Electron beam scanning drive control board and electron beam welding machine

A technology of electron beam scanning and drive control, applied in electron beam welding equipment, electrical program control, digital control, etc., can solve the problems of weak anti-interference ability and poor control drive signal accuracy, and achieve improved control accuracy and anti-interference. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

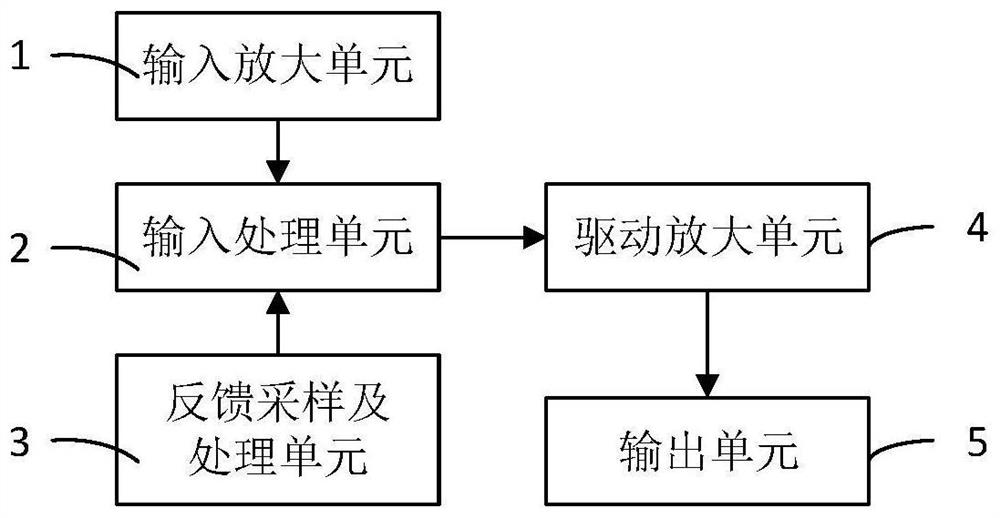

[0035] This embodiment provides an electron beam scanning drive control board for controlling the current of the scanning coil. Such as figure 1 As shown, the electron beam scanning drive control board includes an input amplification unit 1, a feedback sampling and processing unit 2, an input processing unit 3, a driving amplification unit 4 and an output unit 5, and the output terminal of the input amplification unit 1 and the feedback sampling and processing unit 2 The output end of the input processing unit 1 is electrically connected to the input end of the input processing unit 1, the output end of the input processing unit 3 is electrically connected to the input end of the driving amplifying unit 4, and the output end of the driving amplifying unit 4 is electrically connected to the input end of the output unit 5; wherein ,

[0036] The input amplification unit 1 is used to amplify the control input signal; the feedback sampling and processing unit 2 is used to obtain ...

Embodiment 2

[0052] This embodiment provides an electron beam welding machine. Such as Figure 8 and Figure 9 As shown, the electron beam welding machine includes an electron gun 81, an electron beam scanning coil 82, an electron beam scanning drive control board 83 and a signal generator 84. The electron gun 81 is used to emit electron beams, and the electron beam scanning coil 82 is arranged on the The emission path of the electron beam, the signal generator 84 is used to generate a control input signal for controlling the deflection direction of the electron beam, and the electron beam scanning drive control board 83 is used to process the control input signal, and the processed The driving signal is input into the electron beam scanning coil 82, wherein the electron beam scanning driving control board 83 adopts the electron beam scanning driving control board provided in Embodiment 1.

[0053] In this embodiment, the electron beam scanning coil 82 includes an X scanning coil and a Y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com