Bulk solid material friction characteristic test fixture and sample filling method

A technology of friction characteristics and solid materials, applied in the field of testing and friction characteristics testing, can solve the problems of large test error, material overflow boundary effect, material inapplicability, etc., to improve the test accuracy, improve the rib form, and facilitate the filling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

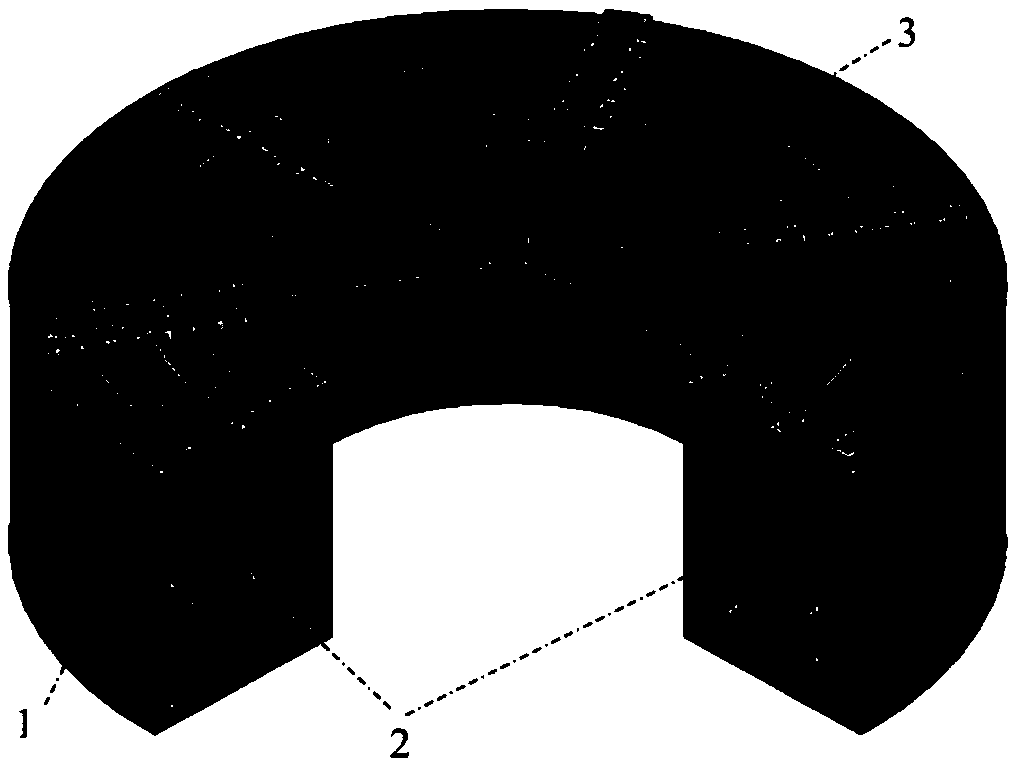

[0031] like figure 1 As shown, a fixture for testing the friction characteristics of bulk solid materials includes an outer ring 1, an inner ring 2, and a cover plate 3. When in use, the outer ring 1, the inner ring 2, and the cover plate 3 are coaxial, and the outer ring 1 and the inner ring 2 are coaxial. With relative rotation, the cover plate 3 cannot be displaced radially, but can move freely in the circumferential and axial directions.

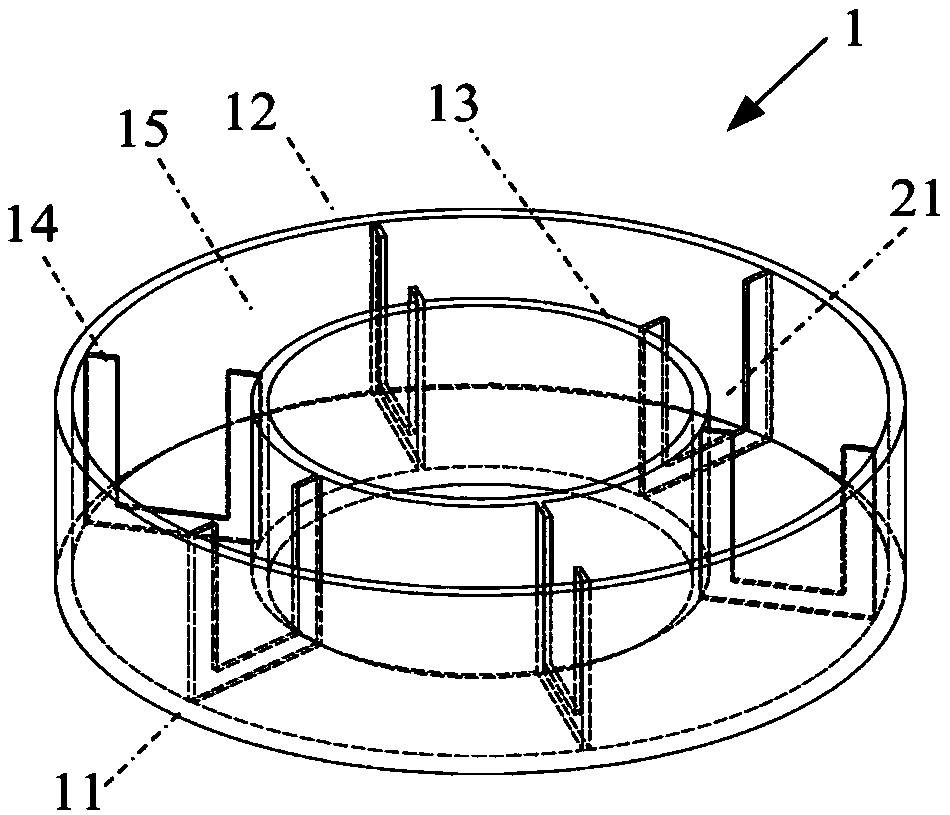

[0032] figure 2 It is a schematic diagram of the structure of the outer ring 1. The outer ring 1 is composed of a bottom plate 11, an outer wall 12, a ring core 13, an outer ring baffle 14 and a ring cavity 15; The plate 14 forms an annular cavity with three walls and one opening. The bottom plate 11, the outer wall 12, and the ring core 13 are provided with an outer ring baffle 14 near the side wall o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap