Filter and engine assembly

A filter and filter tank technology, which is applied in the installation/connection of lubricant purification devices, lubricating parts, pressure lubricants, etc., can solve the problems of easy oil flow, wear, and lack of oil in moving parts, so as to prevent wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

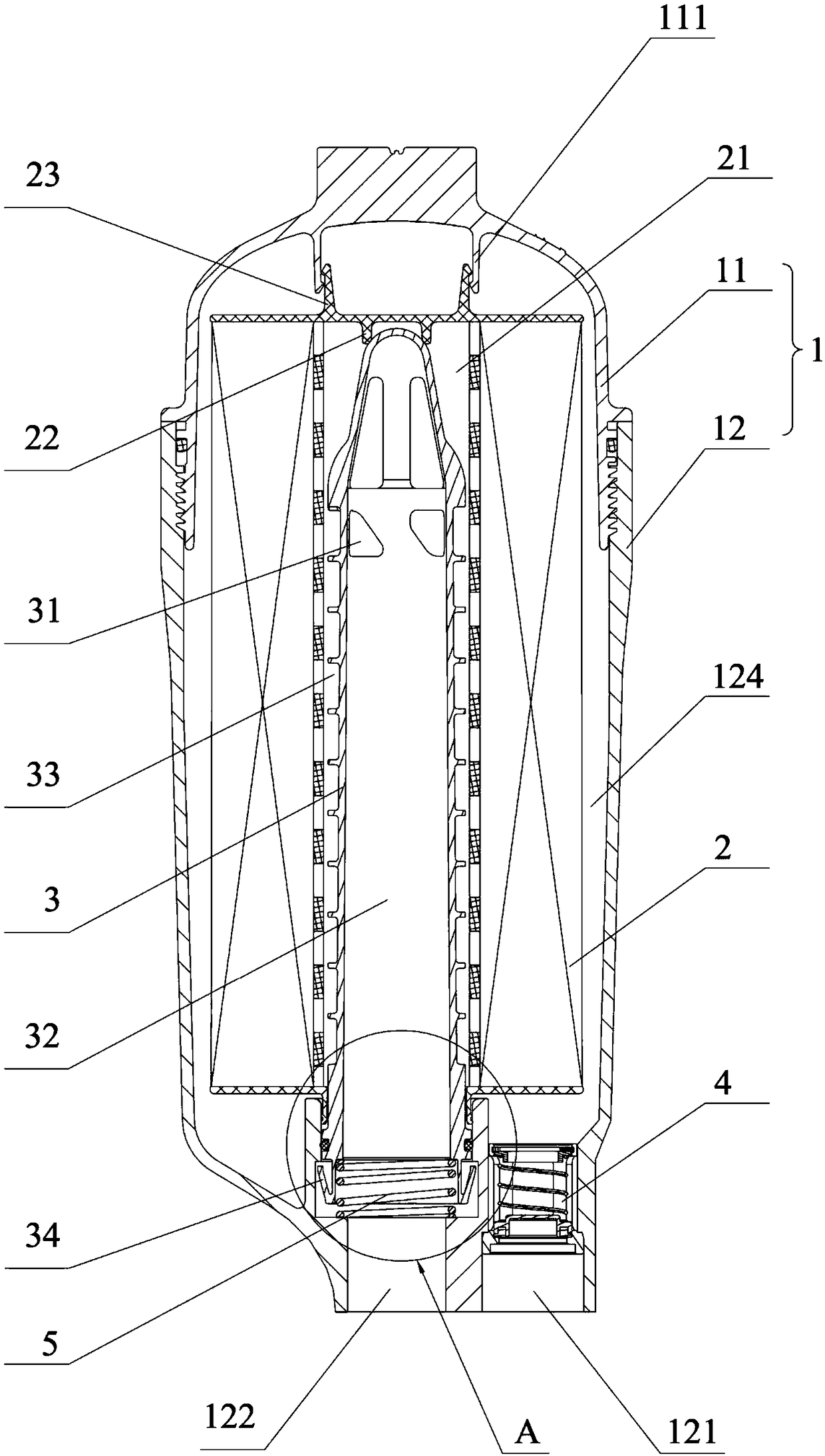

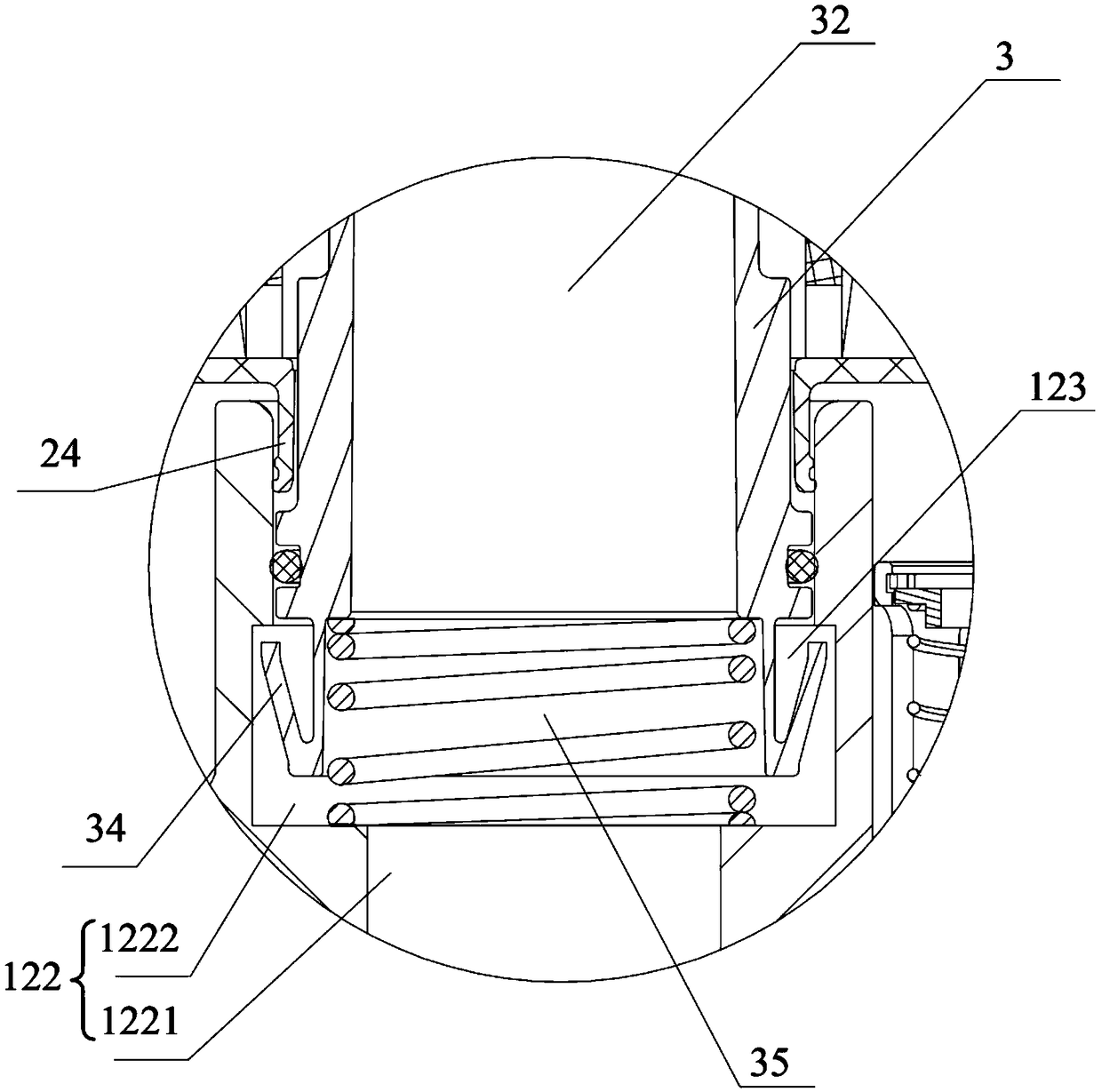

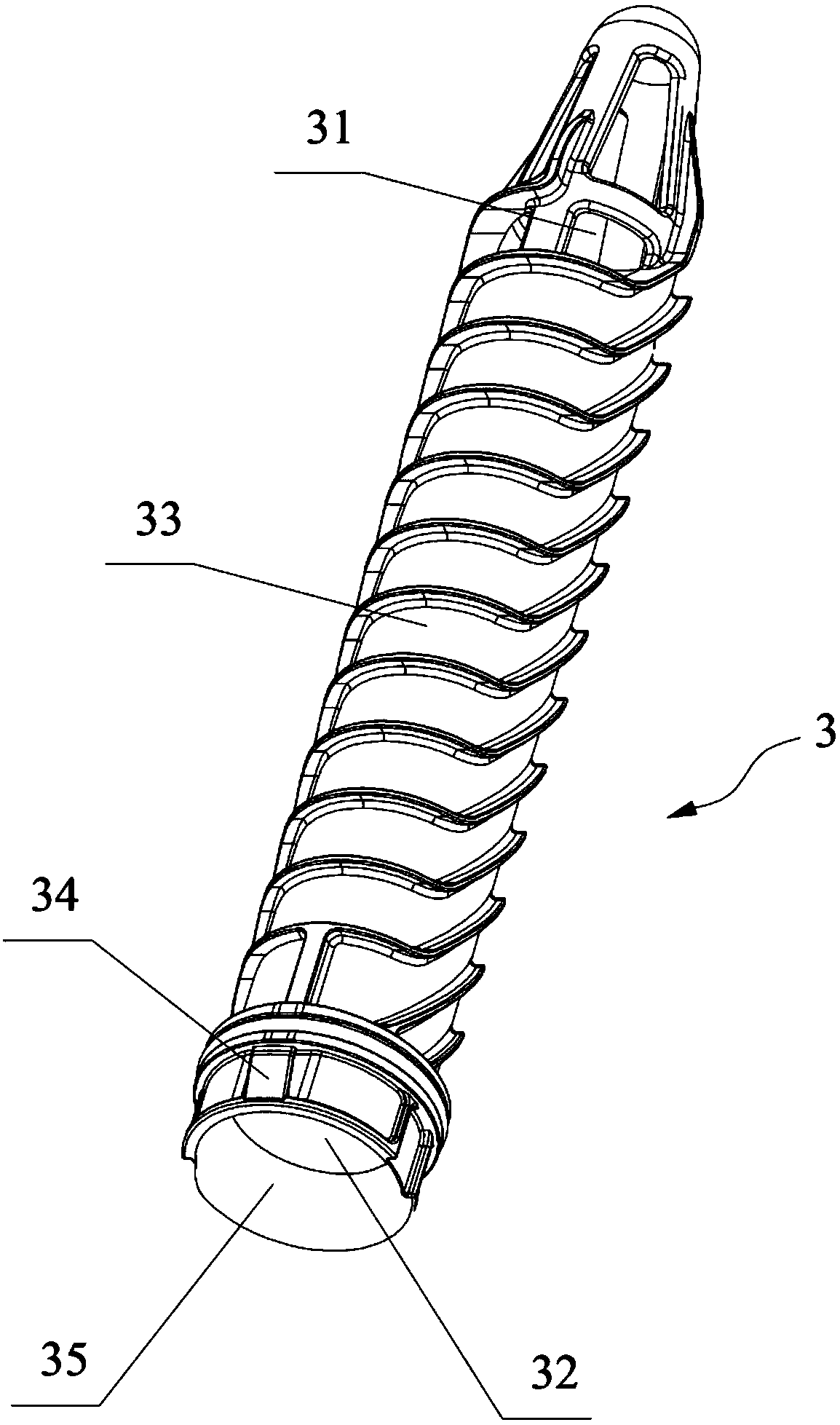

[0037] Such as Figure 1~3 As shown, the present embodiment provides a filter, which includes a filter tank 1, a filter element 2, a middle pipe 3 and a first one-way valve 4, the inside of the filter tank 1 is provided with a filter cavity 124, and the filter tank 1 is provided with an oil inlet 121 and an oil outlet 122 communicating with the filter cavity 124, the oil outlet 122 is connected with the main oil passage, the first check valve 4 is installed at the oil inlet 121, the oil inlet 121 is connected with the oil The pan is communicated with the pipeline, and the engine oil can enter the filter cavity 124 from the oil pan through the first one-way valve 4, so that after the engine stops, the engine oil in the filter cavity 124 will not flow back to the oil pan through the oil inlet 121 mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com