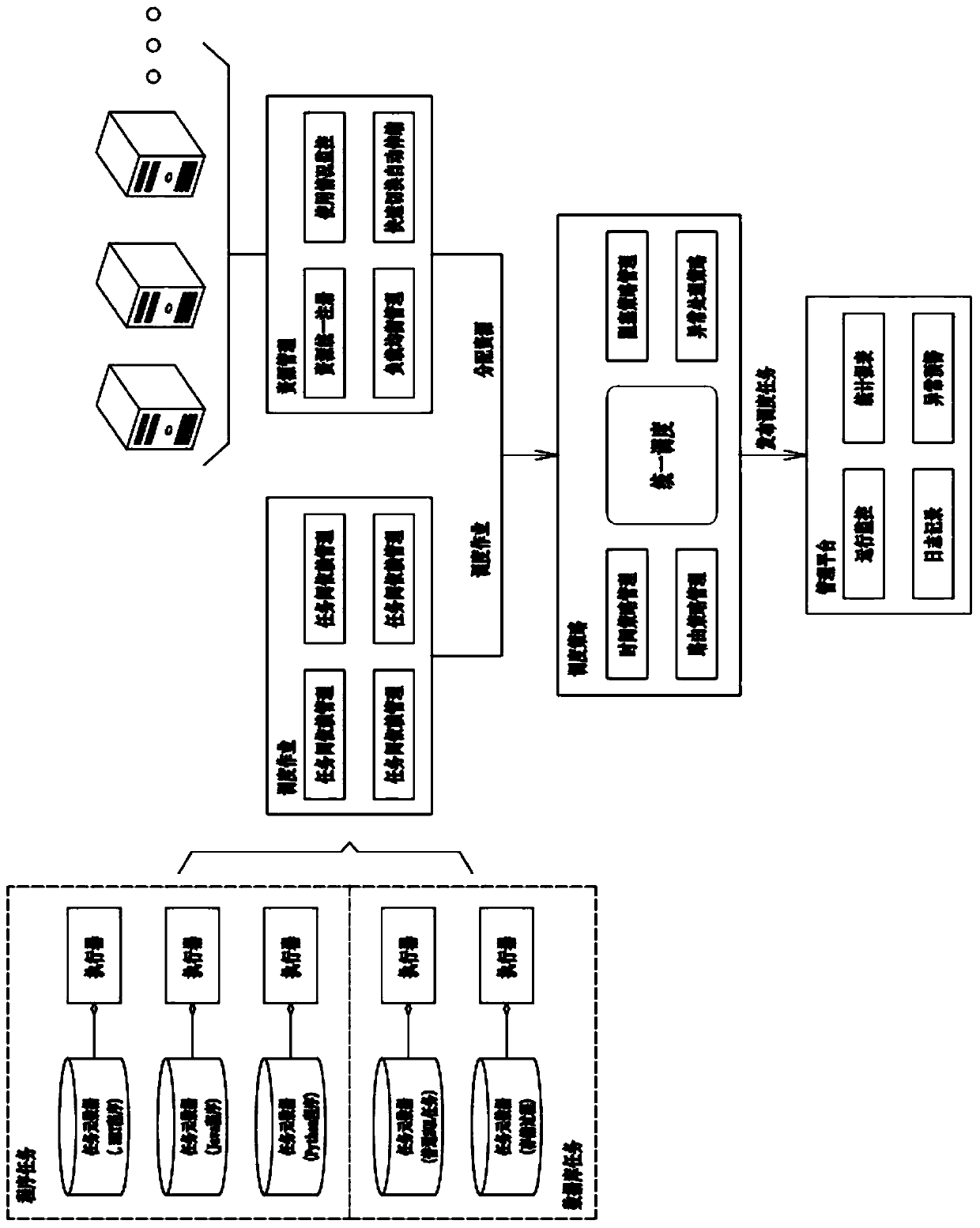

The invention discloses a scheduling task publishing system and method. The scheduling task publishing method comprises the following steps: S1, delivering a scheduling task to be published to a corresponding task executor to be responsible for scheduling execution; s2, configuring hardware scheduling resources required by operation for the scheduling task; s3, associating the scheduling tasks according to a logic relationship, and combining the scheduling tasks into scheduling jobs; s4, establishing a scheduling strategy for each scheduling task in the scheduling job; and S5, publishing the scheduling job and starting execution. According to the publishing method, the design of the task executor is adopted; multiple task types and calling modes can be supported, internal implementation ofprograms of different languages and different types is shielded, only how to execute and call the tasks needs to be paid attention to, and even after program codes are changed and set and other languages are adopted for reconstruction, the scheduling tasks can still be reissued only by simply adjusting calling configuration information.

Owner:SHANDONG INSPUR GENESOFT INFORMATION TECH CO LTD

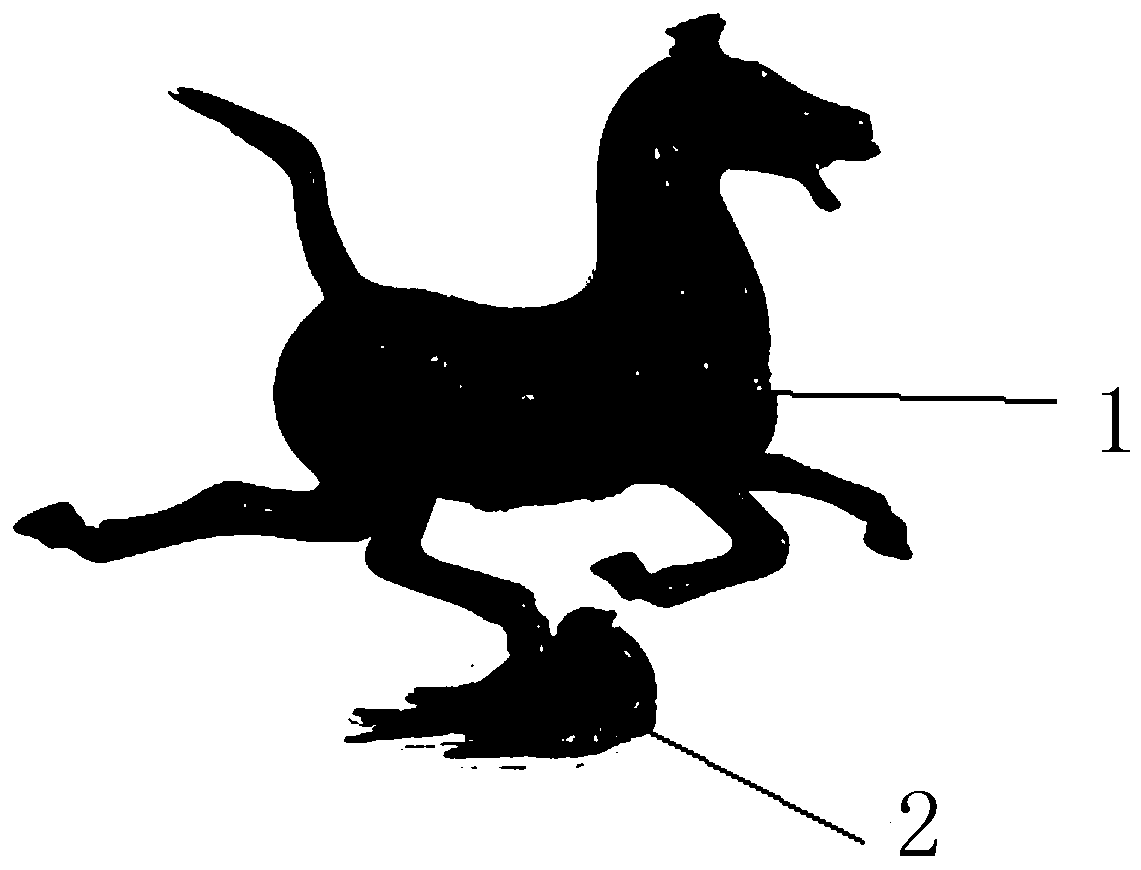

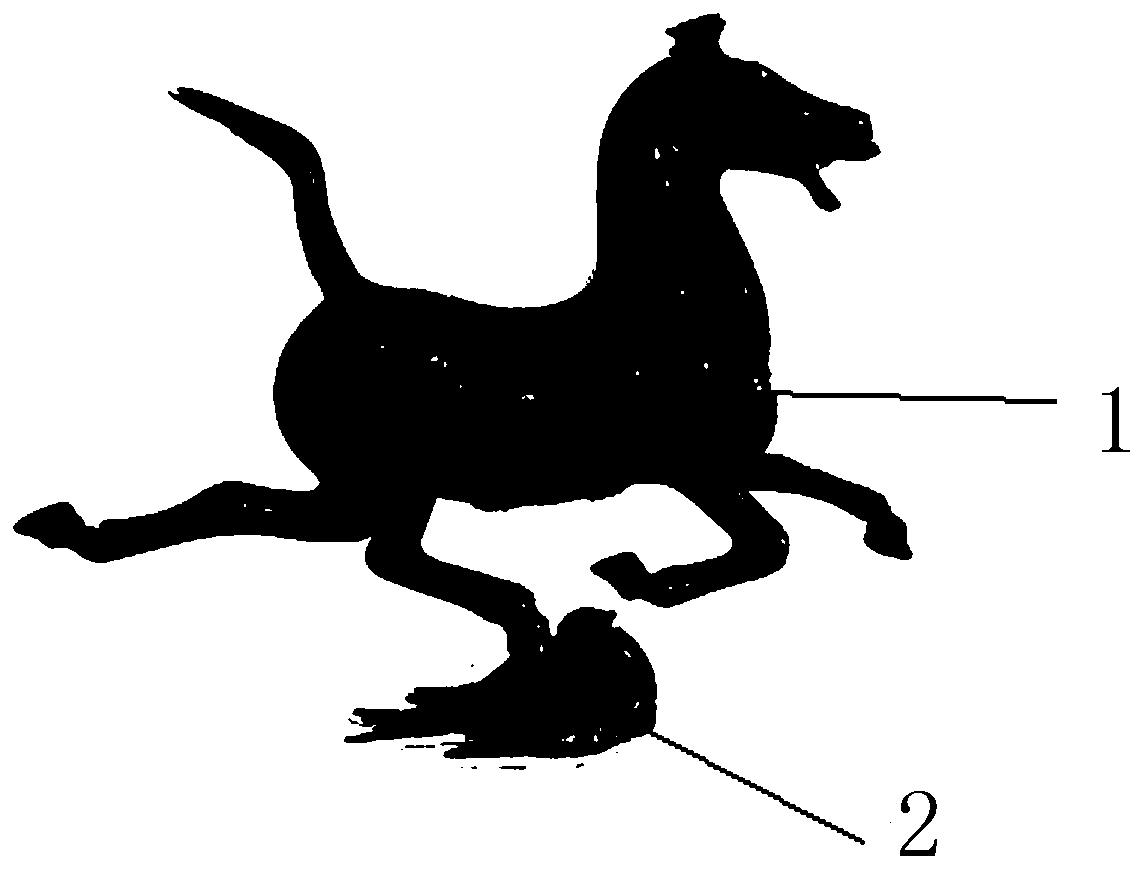

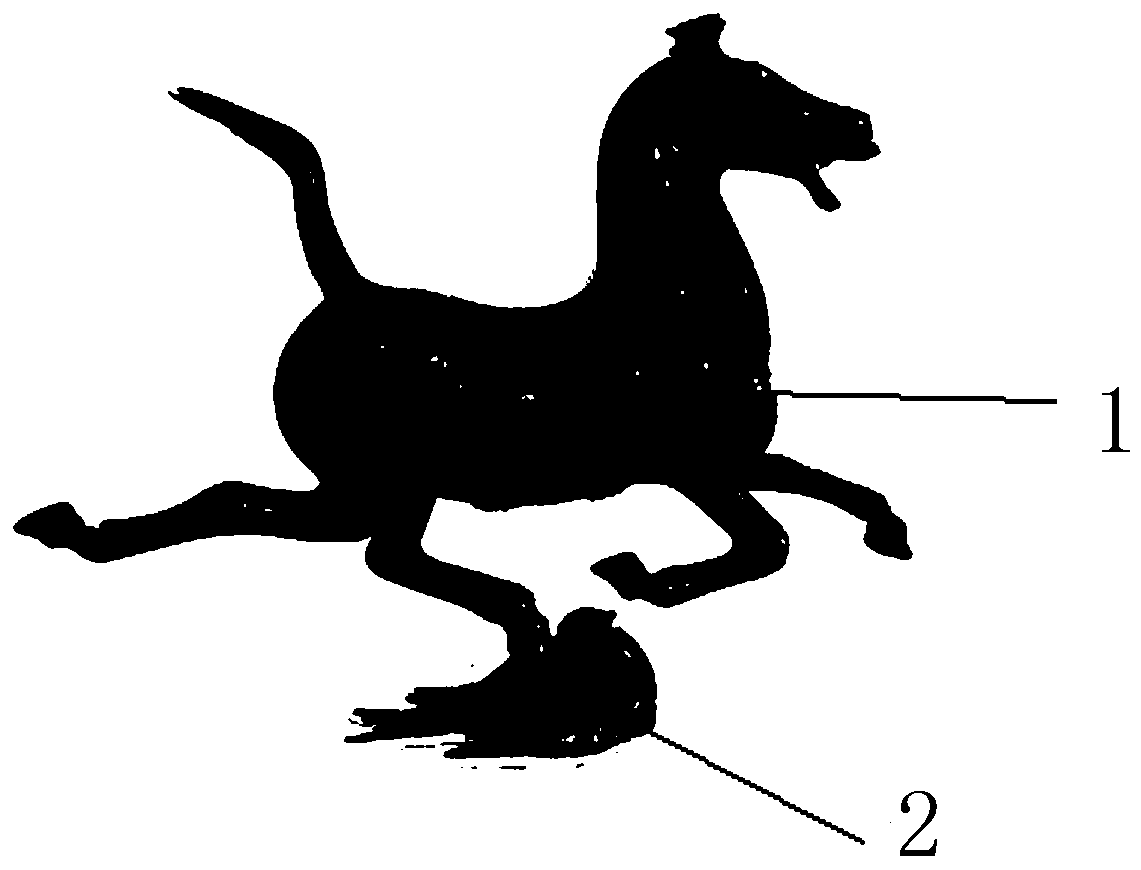

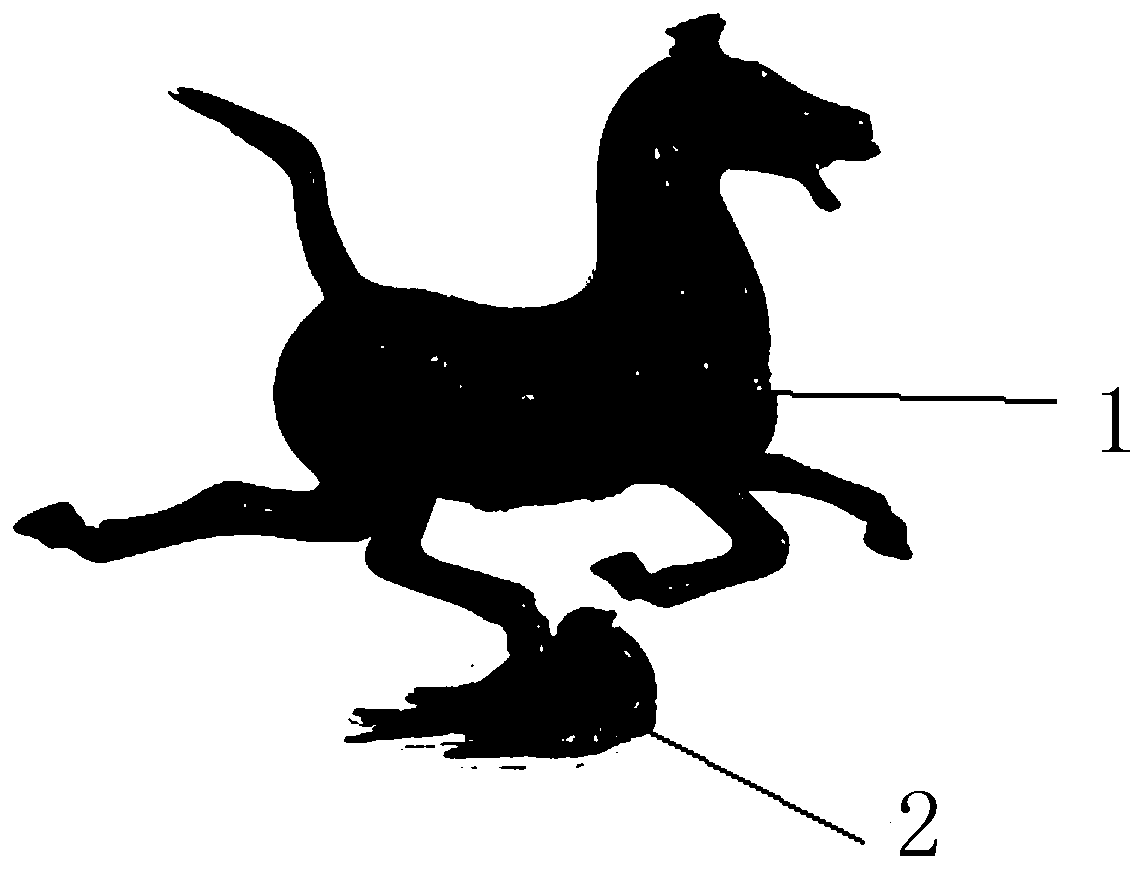

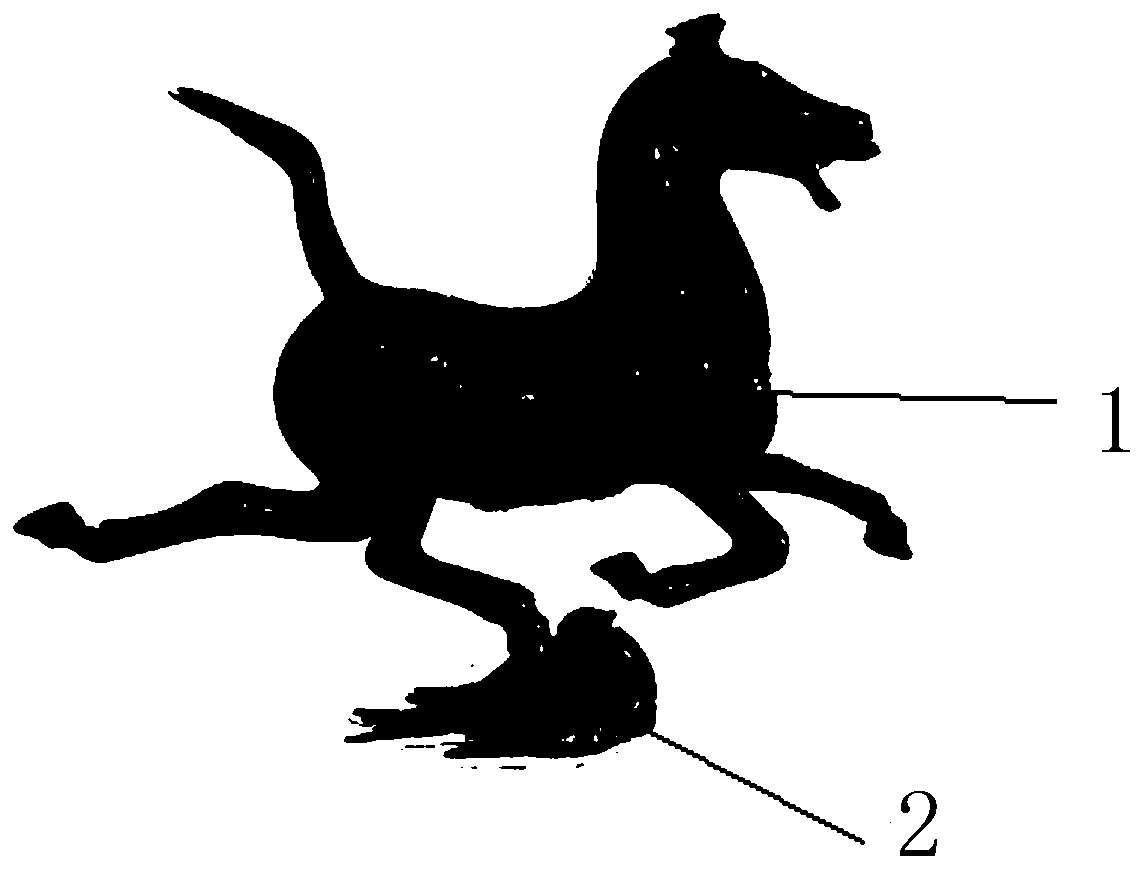

Manufacturing method of horse stepping on flying swallow type jun porcelain artware

InactiveCN107554169AEmbody design thinkingOrnamental structuresSpecial ornamental structuresHirundinidaeCarving

The invention discloses a manufacturing method of horse stepping on flying swallow type jun porcelain artware, and belongs to the field of jun porcelain artware. The manufacturing method comprises thesteps of: (1) model carving; (2) mold manufacturing; (3) pottery clay selection; (4) pulping; (5) grouting; (6) shaping; (7) biscuit firing; (8) glazing; and (9) firing; in the step (1) a horse head,four horse legs, a horse tail, a horse body and a flying swallow in the shape of horse stepping on flying swallow are carved for molding; and the manufacturing method has the characteristics of reduction of the rejection rate and capability of fully embodying the works design ideas.

Owner:YUZHOU ZHENGYUJUN KILN CO LTD

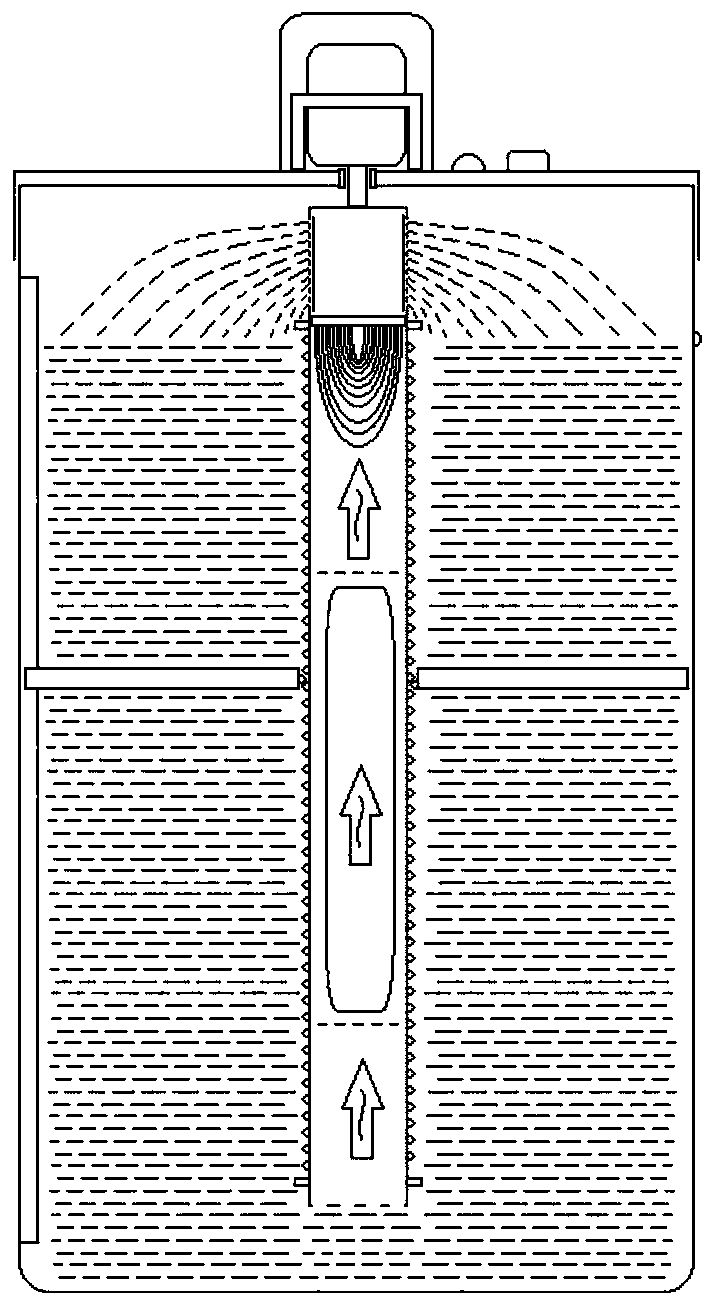

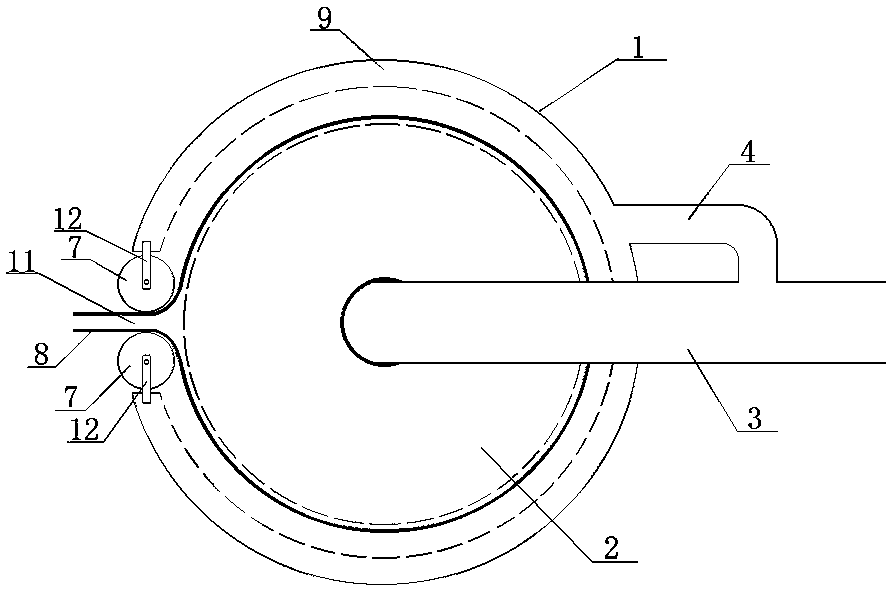

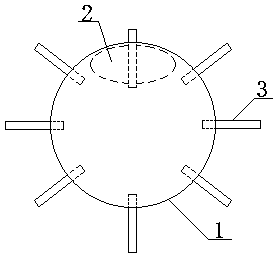

A portable environmental protection purification device

ActiveCN108408940BIncrease usage penetrationAvoid reverse flowWater/sewage treatment by centrifugal separationTreatment involving filtrationWater filterUltrafiltration

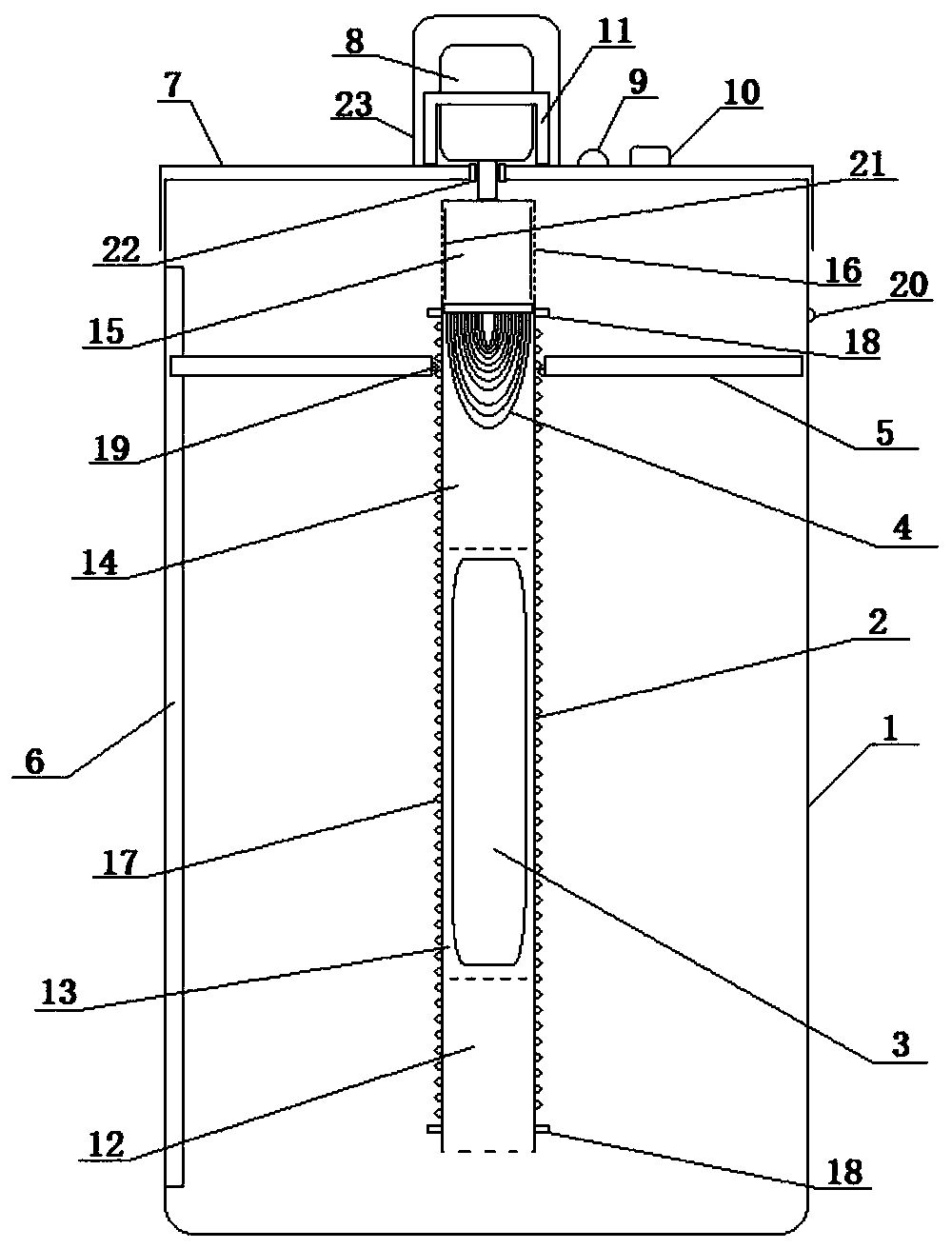

The invention relates to a portable environment-friendly purifying device, wherein a flow disturbing and pressure operation structure is designed, through rotating a water filtering pipeline (2) by arotating motor (8), and combining the limitation of a guiding bar (6) to the horizontal rotation of a disturbance plate (5), the disturbance plate (5) can move up and down along the water filtering pipeline (2), based on the downward movement of the disturbance plate (5), the pressure operation on water is realized, the water is sent to the water filtering pipeline (2) through an opening end at the bottom of the water filtering pipeline (2), and then is filtered through a specified filter element device (3) and a ultrafiltration membrane (4), meanwhile, the centrifugal movement is realized through the rotating of the water filtering pipeline (2), so that water in a centrifuging region (15) can be output through a hollow strusture and reflow to a main bottle body (1), at the same time, theup and down movement of the disturbance plate (5) can accelerate the full mixing of filtered water; for the water in the main bottle body (1), the repeated circulating between the bottle and a water filtering device is realized, and the circulating and purifying of water in the main bottle body (1) are realized.

Owner:JIANGSU LVDI ENVIRONMENTAL PROTECTION FILTER

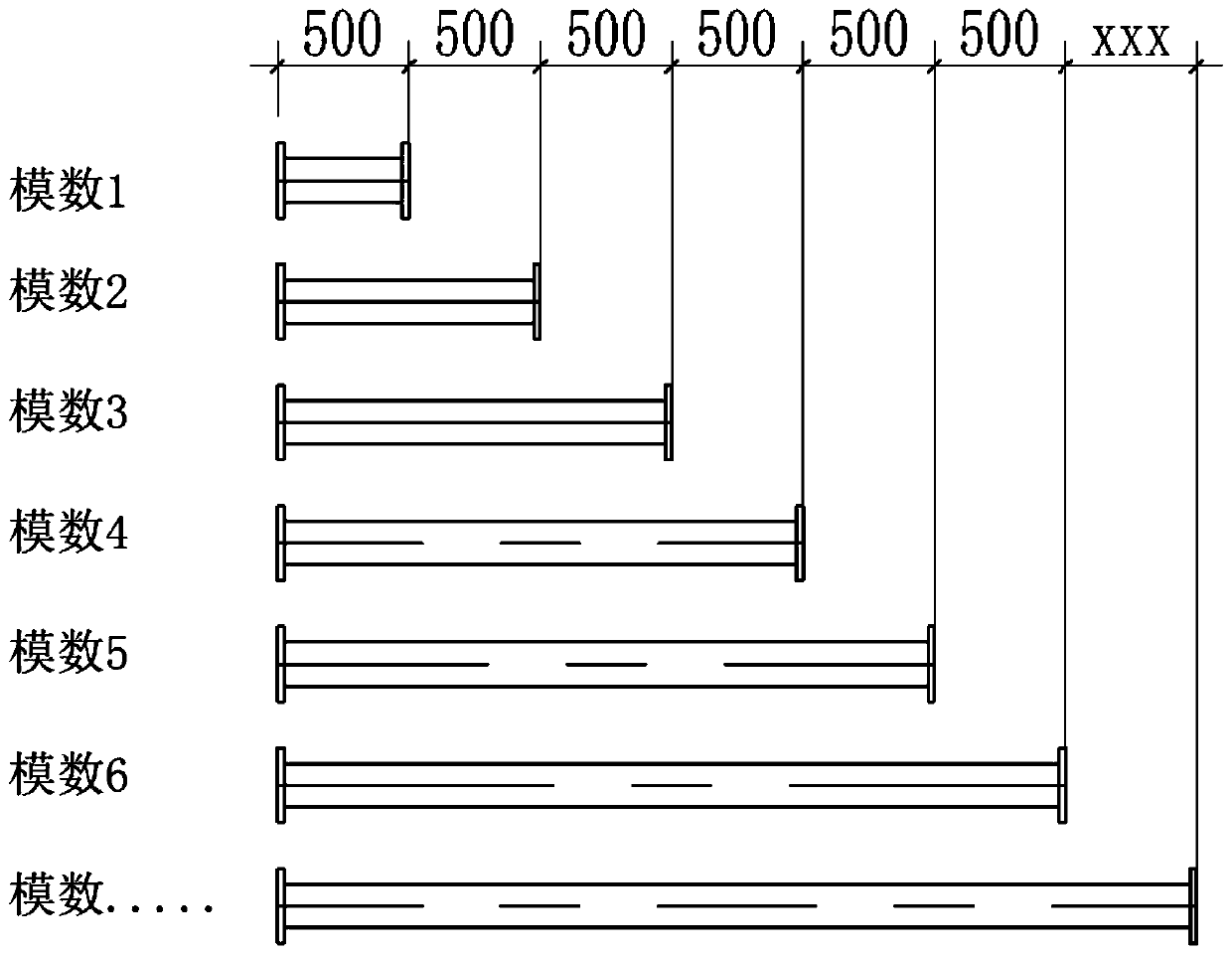

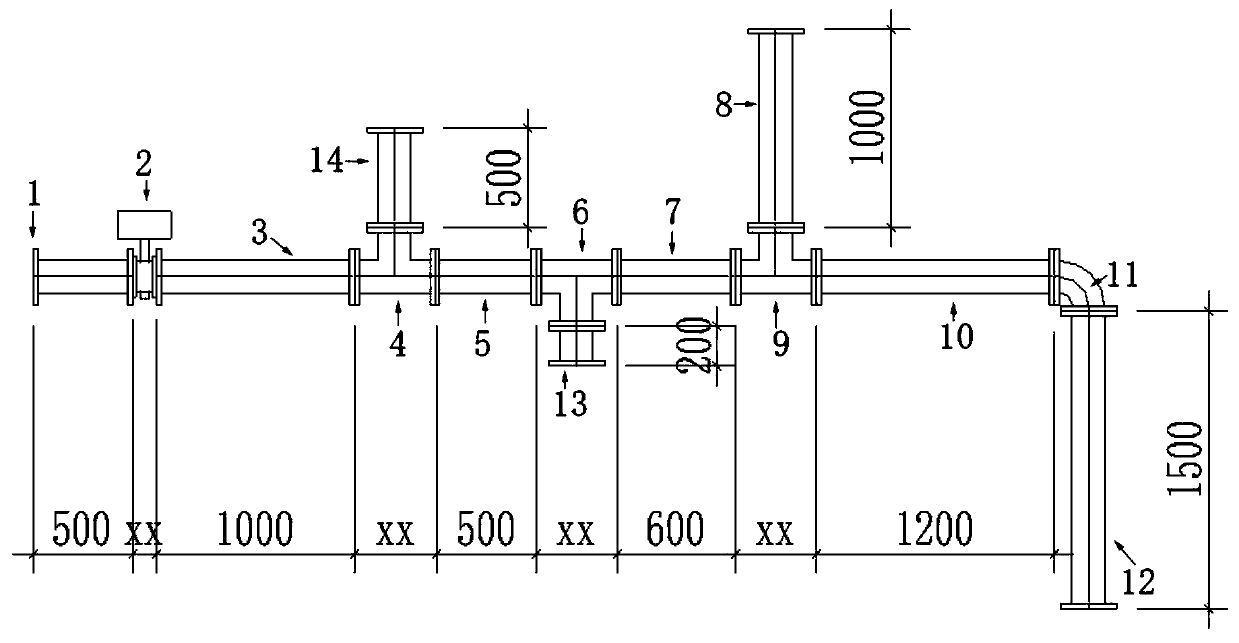

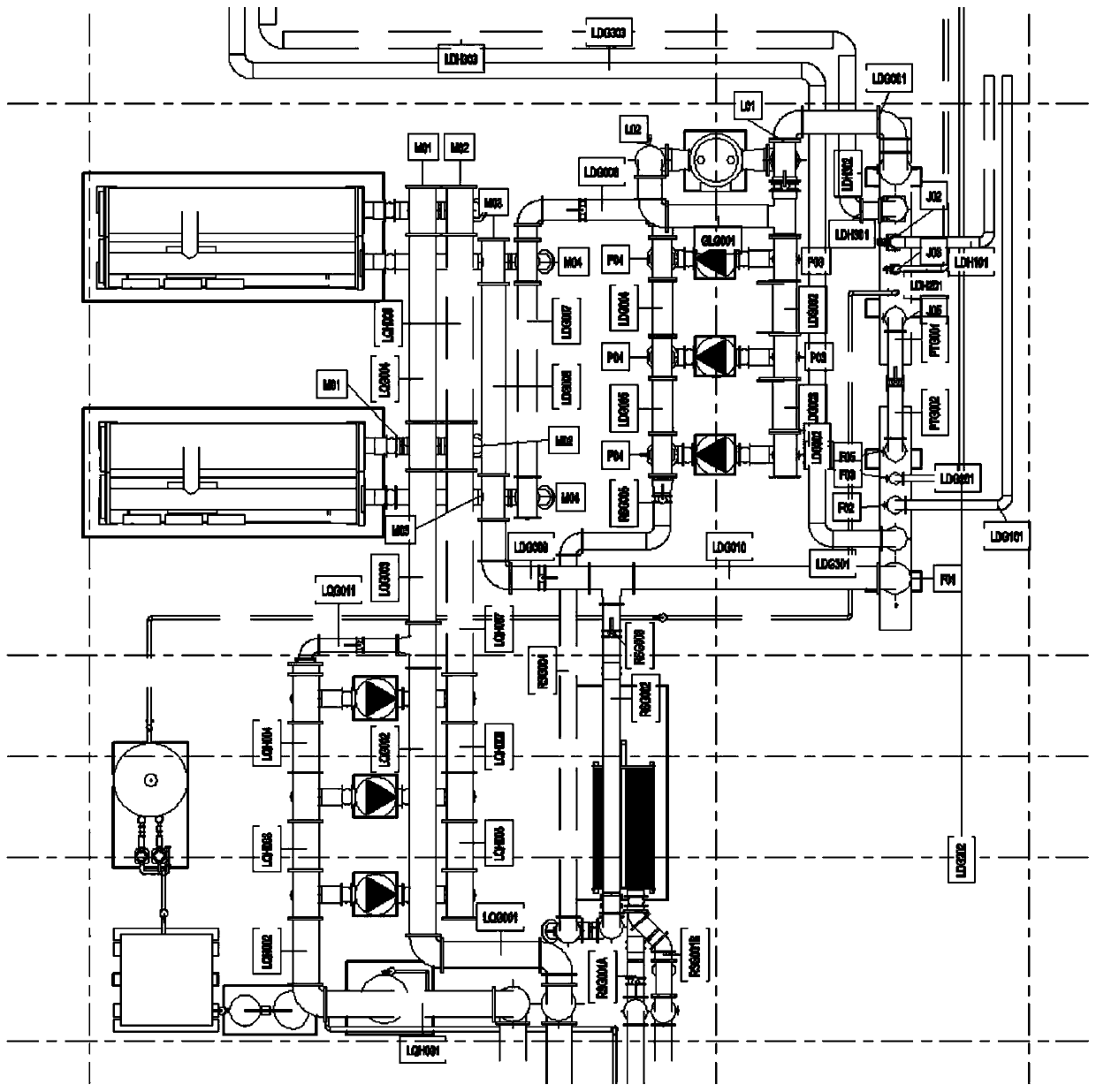

Standard modularized electromechanical pipeline assembling method based on BIM

InactiveCN110375113AIncrease productivityEliminate CollisionsGeometric CADPipe laying and repairPipe fittingFire safety

The invention discloses a standard modularized electromechanical pipeline assembling method based on BIM. The modularized design is performed by BIM, all pipeline components in a building mechanical and electrical project are disassembled into standard modularized pipe sections, the pipeline sections with the same pipe diameters have the same moduli, and are general mutually, and the type number of the pipe sections is greatly reduced. The volume production of the pipe sections in a factory can be realized, and the customization of all the pipe sections is not required. The standard modularized pipe sections produced in batches are transported to a project site to be assembled. Compared with the prior art, the standard modularized electromechanical pipeline assembling method has the advantages that automatic cutting and welding are performed on a machine tool of a factory, and on one hand, the processing precision and quality are greatly improved, on the other hand, the production efficiency is greatly improved. By adopting a mode of production in a factory and assembling on site, the environment pollution and hidden danger of fire safety of a construction site are eliminated. Thepipe sections and pipe fitting are subjected to standard modularization, the generality of the pipe sections is enhanced, the reject ratio of pipe section is greatly reduced, meanwhile the productionefficiency of the factory is improved, and the mounting efficiency of a mounting site is improved.

Owner:北京毕亦可机电设计咨询有限公司

Manufacturing method of jun porcelain artware in shape like galloping horse treading on flying swallow

InactiveCN107757223AEmbody design thinkingOrnamental structuresSpecial ornamental structuresMaterials scienceEquus ferus caballus

The invention discloses a manufacturing method of jun porcelain artware in a shape like a galloping horse treading on a flying swallow and belongs to the field of jun porcelain artware. The manufacturing method comprises the following steps: 1, engraving a model; 2, manufacturing a mould; 3, choosing pottery clay; 4, pulping; 5, grouting; 6, shaping; 7, bisque firing; 8, glazing; 9, firing, wherein a firing process of the step 9 is divided into four stages, and a fourth stage is a cooling stage; wherein in a cooling process, temperature is quickly cooled at first, the temperature is raised by20 DEG C to 30 DEG C when the temperature is reduced by 50 DEG C, and then the temperature is slowly cooled to natural temperature. The manufacturing method has the characteristics of preventing a finished product from cracking and improving a rate of finished products.

Owner:YUZHOU ZHENGYUJUN KILN CO LTD

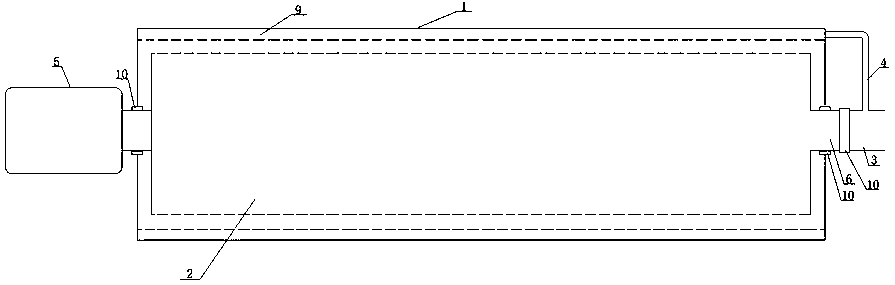

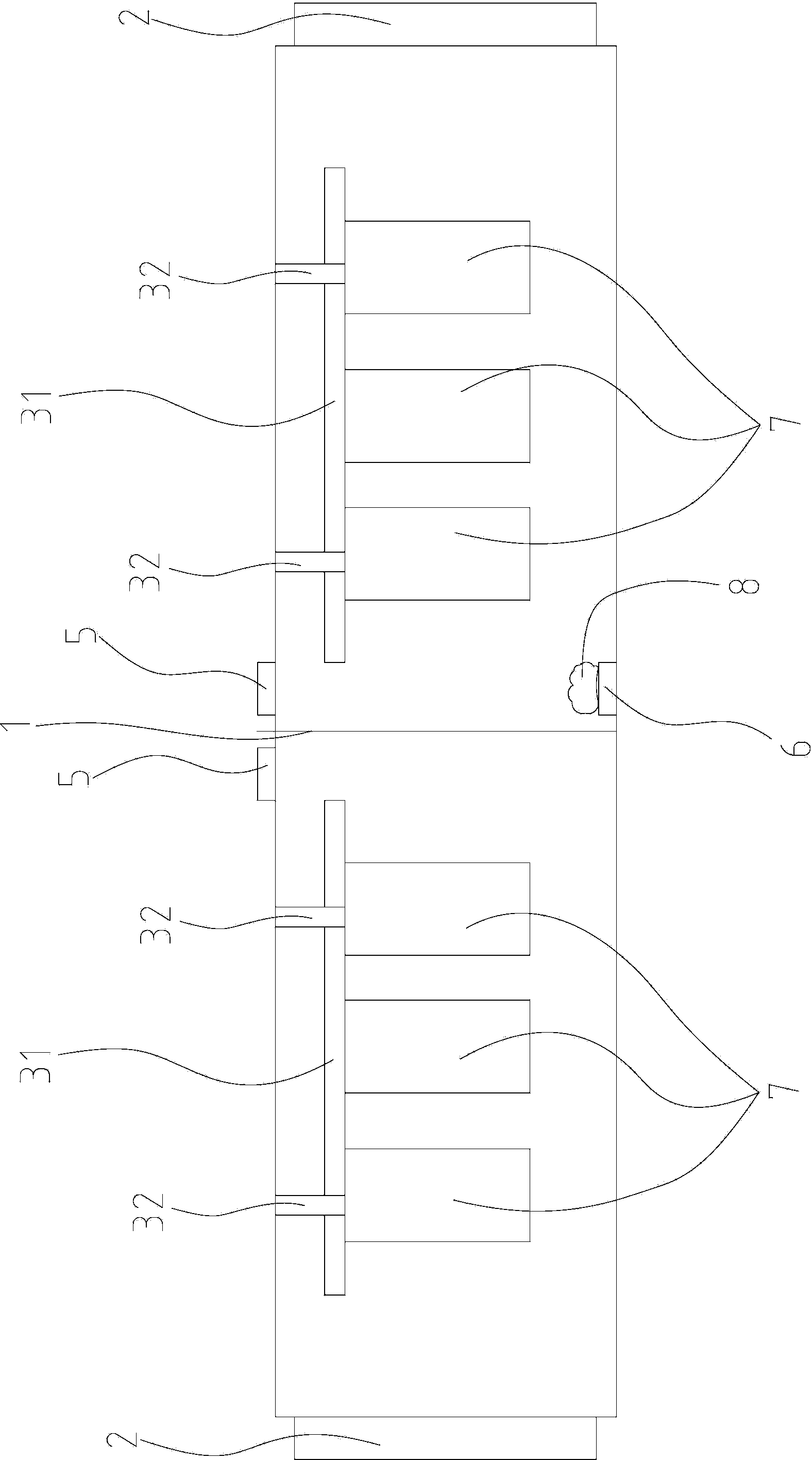

Drum and multilayer type woven fabric drying oven for stentering and setting machine

InactiveCN110295470AEfficient heating effectReduce space footprintHeating/cooling textile fabricsStretchingEngineeringMechanical engineering

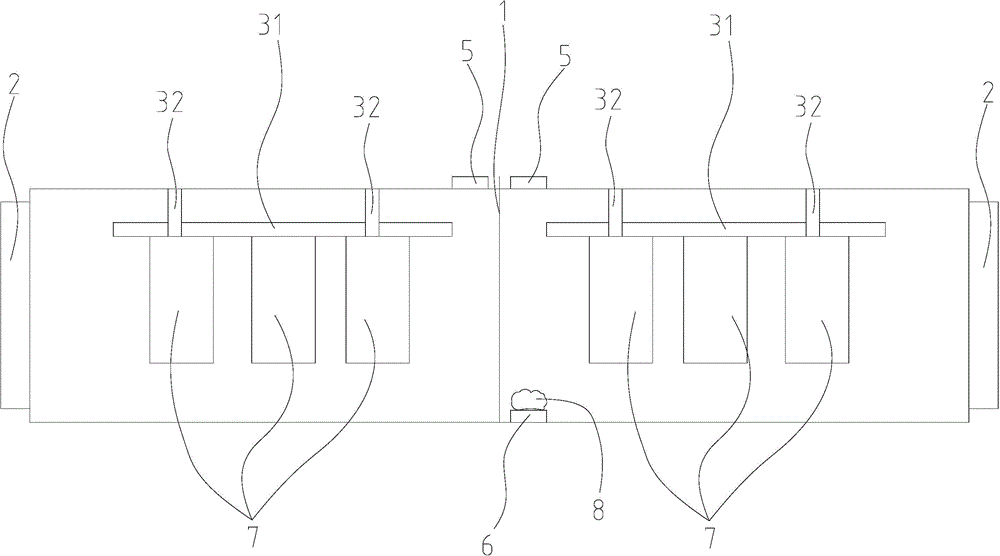

The invention relates to a drum and multilayer type woven fabric drying oven for a stentering and setting machine. The drum and multilayer type woven fabric drying oven is characterized in that an outer barrel (1) sleeves an inner drum (2), the position of the outer barrel (1) is fixed, the inner drum (2) is controlled by a motor (5) to rotate, woven fabric (8) is guided and conveyed to an area inside the outer barrel (1) and on the periphery of the inner drum (2) through two guide rollers (7) at the lateral open slot (11) of the outer barrel (1), hot air is conveyed into the inner drum (2) and the internal interlayer cavity (9) of the outer barrel (1), and wrapping type drying of the woven fabric (8) is achieved through air outlets. The drum and multilayer type woven fabric drying oven has the advantages that efficient woven fabric drying is achieved while the space occupation of the drying oven is reduced greatly, and convenient drying oven setting can be achieved.

Owner:JIANGSU HAIDA DYEING & PRINTING MACHINERY

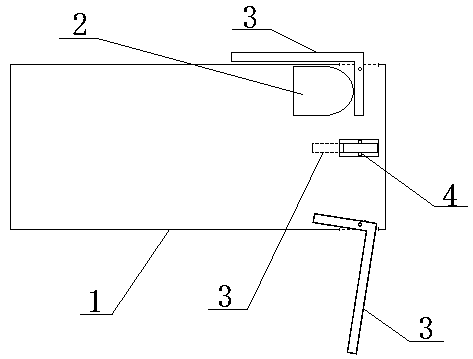

Multifunctional minitype molecular motion demonstration instrument

InactiveCN103150948AExpand the experimental operation surfaceExperimental dosage is smallEducational modelsChemical solutionEngineering

The invention relates to a multifunctional minitype molecular motion demonstration instrument which is a sealed transparent box body, wherein a drawing partition plate is arranged in the middle of the box body so that the box body is divided into a left cavity and a right cavity which are not communicated with each other; openings at left and right sides of the box body are respectively provided with a first choke plug which plays a role in sealing, and a suspension component is arranged at the inner side of the top wall of each cavity in a length direction; and a plurality of pieces of linearly-arranged test paper are hung on each suspension component, and a chemical solution dripping hole is formed on the top wall of each cavity and is sealed through a second choke plug. A gas molecular motion experiment and a liquid particle motion experiment can be conveniently and rapidly demonstrated in the demonstration instrument, and the two experiments are not influenced by each other. The demonstration instrument has the advantages of good demonstration effect, low experiment reagent dose and excellent promotional value.

Owner:刘畅

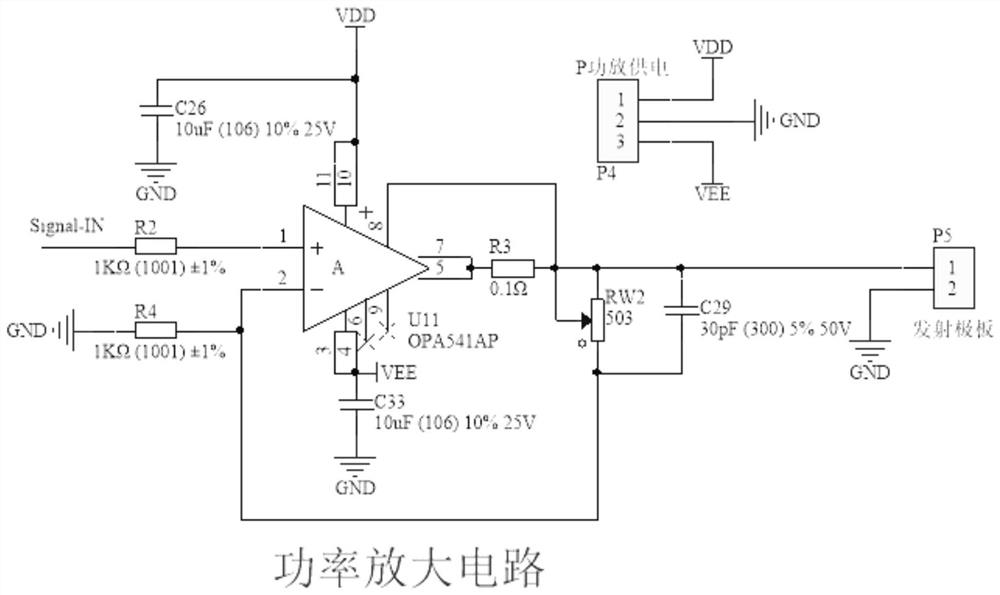

Underwater middle and long distance electric field communication system based on FSK modulation and demodulation

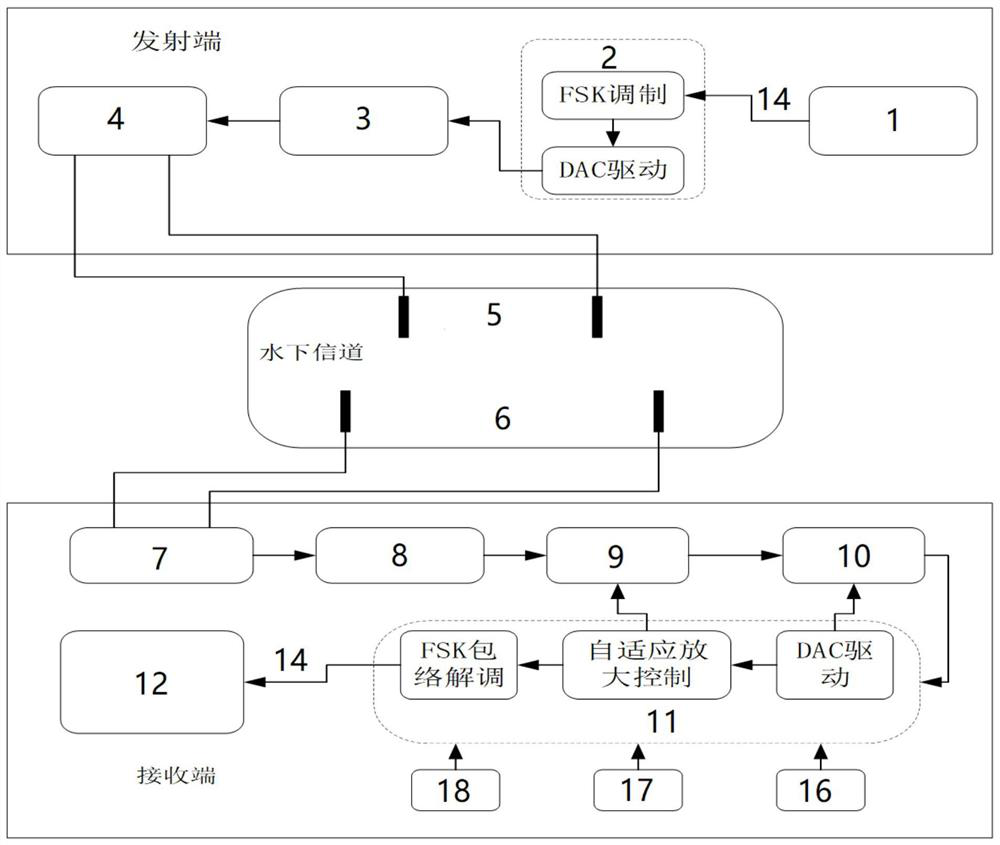

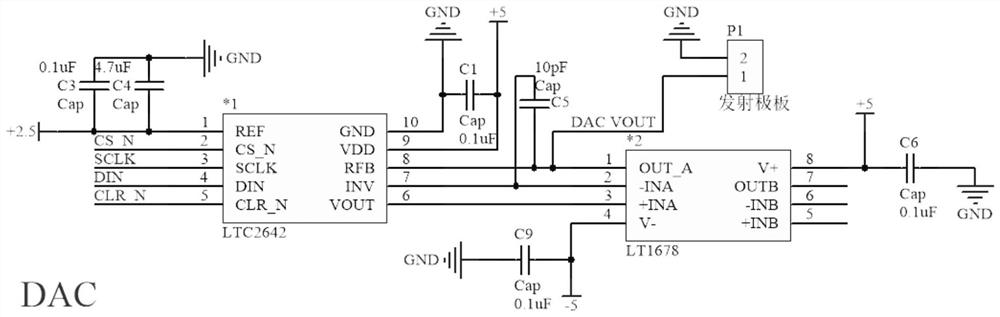

InactiveCN113660044ALarge emission currentControl electric field strengthFrequency-modulated carrier systemsCommunications systemComputer science

The invention discloses an underwater middle and long distance electric field communication system based on FSK modulation and demodulation, which is characterized in that an MCU is arranged at a transmitting end, adopts a 2FSK signal modulation and demodulation mode for communication and can transmit a serial port signal to an FPGA logic controller for signal modulation, and the modulated signal is subjected to digital-to-analog conversion and signal amplification and then is transmitted to an underwater channel through a transmitting electrode; signals emitted by the emitting electrode are received through the receiving electrode, are amplified, filtered and re-amplified in sequence, then are subjected to analog-to-digital conversion processing and then are input into the FPGA logic controller to be demodulated, the demodulated signals are transmitted into the MCU of the receiving end to complete communication, and the emitting end and the receiving end are respectively connected with a power management module. The system is suitable for communication between underwater communication equipment with small volume and low power consumption.

Owner:XI AN JIAOTONG UNIV

Manufacturing method of jun porcelain artware in shape like galloping horse treading on flying swallow

InactiveCN107759201AEmbody design thinkingOrnamental structuresSpecial ornamental structuresMaterials scienceHirundinidae

The invention discloses a manufacturing method of jun porcelain artware in a shape like a galloping horse treading on a flying swallow and belongs to the field of jun porcelain artware. The manufacturing method comprises the following steps: 1, engraving a model; 2, manufacturing a mould; 3, choosing pottery clay; 4, pulping; 5, grouting; 6, shaping; 7, bisque firing; 8, glazing; 9, firing, wherein in the step 7, green body shapes of the horse and the flying swallow shaped in the step 6 are respectively put into a bisque firing furnace to be bisque fired, the green body shapes are fired underthe temperature of 970 DEG C to 1000 DEG C for 4.5 to 6 hours, and the green body shapes are stopped being fired and naturally cooled for 10 hours. The manufacturing method has the characteristics ofkeeping a parison stable and reducing middle damage.

Owner:YUZHOU ZHENGYUJUN KILN CO LTD

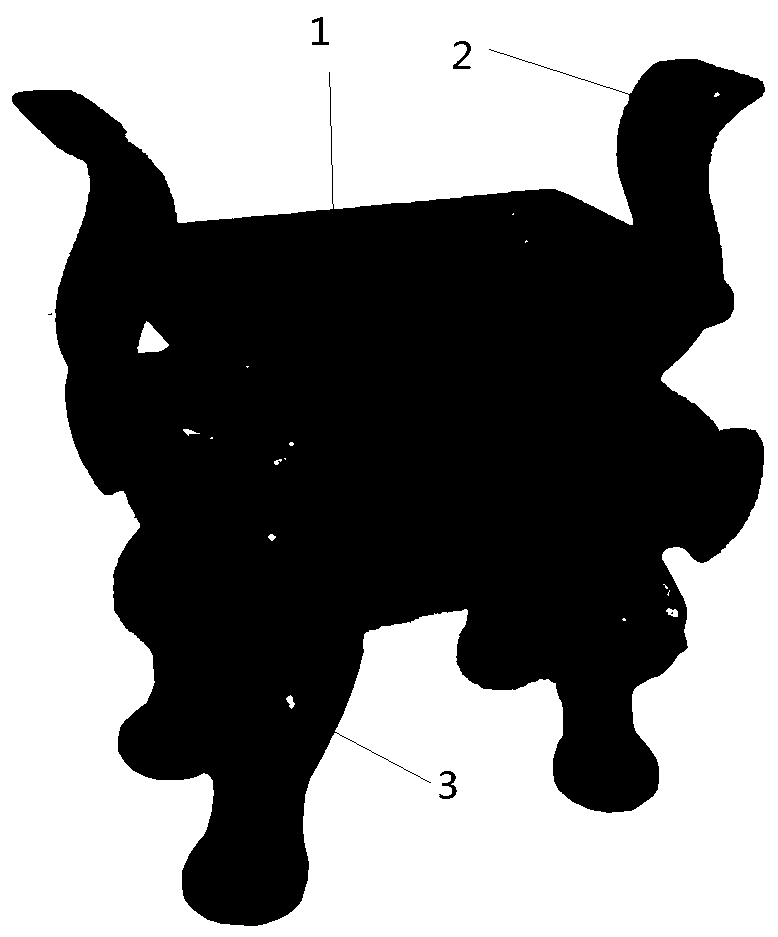

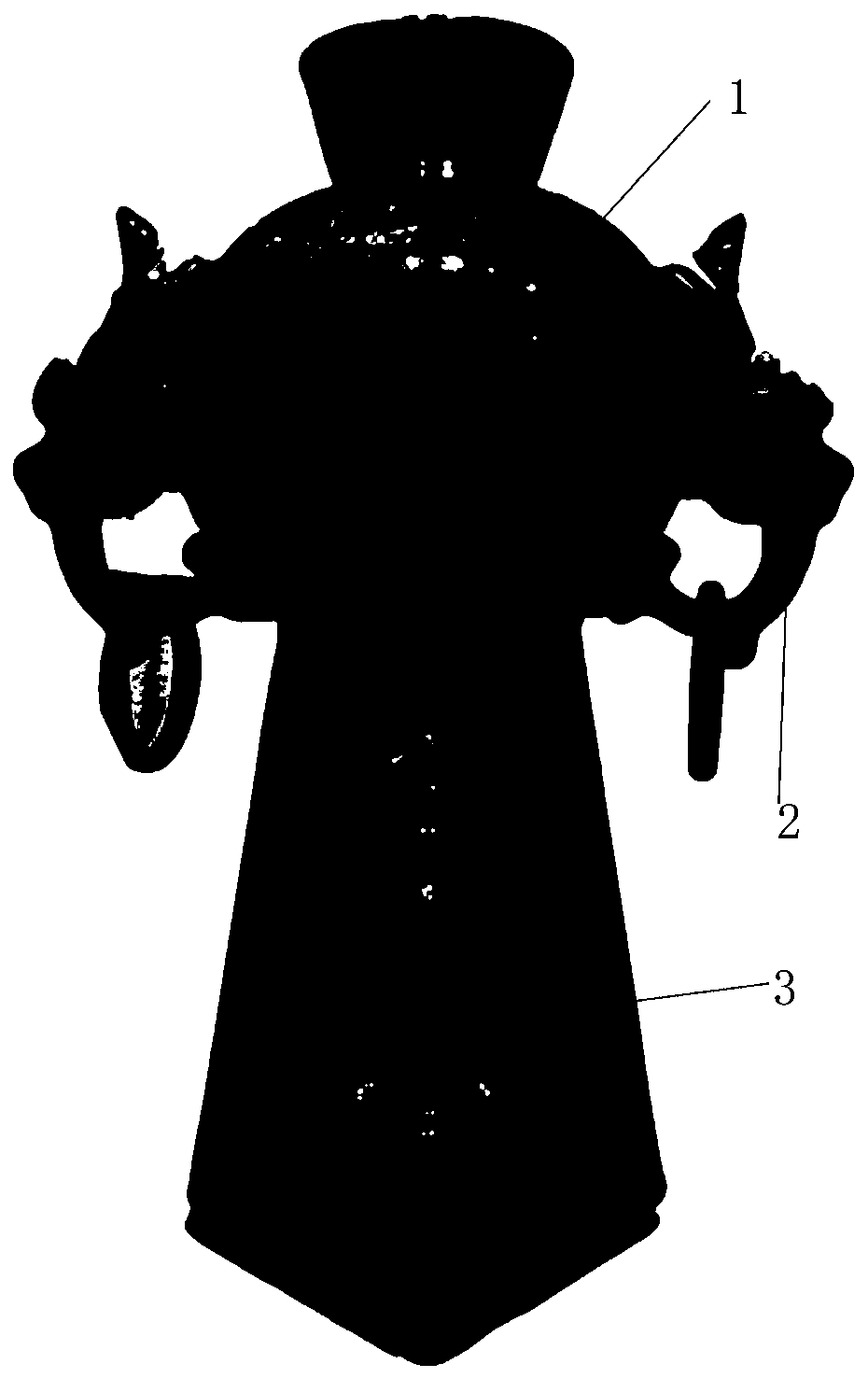

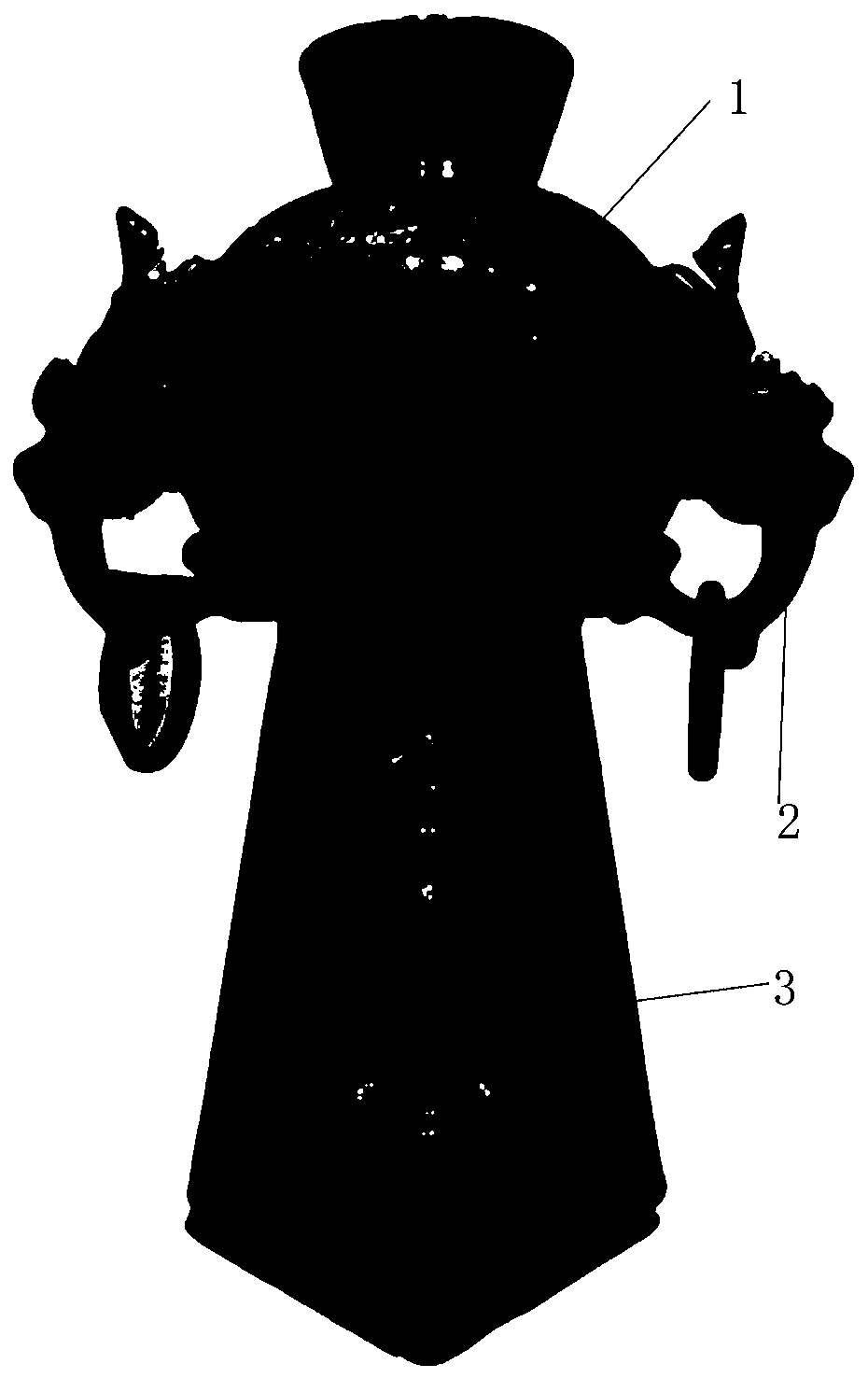

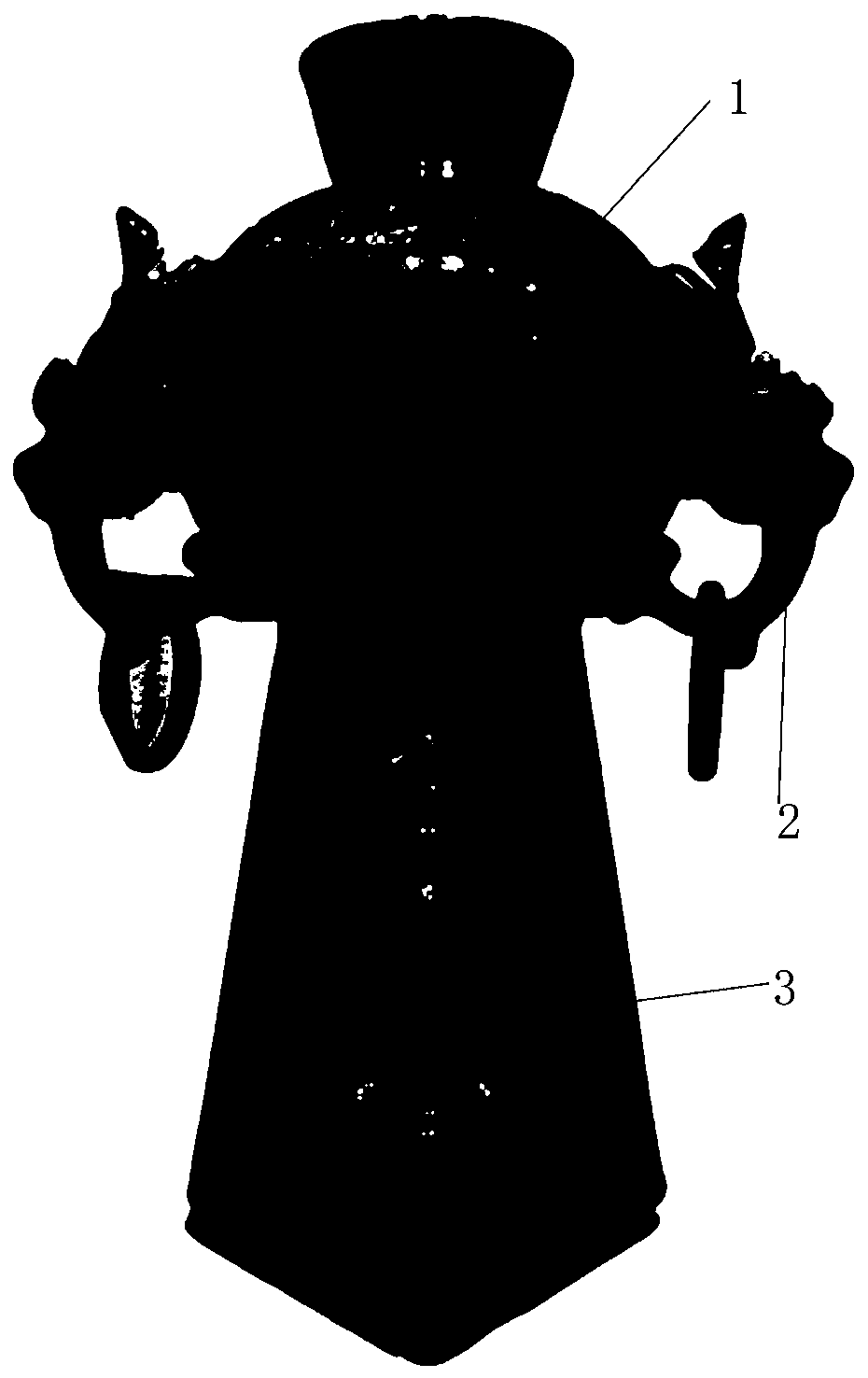

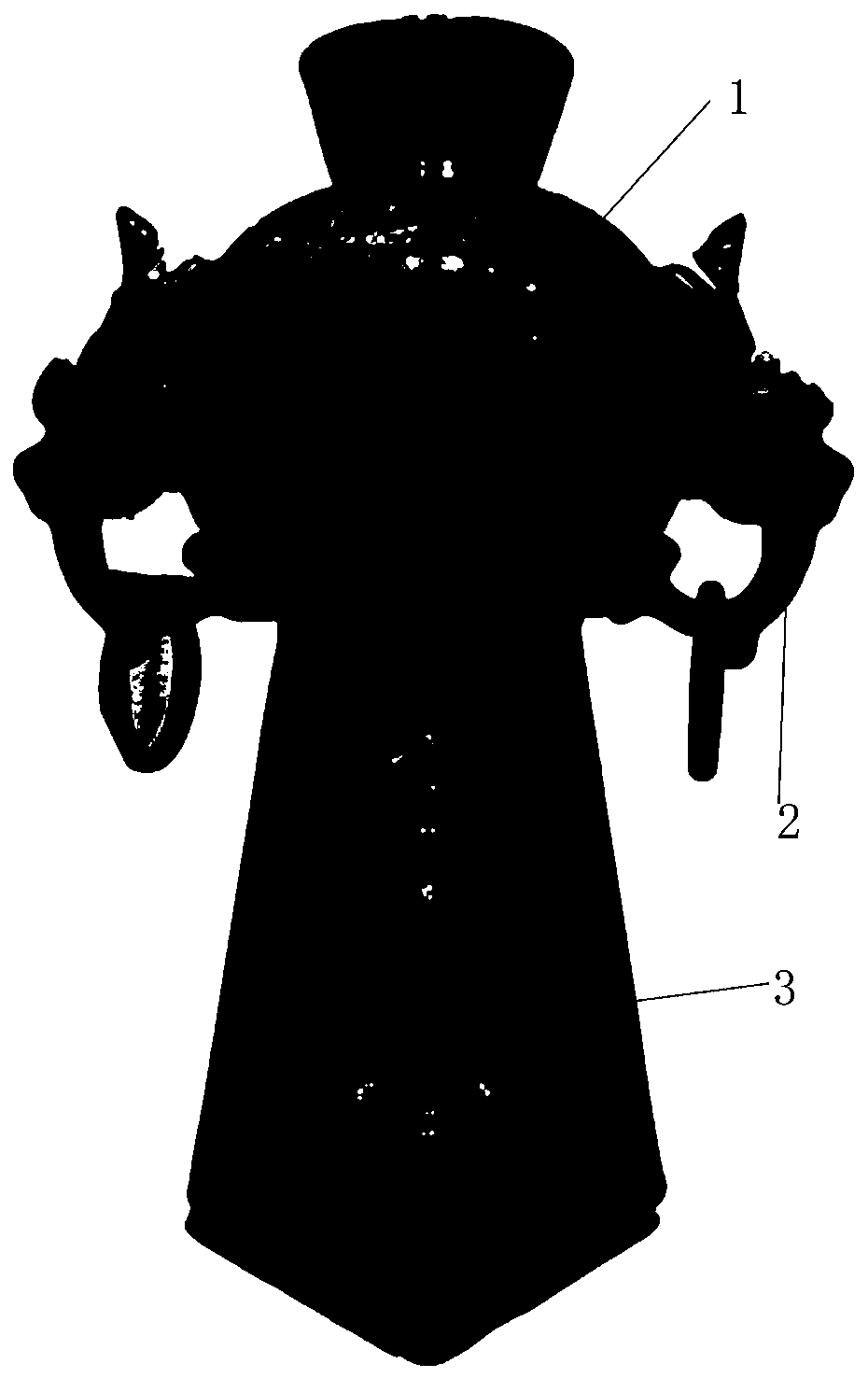

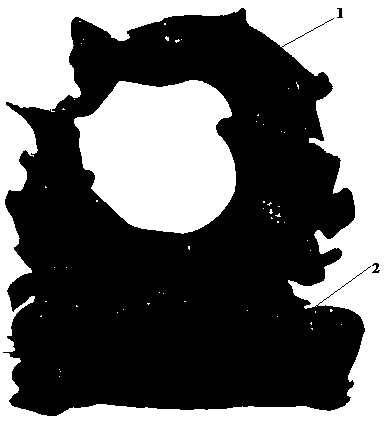

Manufacturing method of Jun porcelain artware in auspicious ding shape

InactiveCN108859555AEmbody design thinkingOrnamental structuresCeramic shaping apparatusHigh aluminumMaterials science

The invention provides a manufacturing method of Jun porcelain artware in an auspicious ding shape. The manufacturing method is characterized by comprising the following steps of: (1) engraving a model; (2) manufacturing a mold; (3) selecting argil; (4) preparing slurry; (5) pouring the slurry; (6) regulating the shape; (7) carrying out biscuiting; (8) carrying out glazing; and (9) carrying out sintering, wherein in the step (3), the argil selected for manufacturing a blank model is high-aluminum soil, and moreover 5% to 10% of aluminum and 5% to 10% of silicon are added to the high-aluminum soil.

Owner:YUZHOU ZHENGYUJUN KILN CO LTD

Manufacturing method of jun porcelain craft in ten-hand avalokitesvara shape

InactiveCN109318646AEmbody design thinkingOrnamental structuresSpecial ornamental structuresCarvingMaterials science

The invention discloses a manufacturing method of a jun porcelain craft in a ten-hand avalokitesvara shape, and belongs to the field of jun porcelain crafts. The manufacturing method comprises the steps of 1, model carving; 2, die manufacturing; 3, argil selecting; 4, pulping; 5, grouting; 6, shaping; 7, biscuit firing, 8, glazing, and 9, firing, wherein the step 4 comprises the steps of smashingargil into powder with the fineness of 220 meshes, after mixing, adding water into the smashed argil and stirring to obtained pulp, and filtering the pulp for grouting in the next step.

Owner:ZHENGZHOU JIAYIBEI PACKAGING DESIGN CO LTD

Manufacturing method of jun porcelain artware with shape of horse stepping on flying swallow

InactiveCN107599722AEmbody design thinkingOrnamental structuresSpecial ornamental structuresMaterials scienceCarving

The invention discloses a manufacturing method of jun porcelain artware with a shape of a horse stepping on a flying swallow, and belongs to the field of jun porcelain artware. The manufacturing method comprises the steps of: (1) model carving; (2) mold manufacturing; (3) pottery clay selection; (4) pulping; (5) grouting; (6) patching; (7) biscuit firing; (8) glazing; and (9) burning; in the step(6), a hollow blank reaching a designed thickness by grouting is taken out from a mold; the horse head, the horse tail, four horse shoes and the horse body are bonded according to design requirements;the flying swallow is single; and the surface of the blank is manually finished smoothly without defects. The manufacturing method has the characteristics of simple modeling, reduction of the manufacturing cost, increment of the yield and full embodiment of key design points.

Owner:YUZHOU ZHENGYUJUN KILN CO LTD

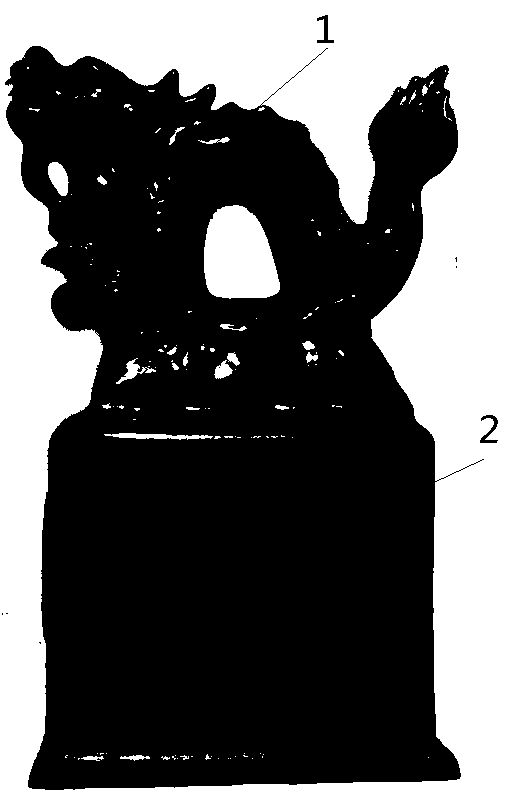

Manufacturing method of dragon-shaped Jun porcelain artwork

InactiveCN109265134AEmbody design thinkingSpecial ornamental structuresClaywaresEngravingMaterials science

The invention relates to a manufacturing method of a dragon-shaped Jun porcelain artwork, and belongs to the field of Jun porcelain artworks. The manufacturing method comprises the following steps: 1,engraving of a model; 2, manufacturing of a mold; 3, selecting of porcelain clay; 4, manufacturing of slurry; 5, injecting of the slurry; 6, trimming; 7, biscuit firing; 8, applying of glaze; 9, firing: combining and adhering a dragon and a base blank after glaze applying in step 8 according to a shape of the dragon treading on a base, putting into a kiln, and firing. The manufacturing method hasthe advantage that the characteristics of Jun porcelain are fully presented in the design of the dragon seal shape, and the design concept of the dragon seal artwork can be well realized.

Owner:禹州市元丰钧陶瓷有限公司

Production method for Jun porcelain handicraft product having Chinese bottle model

InactiveCN109249740AEmbody design thinkingDecorative surface effectsSpecial ornamental structuresPotassiumEngineering

The invention relates to a production method for a Jun porcelain handicraft product having a Chinese bottle model, and belongs to the field of Jun porcelain handicraft products. The production methodcomprises: 1, carving models; 2, making molds; 3, selecting pot clay; 4, pulping; 5, grouting; 6, patching; 7, carrying out biscuit firing; 8, glazing; and 9, firing, wherein the ball body uses a traditional coal-fired furnace transmutation glaze, and the glaze comprises 30-40% of yellow feldspar, 10-15% of a glaze agent, 4-7% of talc, 5-10% of red feldspar, 3-8% of zinc oxide, 8-12% of potassiumfeldspar, 3-5% of malachite, and 0.5-2% of tin oxide.

Owner:许昌市金堂钧瓷文化发展有限公司

Manufacturing method of ten-finger Avalokitesvara-shaped Jun porcelain artware

InactiveCN109318647AEmbody design thinkingOrnamental structuresSpecial ornamental structuresCarvingMaterials science

The invention discloses a manufacturing method of ten-finger Avalokitesvara-shaped Jun porcelain artware, and belongs to the field of Jun porcelain artware. The manufacturing method comprises the steps of (1) model carving, (2) mold manufacturing, (3) argil selection, (4) pulping, (5) grouting, (6) modeling, (7) biscuiting, (8) glazing and (9) firing; in the step (7), blanks finished in the step (6) of the ten-finger Avalokitesvara and the lotus throne are placed in a biscuiting kiln for biscuiting by 4.5-6 hours at a temperature of 970-1000 DEG C; and the fire is stopped for natural cooling by 10 hours to achieve the characteristics of maintaining the stability of the blanks and reducing the intermediate damage.

Owner:ZHENGZHOU JIAYIBEI PACKAGING DESIGN CO LTD

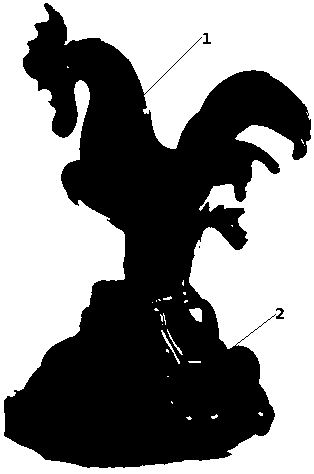

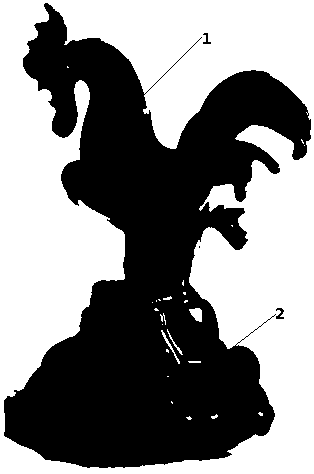

Method for manufacturing jun porcelain artware in shape of cock

InactiveCN108656833AEmbody design thinkingOrnamental structuresCeramic shaping apparatusSiliconHigh aluminum

The invention discloses a method for manufacturing jun porcelain artware in the shape of a cock, and belongs to the field of jun porcelain artware. The method comprises the following steps of 1, modelcarving; 2, mold manufacturing; 3, argil selection; 4, slurrying; 5, slip casting; 6, shape correction; 7, biscuiting; 8, glazing; and 9, firing. According to step 3, argil for manufacturing a base is selected and is high-aluminum soil, and in addition, 5% to 10% of aluminum and 5% to 10% of silicon are added into the high-aluminum soil.

Owner:YUZHOU ZHENGYUJUN KILN CO LTD

Manufacturing method for jun porcelain handiwork in form of horse stepping on flying swallow

InactiveCN107738535AEmbody design thinkingOrnamental structuresSpecial ornamental structuresCarvingMaterials science

The invention provides a manufacturing method for a jun porcelain handiwork in the form of a horse stepping on a flying swallow and belongs to the field of jun porcelain handiworks. The manufacturingmethod comprises the following steps of 1, model carving, 2, mold manufacturing, 3, argil selection, 4, pulping, 5, grouting, 6, shaping, 7, biscuiting, 8, glazing and 9, firing. In the fifth step, the green body pulp made in the fourth step is injected into a mold manufactured in the second step, layer-by-layer overlaying is adopted for green body manufacturing, it is guaranteed that the thickness of a green body model ranges from 3.5 mm to 4.5 mm, and the manufacturing method has the beneficial effects that the uniformity and consistency of the wall thickness of a parison can be kept, and the yield is increased.

Owner:YUZHOU ZHENGYUJUN KILN CO LTD

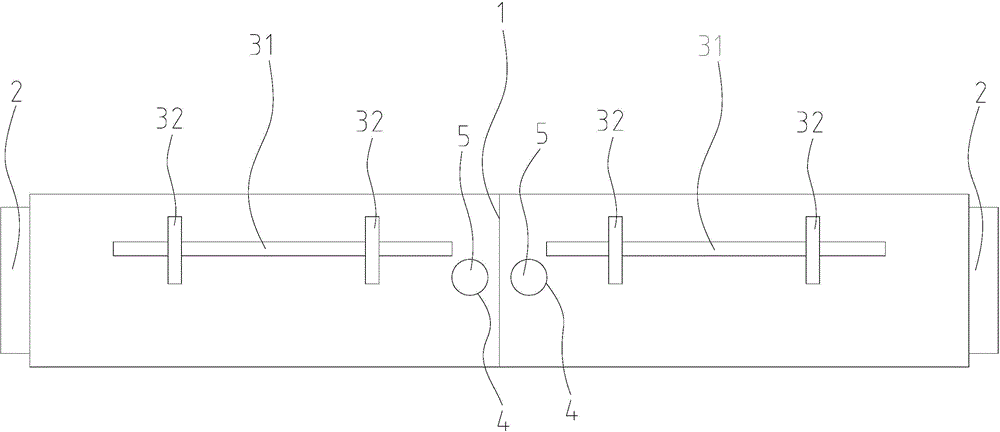

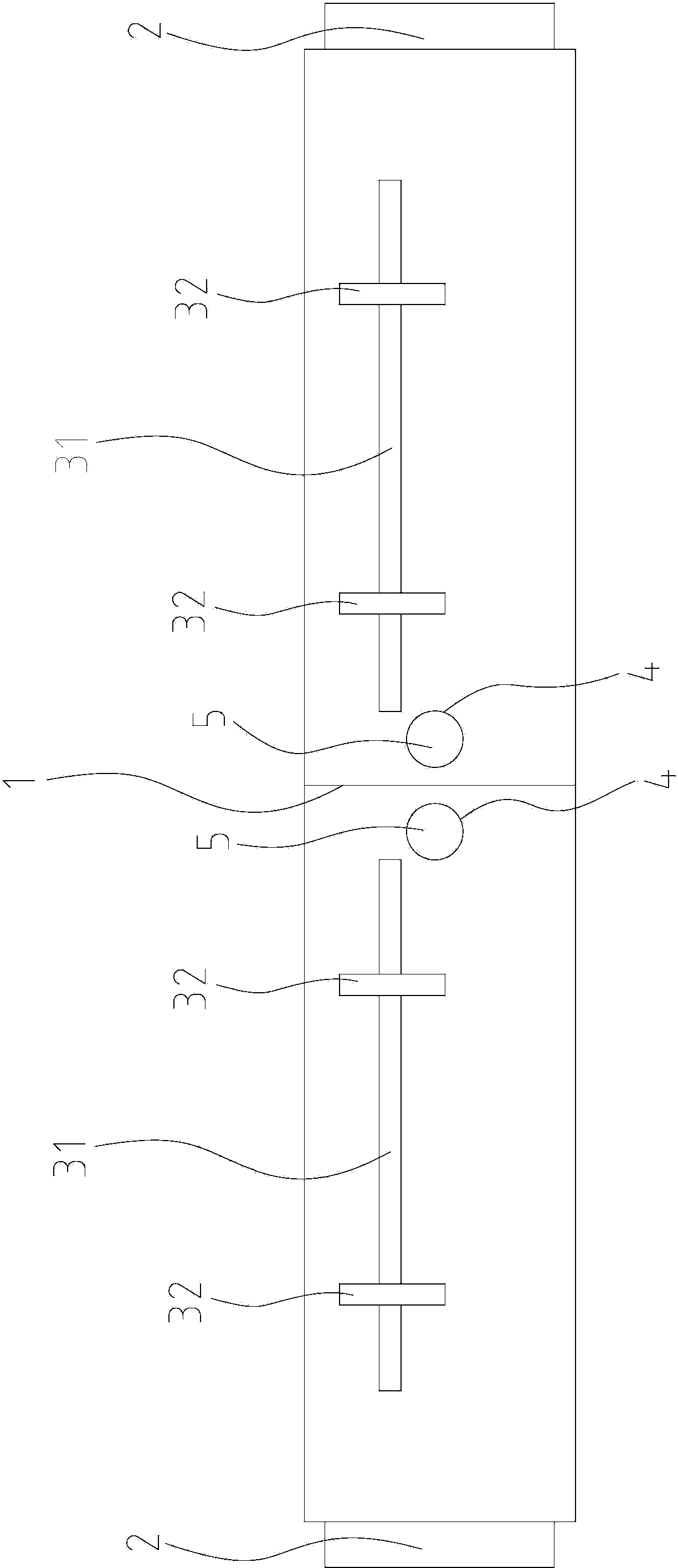

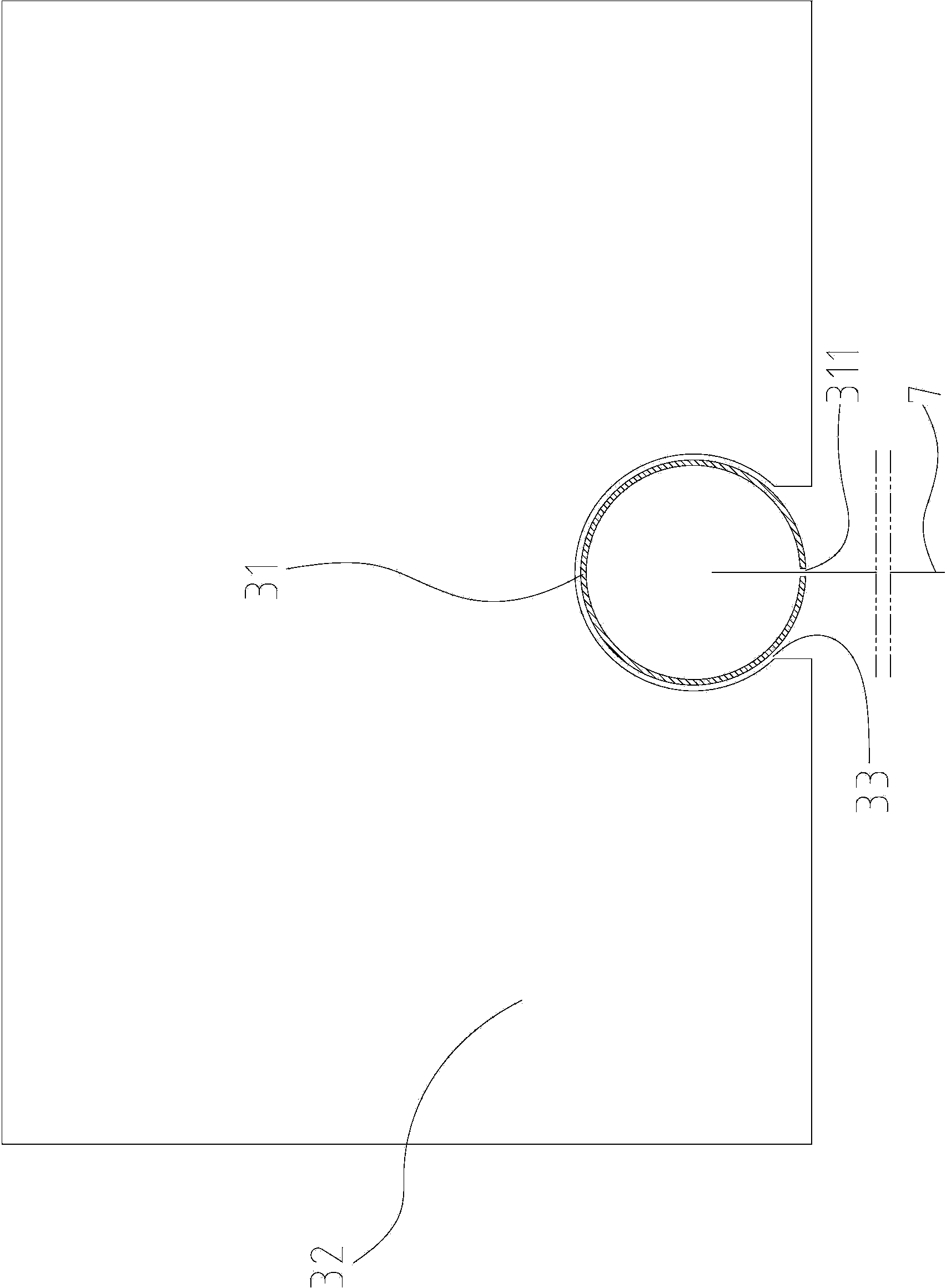

Mechanical compression driving shaft for tenter setting machine

InactiveCN110331542AAchieve compactionImprove transmission efficiencyHeating/cooling textile fabricsStretchingEngineeringContinuous rotation

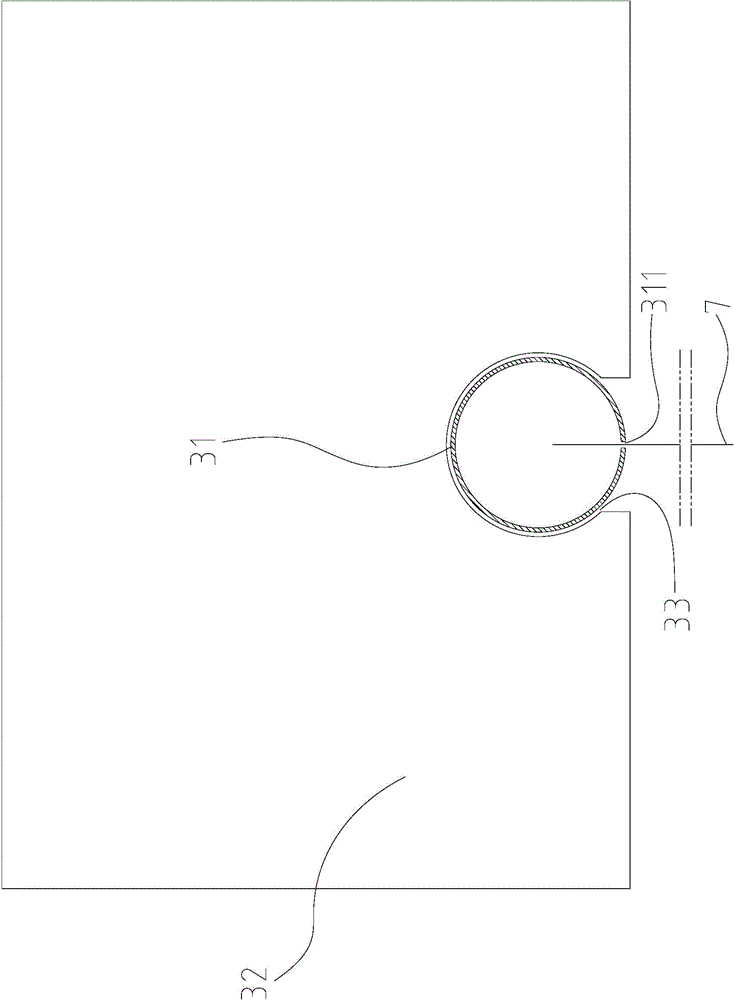

The invention relates to a mechanical compression driving shaft for a tenter setting machine. Based on the transmission structure of a roller (1), a mechanical power assisting device is introduced. Based on rotation of the roller (1) and a limiting effect of a designed stop block (2), each L-shaped rod (3) is designed to contact with the stop block (2) to rotate and perform limit during rotation with the roller (1), so that the long edges of the L-shaped rods (3) compress the edge of woven fabric, and two sides of the woven fabric are compressed; by continuous rotation of the roller (1), the woven fabric is supported and guided, conveying force is provided for the woven fabric to the greatest extent, and conveying efficiency of the woven fabric is greatly improved.

Owner:JIANGSU HAIDA DYEING & PRINTING MACHINERY

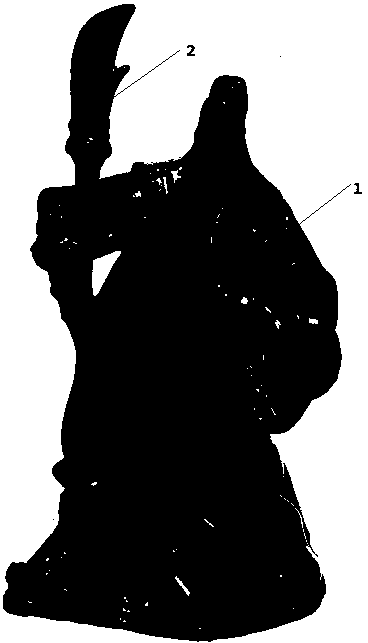

A method for manufacturing jun porcelain artware having a 'Gaun Yu' shape

InactiveCN109203814AEmbody design thinkingDecorative surface effectsSpecial ornamental structuresMaterials science

A method for manufacturing jun porcelain artware having a 'Gaun Yu' shape is provided, belonging to the field of jun porcelain artware. The method includes 1) model engraving, 2) mold manufacturing, 3) clay selecting, 4) pulp preparing, 5) casting, 6) patching, 7) biscuiting, 8) glazing, and 9) firing. The step 4) is a step of mixing and crushing clay selected in the step 3), with the crushing particle size being 200-300 meshes, adding water, stirring the mixture and filtering the mixture to obtain blank pulp.

Owner:禹州市元丰钧陶瓷有限公司

Production method of jun porcelain art craft with modeling of horse stepping on flying swallow

InactiveCN107586113AEmbody design thinkingOrnamental structuresSpecial ornamental structuresPotassium feldsparOxide

The invention discloses a production method of a jun porcelain art craft with a modeling of horse stepping on flying swallow. The production method is characterized by comprising the following steps:firstly, carving a model; secondly, producing a mould; thirdly, selecting clay; fourthly, preparing slurry; fifthly, injecting the slurry; sixthly, patching; seventhly, biscuiting; eighthly, glazing;ninthly, firing; in the eighth step, the horse adopts a traditional coal-fired transmutation glaze, wherein the glaze is prepared from 30 to 40 percent of melilite, 10 to 15 percent of local feldsparfrom Yuzhou, Henan, China, 4 to 7 percent of talcum, 5 to 10 percent of red feldspar, 3 to 8 percent of zinc oxide, 8 to 12 percent of potassium feldspar, 3 to 5 percent of malachite and 0.5 to 2 percent of stannic oxide. The preparation method disclosed by the invention has the characteristics that the activity of the horse in the horse stepping on flying swallow can be embodied by using jun porcelain color, and the connotation of the jun porcelain art craft with the modeling of horse stepping on flying swallow is enriched.

Owner:YUZHOU ZHENGYUJUN KILN CO LTD

Manufacturing method of jun porcelain artwork in Dhyana Mudra Buddha shape

InactiveCN109278458AEmbody design thinkingOrnamental structuresSpecial ornamental structuresSlurrySilicon

The invention provides a manufacturing method of a jun porcelain artwork in a Dhyana Mudra Buddha shape, and belongs to the field of jun porcelain artworks. The manufacturing method of the jun porcelain artwork in the Dhyana Mudra Buddha shape comprises the following steps of 1, model carving; 2, mold manufacturing; 3, pottery clay selection; 4, slurry preparation; 5, slurry injection; 6, shaping;7, bisque firing; 8, glazing; and 9, firing. In step 3, pottery clay used for manufacturing a blank is selected and is high-aluminum clay, wherein 5%-10% of aluminum and 5%-10% of silicon are added into the high-aluminum clay.

Owner:ZHENGZHOU JIAYIBEI PACKAGING DESIGN CO LTD

Production method for Jun porcelain handicraft product having Chinese bottle model

InactiveCN109249742AEmbody design thinkingDecorative surface effectsSpecial ornamental structuresSlurryEngineering

The invention relates to a production method for a Jun porcelain handicraft product having a Chinese bottle model, and belongs to the field of Jun porcelain handicraft products. The production methodcomprises: 1, carving models; 2, making molds; 3, selecting pot clay; 4, pulping; 5, grouting; 6, patching; 7, carrying out biscuit firing; 8, glazing; and 9, firing, wherein the step 4 pulping comprises: carrying out mixing crushing on the pot clay selected in the step 3 to achieve a crushed particle size of 200-300 mesh, adding water, stirring, and filtering to prepare a billet slurry.

Owner:许昌市金堂钧瓷文化发展有限公司

Multifunctional minitype molecular motion demonstration instrument

InactiveCN103150948BExpand the experimental operation surfaceExperimental dosage is smallEducational modelsChemical solutionEngineering

The invention relates to a multifunctional minitype molecular motion demonstration instrument which is a sealed transparent box body, wherein a drawing partition plate is arranged in the middle of the box body so that the box body is divided into a left cavity and a right cavity which are not communicated with each other; openings at left and right sides of the box body are respectively provided with a first choke plug which plays a role in sealing, and a suspension component is arranged at the inner side of the top wall of each cavity in a length direction; and a plurality of pieces of linearly-arranged test paper are hung on each suspension component, and a chemical solution dripping hole is formed on the top wall of each cavity and is sealed through a second choke plug. A gas molecular motion experiment and a liquid particle motion experiment can be conveniently and rapidly demonstrated in the demonstration instrument, and the two experiments are not influenced by each other. The demonstration instrument has the advantages of good demonstration effect, low experiment reagent dose and excellent promotional value.

Owner:刘畅

Manufacturing method of jun porcelain artware with dragon seal shape

InactiveCN109017114AEmbody design thinkingDecorative surface effectsSpecial ornamental structuresMaterials scienceSlurry

The invention relates to a manufacturing method of a jun porcelain artware with a dragon seal shape, and belongs to the field of jun porcelain artwares. The manufacturing method of the jun porcelain artware in the dragon seal shape comprises the following steps of (1) sculpturing a model; (2) manufacturing a mold; (3) selecting pottery clay; (4) pulping; (5) grouting; (6) shaping; (7) biscuiting;(8) glazing; and (9) firing. According to the step 5, a blank slurry smelted in the step 4 is grouted into the mold manufactured by the step 2, a blank is manufactured in a layer-by-layer stacking way, and the thickness of the blank is ensured to range from 35 to 45mm.

Owner:禹州市元丰钧陶瓷有限公司

Production method for Jun porcelain handicraft product having Chinese bottle model

InactiveCN109249743AEmbody design thinkingDecorative surface effectsSpecial ornamental structuresEngineeringBottle

The invention relates to a production method for a Jun porcelain handicraft product having a Chinese bottle model, and belongs to the field of Jun porcelain handicraft products. The production methodcomprises: 1, carving models; 2, making molds; 3, selecting pot clay; 4, pulping; 5, grouting; 6, patching; 7, carrying out biscuit firing; 8, glazing; and 9, firing, wherein the step 8 glazing comprises: respectively glazing the biscuit-fired ball body billet, the biscuit-fired bottle lug billet and the biscuit-fired rhomboid body billet obtained in the step 7, and the glazing method is dip glazing.

Owner:许昌市金堂钧瓷文化发展有限公司

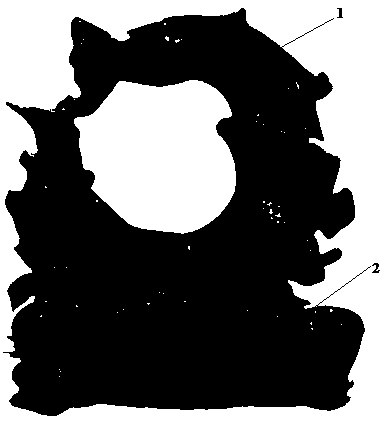

Method for manufacturing Jun porcelain handicraft article with dragon head shape

InactiveCN109227883AEmbody design thinkingDecorative surface effectsSpecial ornamental structuresHead shapeMaterials science

The invention relates to a method for manufacturing a Jun porcelain handicraft article with a dragon head shape, and belongs to the field of Jun porcelain handicraft articles. The method comprises thefollowing steps: 1, engraving a model, 2, manufacturing a mold; 3, selecting pottery clay; (4) pulping (5) grouting 6, trimming; (7) biscuiting 8, glazing; (9) firing, wherein step 8 is glazing a dragon of an intact blank fired in step 7; the glazing method comprises glazing by dipping, the dragon is dipped into glaze.

Owner:禹州市元丰钧陶瓷有限公司

Making method of Jun porcelain artware of Chinese bottle shape

InactiveCN109130672AEmbody design thinkingDecorative surface effectsSpecial ornamental structuresSlurryBottle

The invention discloses a making method of Jun porcelain artware of a Chinese bottle shape and belongs to the field of Jun porcelain artware. The making method comprises the following steps: 1, engraving a model; 2, making a mold; 3, selecting pottery clay; 4, making slurry; 5, carrying out slurry casting; 6, shaping; 7, biscuiting; 8, glazing; 9, firing, wherein the temperature in the firing process in the step 9 is slowly increased at a primary stage, the temperature is kept when being increased to 750 DEG C, and firing lasts for 4.5 hours.

Owner:许昌市金堂钧瓷文化发展有限公司

Production method of jun porcelain art craft with modeling of horse stepping on flying swallow

InactiveCN107586114AEmbody design thinkingOrnamental structuresSpecial ornamental structuresPotassiumSlurry

The invention discloses a production method of a jun porcelain art craft with a modeling of horse stepping on flying swallow and belongs to the field of jun porcelain art crafts. The production methodis characterized by comprising the following steps: firstly, carving a model; secondly, producing a mould; thirdly, selecting clay; fourthly, preparing slurry; fifthly, injecting the slurry; sixthly,patching; seventhly, biscuiting; eighthly, glazing; ninthly, firing; in the eighth step, the color of a first horse is furnace jun gold spot glaze, namely the color similar to ancient bronze ware, wherein the glaze is prepared from 0 percent of melilite, 20 percent of local feldspar from Yuzhou, Henan, China, 5 percent of talcum, 6 percent of red feldspar, 5 percent of zinc oxide, 10 percent of potassium feldspar, 3 percent of malachite, 0.5 percent of stannic oxide, not greater than 2 percent of copper and 20 percent of plant ash. The production method has the characteristic that jun porcelain is adopted to embody the style of unearthed ancient bronze ware.

Owner:YUZHOU ZHENGYUJUN KILN CO LTD

Manufacturing method of jun-porcelain artware of dragon-holding-head mould

The invention discloses a manufacturing method of jun-porcelain artware of dragon-holding-head mould, and belongs to the field of the jun-porcelain artware. The method comprises the following steps: 1, carving a mould; 2, manufacturing a mold; 3, selecting pottery clay; 4, pulping; 5, grouting; 6, mould truing; 7, biscuiting; 8, glazing; 9, burning. The step 7 comprises the following operations ofplacing the trued parisons of horse and swallow in a biscuiting kiln to perform biscuiting, burning for 4.5-6 hours at the temperature of 970-1000 DEG C, naturally cooling for 10 hours after ceasingfire. The manufacturing method has the features of maintaining the parison stability and reducing the middle damage.

Owner:禹州市元丰钧陶瓷有限公司

Manufacturing method of Jun porcelain artware with rooster shape

The invention discloses a manufacturing method of Jun porcelain artware with a rooster shape, and belongs to the field of the Jun porcelain artware. The manufacturing method comprises the steps of (1)model carving, (2) mold manufacturing, (3) argil selection, (4) pulping, (5) pulp injection, (6) shaping, (7) biscuiting, (8) glazing and (9) firing; and in the step (7), blanks of a rooster and a base finished in the step (6) are put in a biscuiting kiln for biscuiting, are fired by 4.5-6 hours at a temperature of 970-1000 DEG C, and are stopped firing to naturally cool by 10 hours. The manufacturing method has the characteristics of capability of maintaining stable blanks and reduction of middle loss.

Owner:YUZHOU ZHENGYUJUN KILN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com