Furred ceiling edge closing method with combined structure, and combined furred ceiling edge closing section bar assembly

A duplex ceiling and composite technology, which is applied to building structures, ceilings, building components, etc., can solve problems such as inconvenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

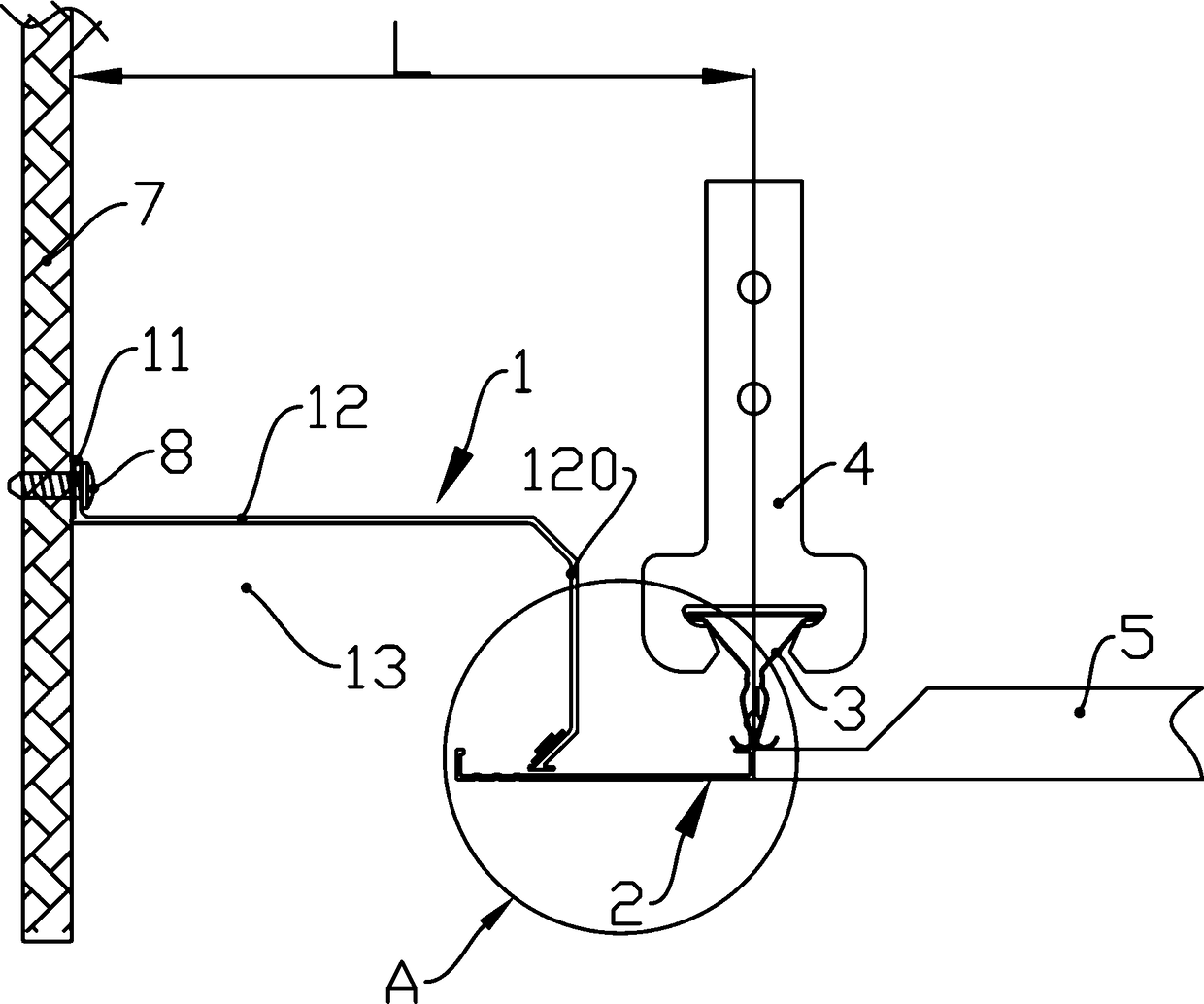

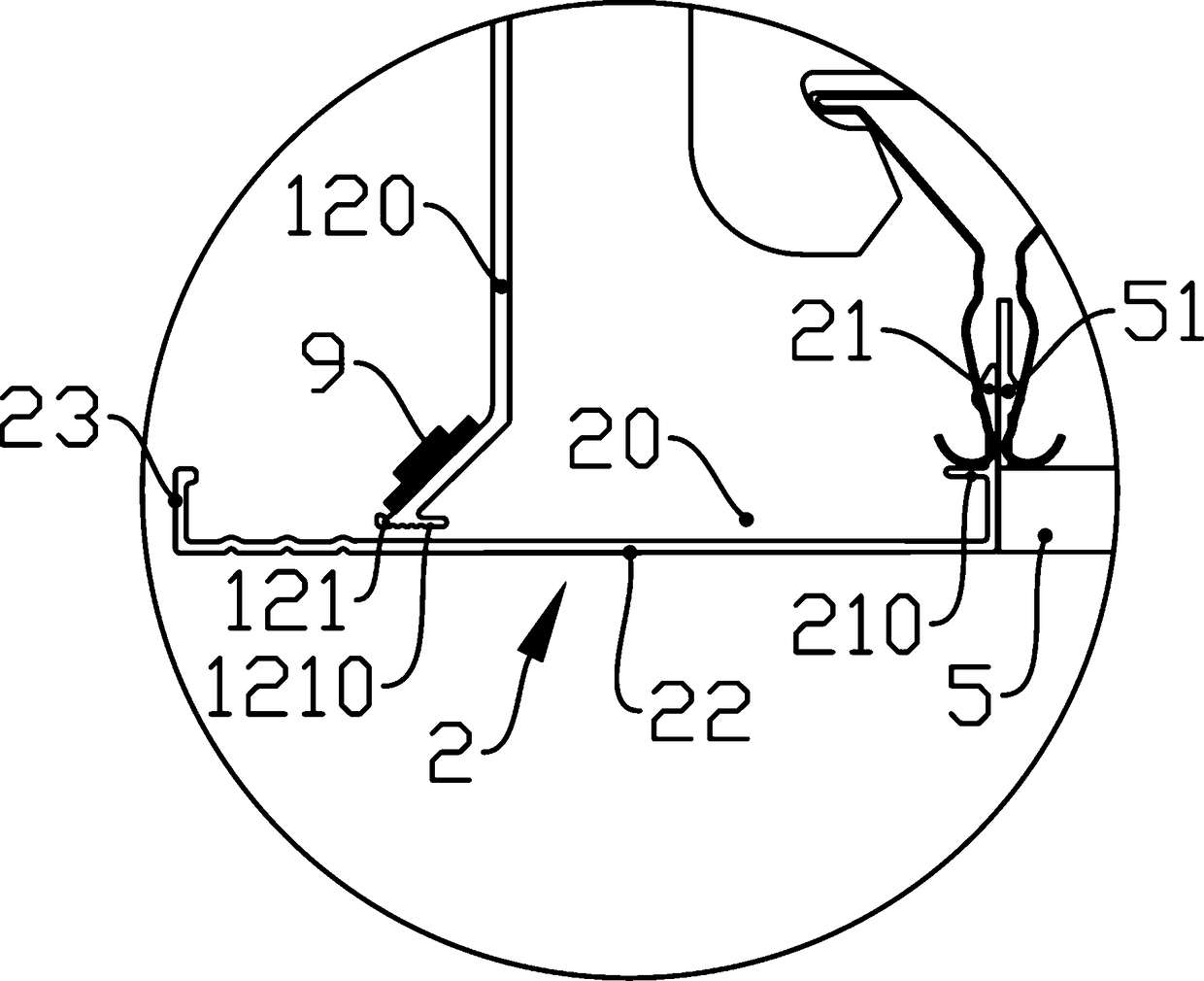

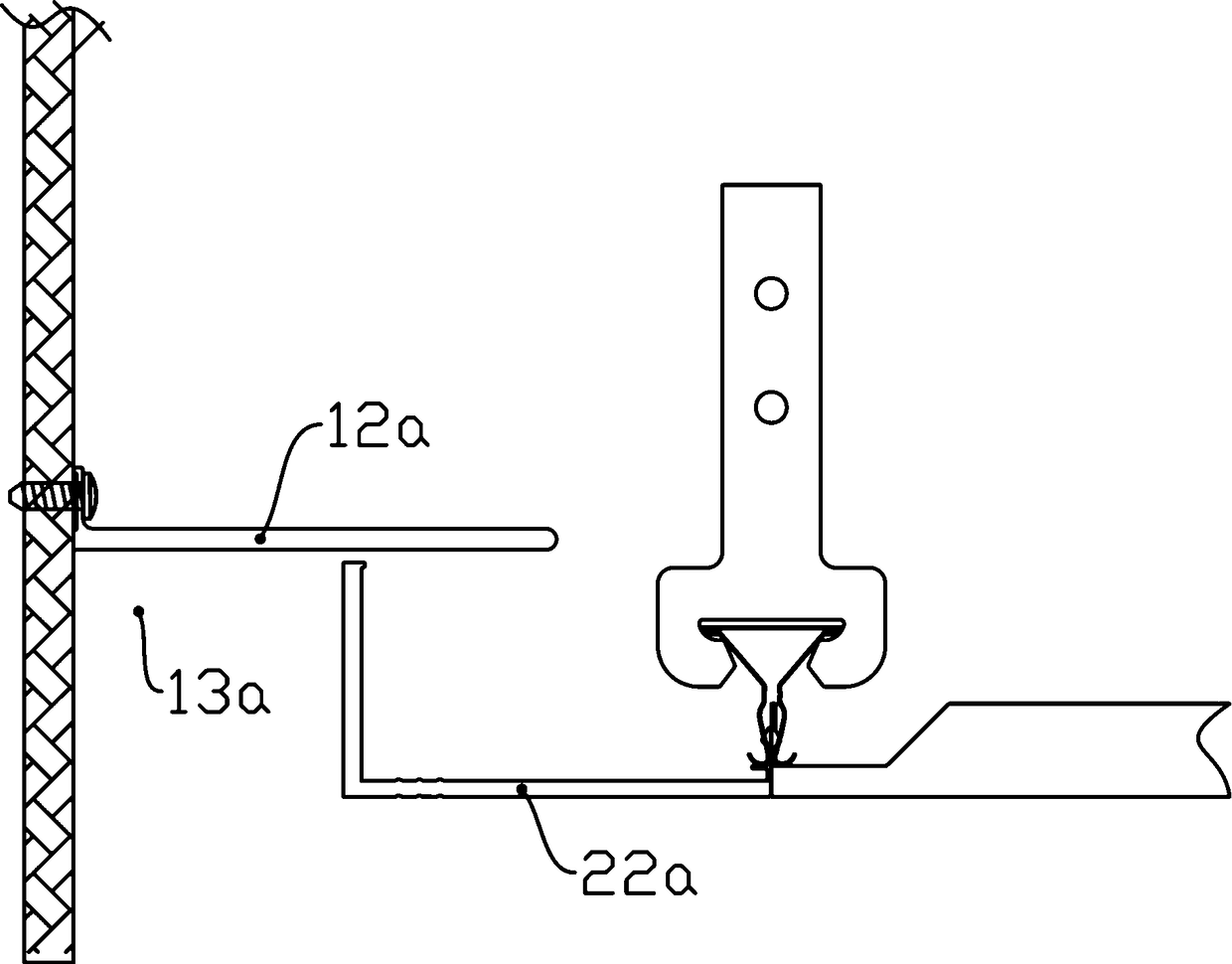

[0031] Below in conjunction with the accompanying drawings, a further description will be made on the structure of the ceiling trimming method and the ceiling trimming profile assembly in a compound structure applying the technical solution of the present invention.

[0032] Such as figure 1 with figure 2 As shown, the compound ceiling edge trimming profile assembly includes a first edge trimming profile 1 and a second edge trimming profile 2 that are separated left and right and can overlap or approach each other. The first edge trimming profile 1 has a positioning portion 11 that can be fixedly connected to the positioning base 7 and a first decorative portion 12 that can constitute a first ceiling decoration layer; the second edge trimming profile 2 has a positioning portion that can be vertically The vertical inserting arm 21 inserted from bottom to top on the ceiling keel 3 and the second horizontal decorative part 22 that can constitute the second suspended ceiling dec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com