Thread breaking stopping device of plastic circular weaving machine

A technology of stopping device and circular loom, which is applied to circular looms, looms, textiles, etc., can solve the problems of low efficiency, low sensitivity of conductive rods, and inability to form partition management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

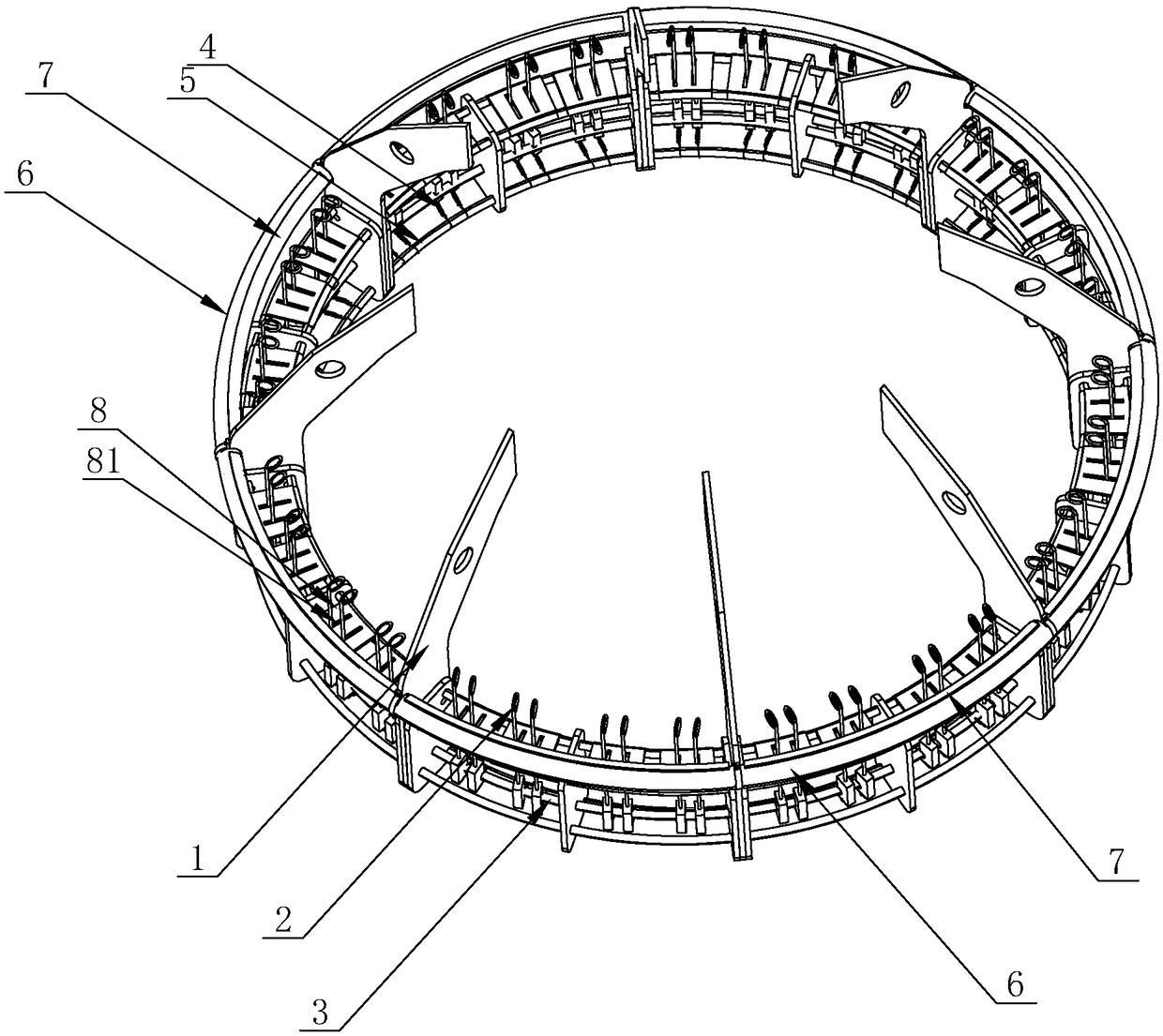

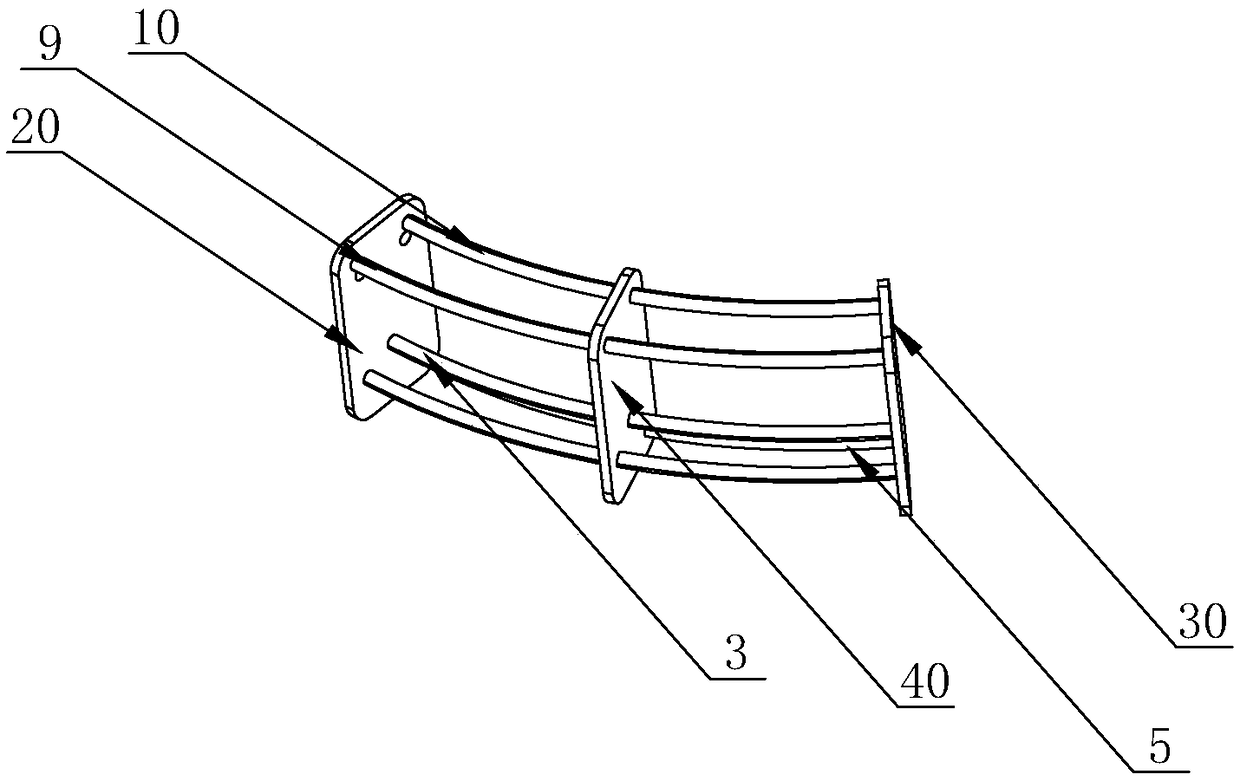

[0016] like Figure 1-2 As shown, a thread-breaking stop device for a plastic circular loom includes an archway 1, several archways 1 are arranged at intervals in a circle, and a jumper 2, a jumper pole 3, Spring 4, spring pole 5, jumper 2 are set on the jumper pole 3, jumper 2 can rotate around the jumper pole 3, one end of spring 4 is connected with the lower end of jumper 2, and the other end is connected with spring pole 5 Connection, the outer side of the jumping pole 2 is provided with an annular insulating support rod 6, and the archway 1 is fixedly connected with the insulating support rod 6. Of course, the insulating support rod 6 can also be fixed with the frame of the circular loom. As for the fixing method, bolts, etc. can be used. Fasteners are fixed, or other methods such as welding and buckling are realized. The insulating support rod 6 can be made of insulating materials such as wood and plastics. The conductive film 7 contacted by the rod 2 can be purchased d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com