A multipurpose fiber optic sensor

A fiber optic sensor and multi-purpose technology, which is applied in the direction of transmitting sensing components with optical devices, can solve the problems of variable frequency, difficulty in filtering, and influence of signal phase-frequency characteristics, etc., and achieves small phase detection error and application Wide range of occasions and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

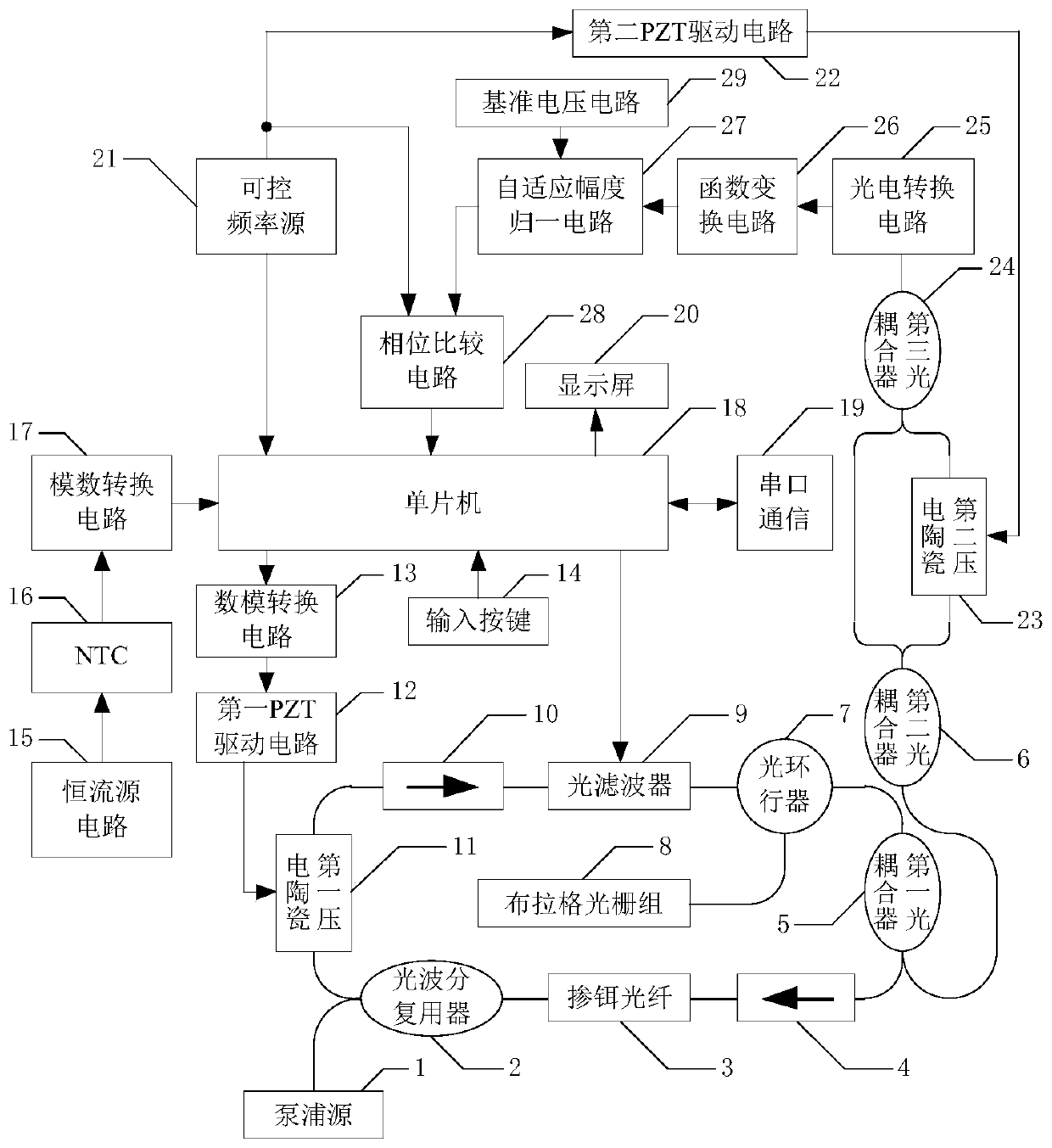

[0028] Embodiment 1 Overall structure of the present invention

[0029] Such as figure 1 As shown, the overall structure of the present invention has, the pump source 1 (980nm laser, maximum output power is 1W) is connected with the 980nm end of the optical wavelength division multiplexer 2 (980 / 1550nm wavelength division multiplexer), and the optical wavelength division multiplexer The 1550nm end of device 2 is connected with one end of the optical fiber wound on the first piezoelectric ceramic 11 (cylindrical piezoelectric ceramic, outer diameter 50mm, inner diameter 40mm, height 50mm), and the optical fiber wound on the first piezoelectric ceramic 11 The other end of the first optical isolator 10 (1550nm polarization-independent optical isolator) is connected to the input end, and the control end of the first piezoelectric ceramic 11 is connected to the first PZT drive circuit 12 (the device made by this research group, the specific structure is shown in The output port of...

Embodiment 2

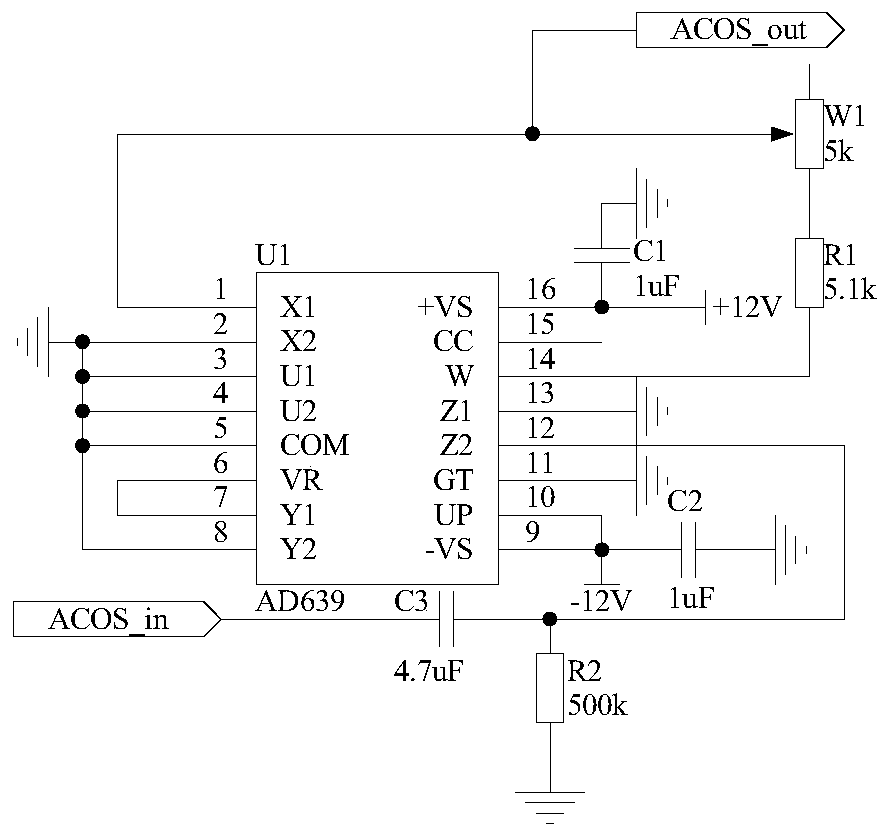

[0031] Embodiment 2 function conversion circuit

[0032] Such as figure 2As shown, the structure of the function conversion circuit 26 used in the present invention is that one end of the capacitor C3 is connected to the pin 12 of the trigonometric function converter U1 and one end of the resistor R2, and the other end of the capacitor C3 is used as the input end of the function conversion circuit 26 , recorded as the port ACOS_in, connected to the output end of the photoelectric conversion circuit 25; the other end of the resistor R2 is grounded; the pins 2, 3, 4, 5, 8, 11, and 13 of the trigonometric function converter U1 are grounded, and the pins 9, 10 is connected to one end of capacitor C2 and -12V power supply, and the other end of capacitor C2 is grounded; pin 6 of trigonometric function converter U1 is connected to pin 7, pin 16 is connected to +12V power supply and one end of capacitor C1, capacitor C1 The other end of the trigonometric function converter U1 is con...

Embodiment 3

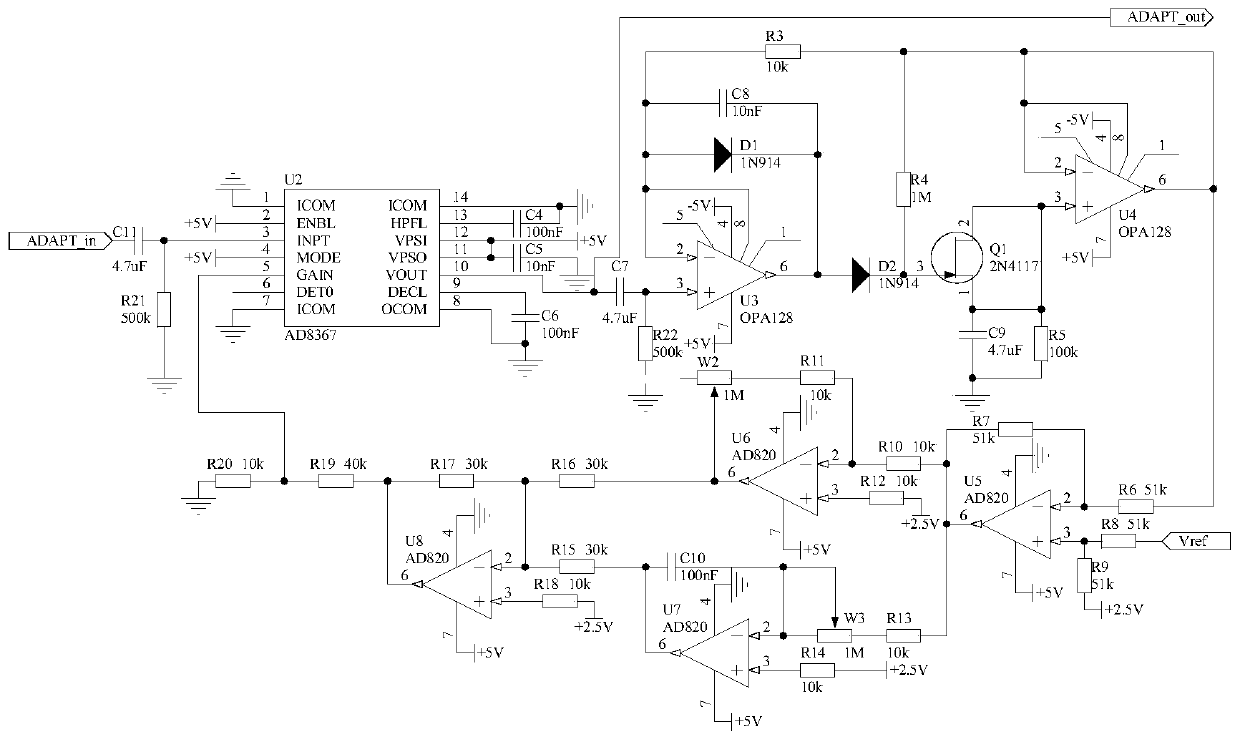

[0033] Embodiment 3 Adaptive Amplitude Normalization Circuit

[0034] Because the signal amplitude of the function conversion circuit 26 output is relatively small, and is affected by multiple parameters in the optical path and the circuit, the size is indefinite, so the present invention has designed an adaptive amplitude normalization circuit 27, which is used for the signal output by the function conversion circuit 26 The amplitude is normalized to the optimal size to further improve the accuracy of demodulation. The specific structure is that one end of the capacitor C11 is connected to one end of the resistor R21 and the pin 3 of the chip U2, the other end of the resistor R21 is grounded, and the other end of the capacitor C11 is used as the input end of the adaptive amplitude normalization circuit 27, which is recorded as the port ADAPT_in , is connected with the port ACOS_out of the function conversion circuit 26; the pin 1, the pin 7, the pin 8 and the pin 14 of the ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com