Preparation device and method of surface gradient scattering cladding optical power stripper

A technology for preparing devices and strippers, which is applied in the direction of instruments, light guides, optics, etc., and can solve the problems of reduced filtering power, cladding light leakage, and severe temperature rise on the device surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

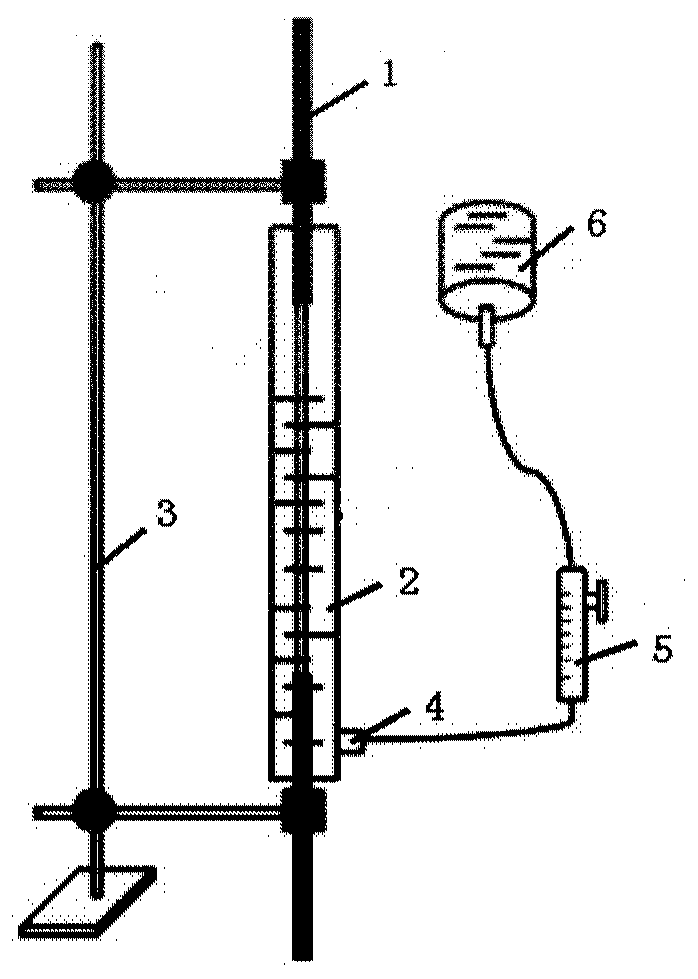

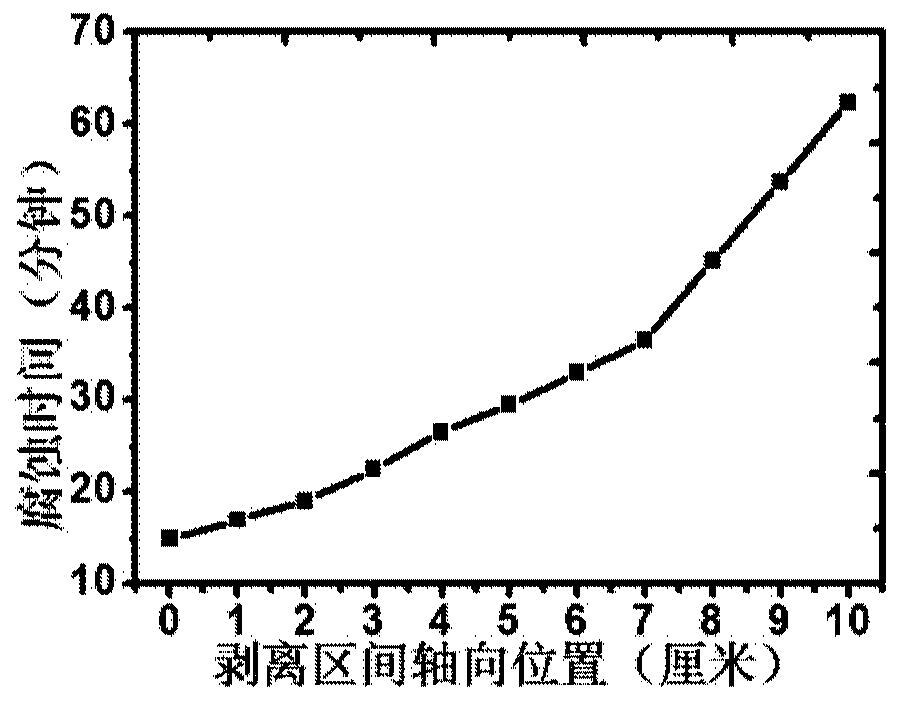

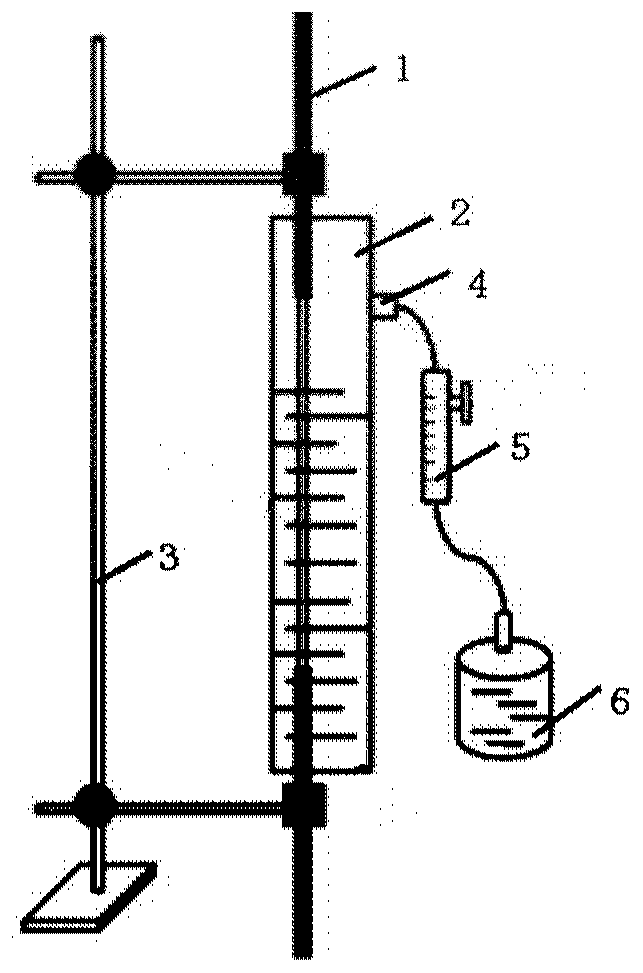

[0035] In the first exemplary embodiment of the present disclosure, a method for preparing a surface gradient scattering cladding optical power stripper is also provided. Figure 6 It is a flow chart of a method for preparing a surface gradient scattering cladding optical power stripper according to an embodiment of the present disclosure. Such as Figure 6 As shown, it includes: step A: peel off the coating layer of the middle section of the optical fiber to be corroded, and expose the bare fiber section; The cylinder is parallel and does not touch the reaction cylinder; step C: the container containing the corrosive solution is connected to the injection hole through the pipeline, and the corrosive solution is injected into the reaction cylinder; step D: the flow rate of the corrosive solution injected into the reaction cylinder is controlled by a flow meter, Control the rising speed of the corrosive liquid in the reaction cylinder, along the laser transmission direction, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com