Testing method for anti-fogging performance of lamp

A testing method and lamp technology, which is applied in the direction of optical instrument testing, machine/structural component testing, measuring devices, etc., can solve problems such as delayed product launch date and late test time, and achieve the effect of ensuring on-schedule listing and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

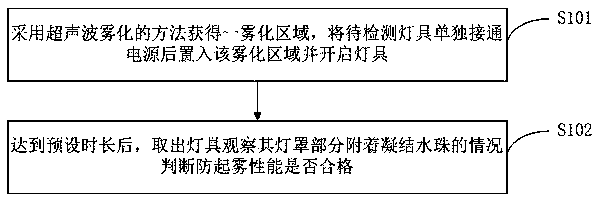

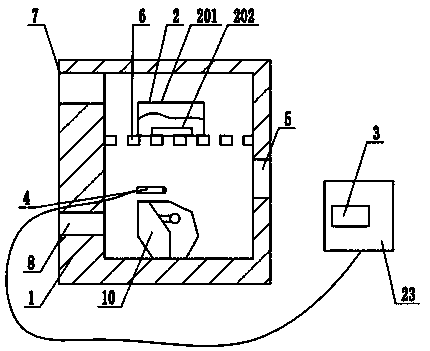

[0051] Such as figure 1 and figure 2 As shown, this application discloses a method for testing the anti-fogging performance of lamps. An ultrasonic atomization method is adopted to obtain an atomization area. After the lamp to be tested is individually powered on, the lamp is placed into the atomization area and the lamp is turned on to achieve the preset value. After setting the length of time, observe the condition of the condensation water on the lampshade to judge whether the anti-fogging performance is qualified.

[0052] The anti-fogging performance of the lamp to be tested in this application at a specific ambient temperature and humidity allows the lamp to be tested before assembly, which facilitates optimization and improvement of the lamp in advance, and ensures that the product is launched on time. In addition, this application can test the vehicle lights in high beam and low beam modes respectively. This application can first observe when the first preset time is rea...

Embodiment 2

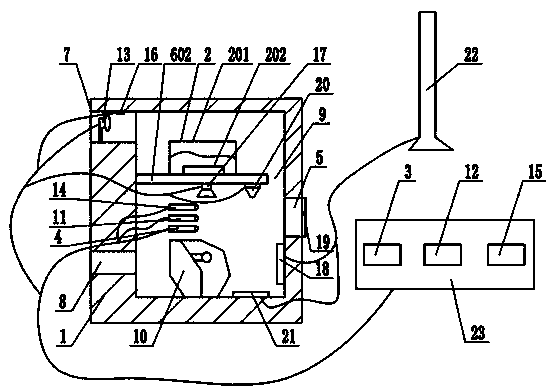

[0074] Such as figure 1 and image 3 As shown, this application discloses a method for testing the anti-fogging performance of lamps. An ultrasonic atomization method is adopted to obtain an atomization area. After the lamp to be tested is individually powered on, the lamp is placed into the atomization area and the lamp is turned on to achieve the preset value. After setting the length of time, observe the condition of the condensation water on the lampshade to judge whether the anti-fogging performance is qualified.

[0075] The anti-fogging performance of the lamp to be tested in this application at a specific ambient temperature and humidity allows the lamp to be tested before assembly, which facilitates optimization and improvement of the lamp in advance, and ensures that the product is launched on time. In addition, this application can test the vehicle lights in high beam and low beam modes respectively. This application can first observe when the first preset time is reac...

Embodiment 3

[0107] Such as figure 1 and Figure 4 As shown, this application discloses a method for testing the anti-fogging performance of lamps. An ultrasonic atomization method is adopted to obtain an atomization area. After the lamp to be tested is individually powered on, the lamp is placed into the atomization area and the lamp is turned on to achieve the preset value. After setting the length of time, observe the condition of the condensation water on the lampshade to judge whether the anti-fogging performance is qualified.

[0108] The anti-fogging performance of the lamp to be tested in this application at a specific ambient temperature and humidity allows the lamp to be tested before assembly, which facilitates optimization and improvement of the lamp in advance, and ensures that the product is launched on time. In addition, this application can test the vehicle lights in high beam and low beam modes respectively. This application can first observe when the first preset time is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com