An adjustable downhole supercritical carbon dioxide jet sand mixing device

A technology of carbon dioxide and jet flow device, which is applied in the direction of mining fluid, wellbore/well components, earthwork drilling and production, etc. It can solve the problems of inability to control sand concentration in real time, low viscosity characteristics, poor sand-carrying ability, etc., so as to facilitate the lifting and lowering of pipe Column and device, simple operation, and simplified equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings.

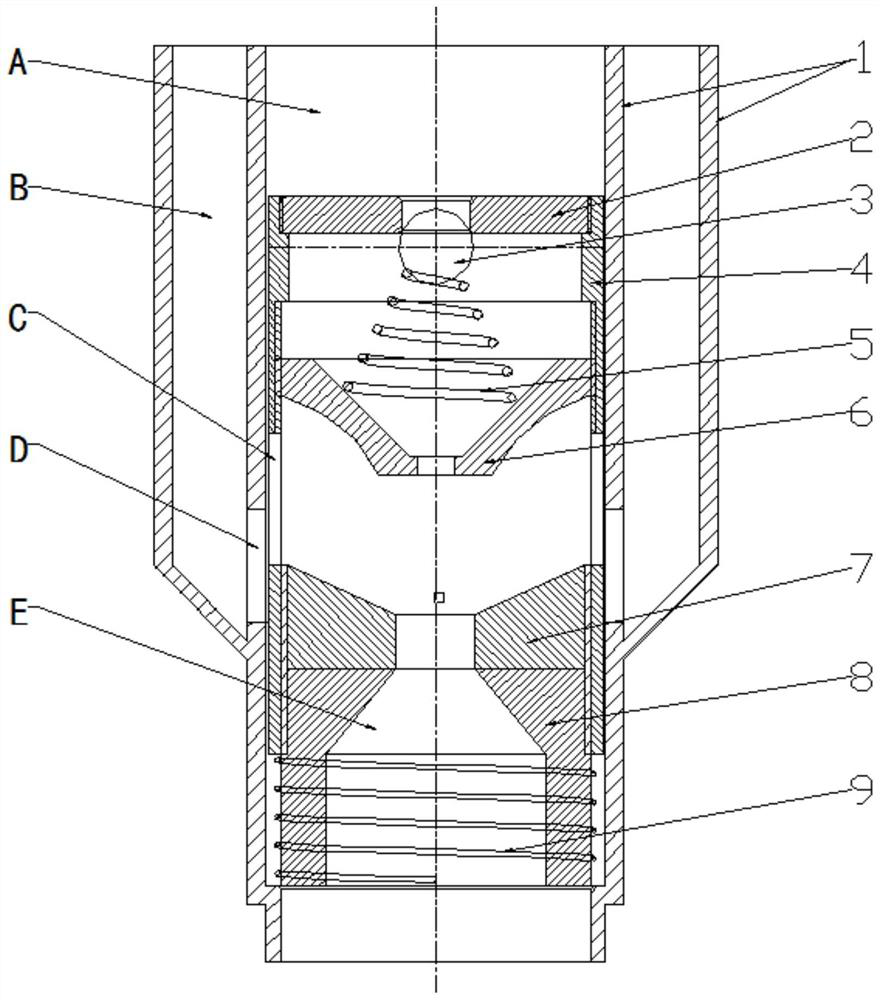

[0014] refer to figure 1 , an adjustable downhole supercritical carbon dioxide jet sand mixing device, comprising a sand conveying pipe 1 which is threadedly connected with a concentric pipe string in a wellbore, and a jet device 4 is arranged inside the sand conveying pipe 1 .

[0015] The smaller diameter part of the sand delivery pipe 1 is the inner pipe, and the larger diameter part is the outer pipe. The sand chamber is between the inner and outer pipe walls. There are 2-4 sand pipes evenly distributed circumferentially in the lower part of the sand delivery pipe 1. Two suction port D;

[0016] The uppermost part of the jet device 4 is a valve cover 2, and a through hole is opened on the valve cover 2, and the valve ball 3 is located below the through hole, and the valve ball 3 is installed on the first spring 5 below, and the nozzle is below the first spring 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com