Oil supply system for valve clearance-equalizing hydraulic tappets

A technology of oil supply system and hydraulic tappet, which is applied in the direction of valve device, engine components, machine/engine, etc., and can solve the problem of oil passage emptying and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

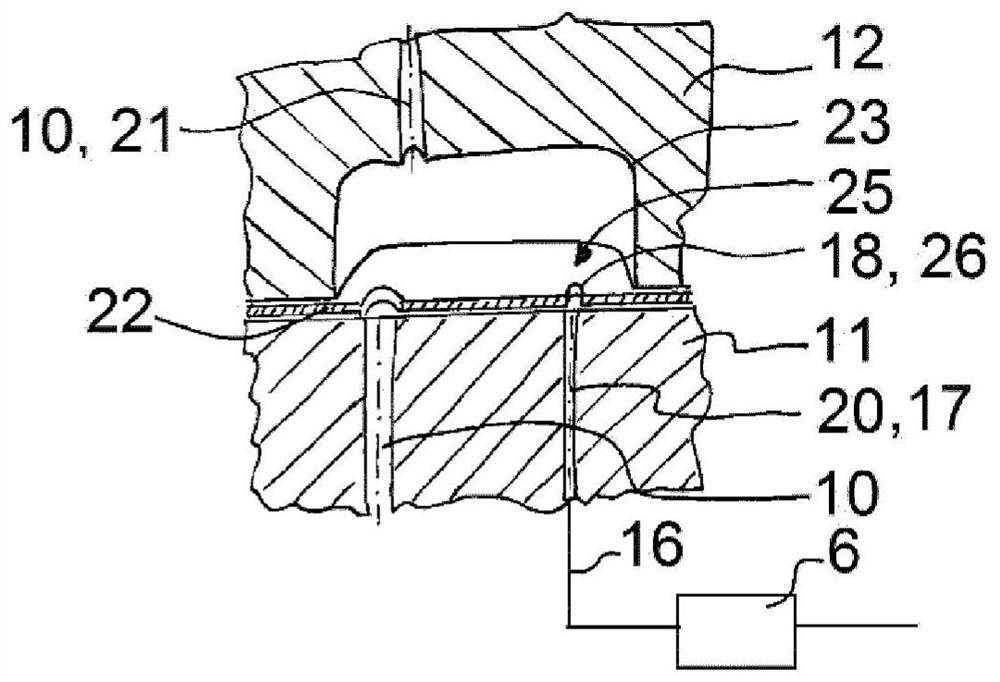

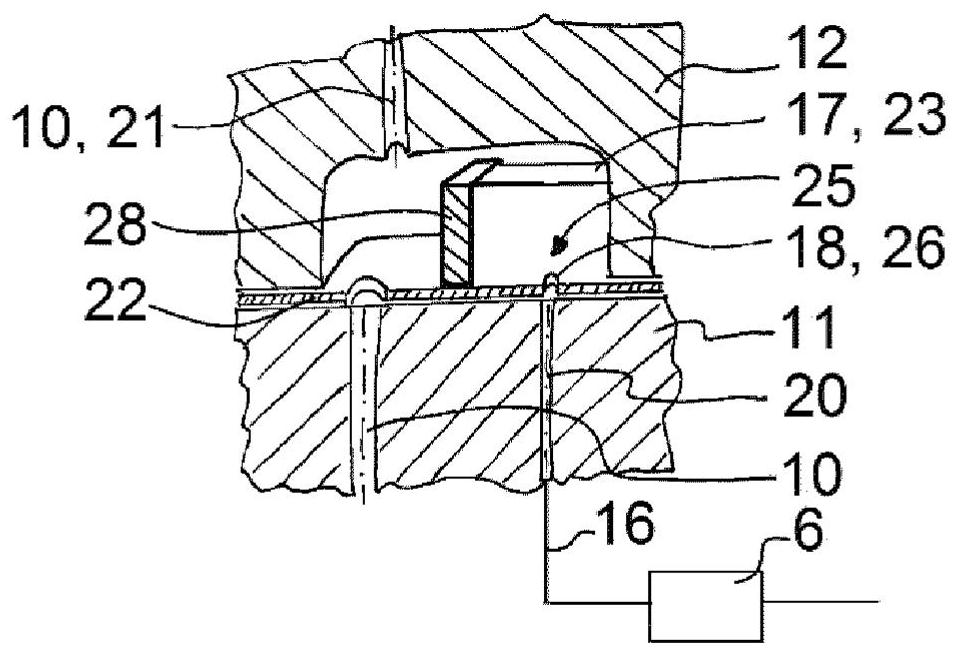

[0033] The description that follows is merely illustrative in nature. For purposes of clarity, the same reference numbers have been used in the drawings to refer to similar elements. The supply lines can be realized via boreholes in the component or via pipes connected thereto.

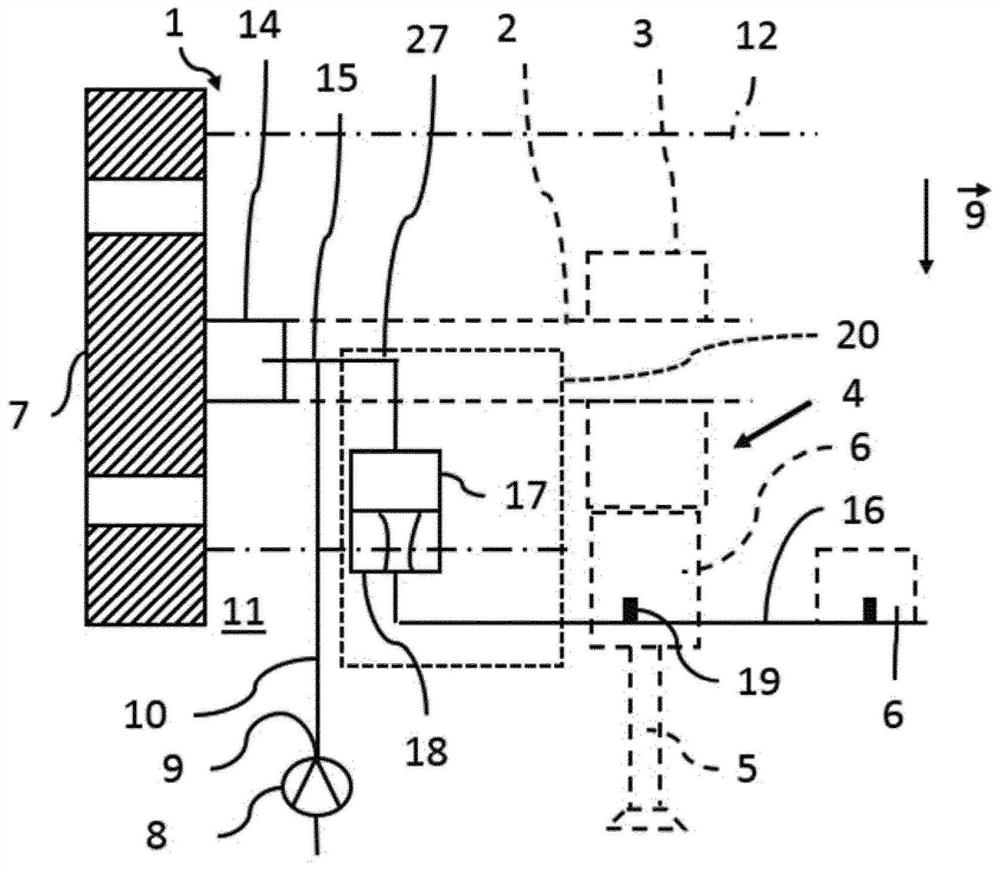

[0034] figure 1 An oil supply system 1 for supplying oil to a camshaft 2 is shown. Some components, such as the cam 3 , which actuates the valve 5 via the load path 4 , require oil as coolant and lubricant. The valve 5 can be an inlet valve or an outlet valve of an internal combustion engine not shown otherwise. A hydraulic tappet 6 is located in the load path 4 . The hydraulic tappet 6 is filled with oil in order to compensate possible play in the load path 4 .

[0035] Oil is delivered to outlet 9 by oil pump 8 . The outlet 9 is connected in a flow-conducting manner to a first supply line 10 . In the ready-to-operate installation position of the internal combustion engine, the first supply li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com