Hopper conveying machine

A conveyor and hopper technology, applied in the field of packaging machinery, can solve the problems of inability to accommodate multiple metering devices, difficult metering and conveying, etc., and achieve the effects of convenient installation and adjustment, reliable performance, compact and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

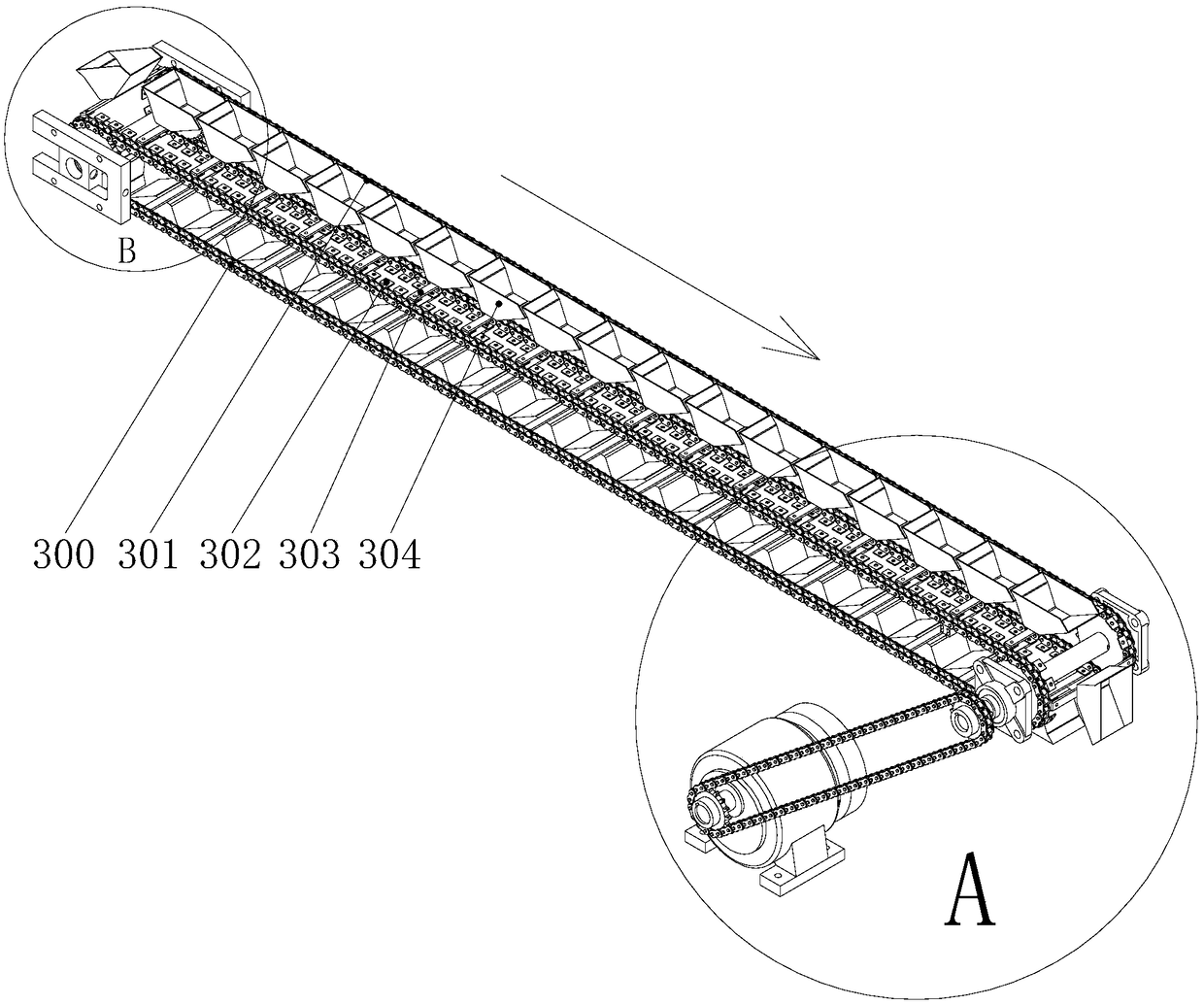

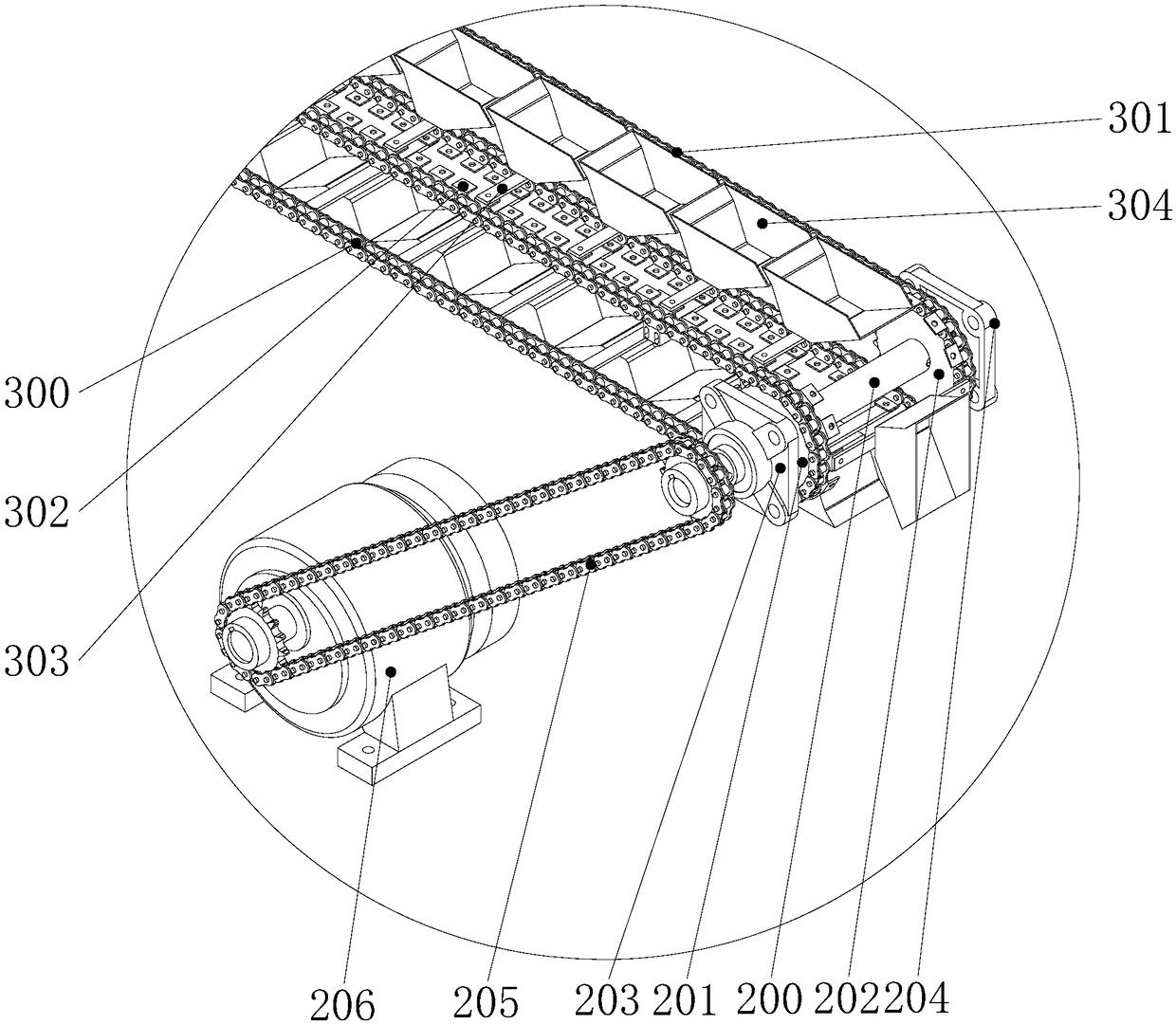

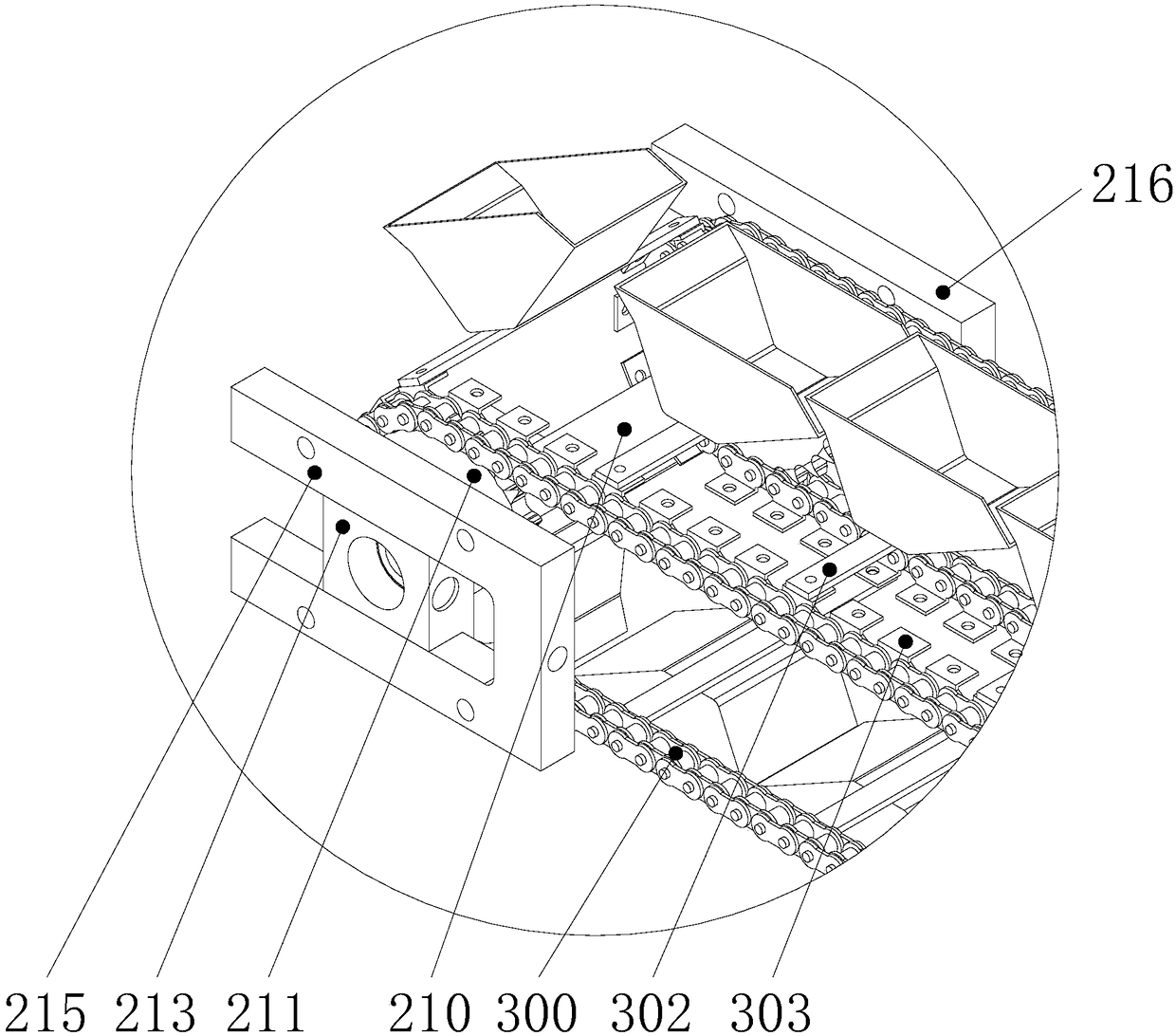

[0025] As shown in the accompanying drawings, the present invention provides a hopper conveyor, including a transmission mechanism, several hoppers, a power transmission mechanism and a support platform. Seat 204 is installed on the front end of inner U-shaped steel 102, and driving shaft 200 is connected in outer bearing seat 203 and inner bearing seat 204 through bearings, and outer driving gear 201 and inner driving gear 202 are installed on driving shaft 200 respectively; Outer tension frame 215 Installed on the rear end of the outer U-shaped steel 101, the inner tension frame 216 is installed on the rear end of the inner U-shaped steel 102, and the two ends of the driven shaft 210 are connected to the outer driven bearing seat 213 and the inner driven bearing seat 214 through bearings. The driven bearing seat 213 and the inner driven bearing seat 214 are re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com