Novel anti-freezing valve

A valve and a new type of technology, applied in thermal insulation, pipes/pipe joints/fittings, heat exchange equipment, etc., can solve the problems of easy freezing of valves, frozen valves, poor thermal insulation effect, etc., to achieve good thermal insulation effect and comprehensive thermal insulation methods. , good insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further elaborated below in conjunction with accompanying drawing and specific embodiment:

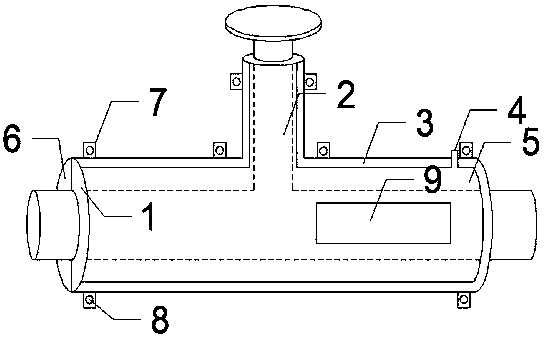

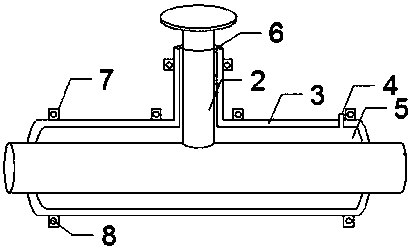

[0010] As shown in the figure, a new antifreeze valve includes a first half shell 1, a second half shell 6, a valve 2, and an air nozzle 4, and the first half shell 1 and the second half shell 6 have the same structure, Wherein the first half-shell 1 comprises a first thermal insulation layer 3, a second thermal insulation layer 5, a fixing block 7, a threaded hole 8, and a label 9, and it is characterized in that: the housing 1 is respectively provided with a first thermal insulation layer from the outside to the inside. Layer 3 and the second insulation layer 5, and the outer surface of the shell 1 is provided with a label 9, the fixed block 7 is welded on the first half shell 1 and the second half shell 6, and the center of the fixed block 7 is provided with a screw thread hole 8, the valve 2 is wrapped in the second insulation layer 5.

[0011]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com