A micro-component operating device and method for four-needle integrated condensation compliance control

A compliant control and operating device technology, applied in micro manipulators, manufacturing tools, chucks, etc., can solve the problems of difficult direct application, difficult to realize real-time control of liquid media, single pick-up or release process, etc., to ensure stable acquisition and easy digitization Intelligent control, avoid the effect of borrowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

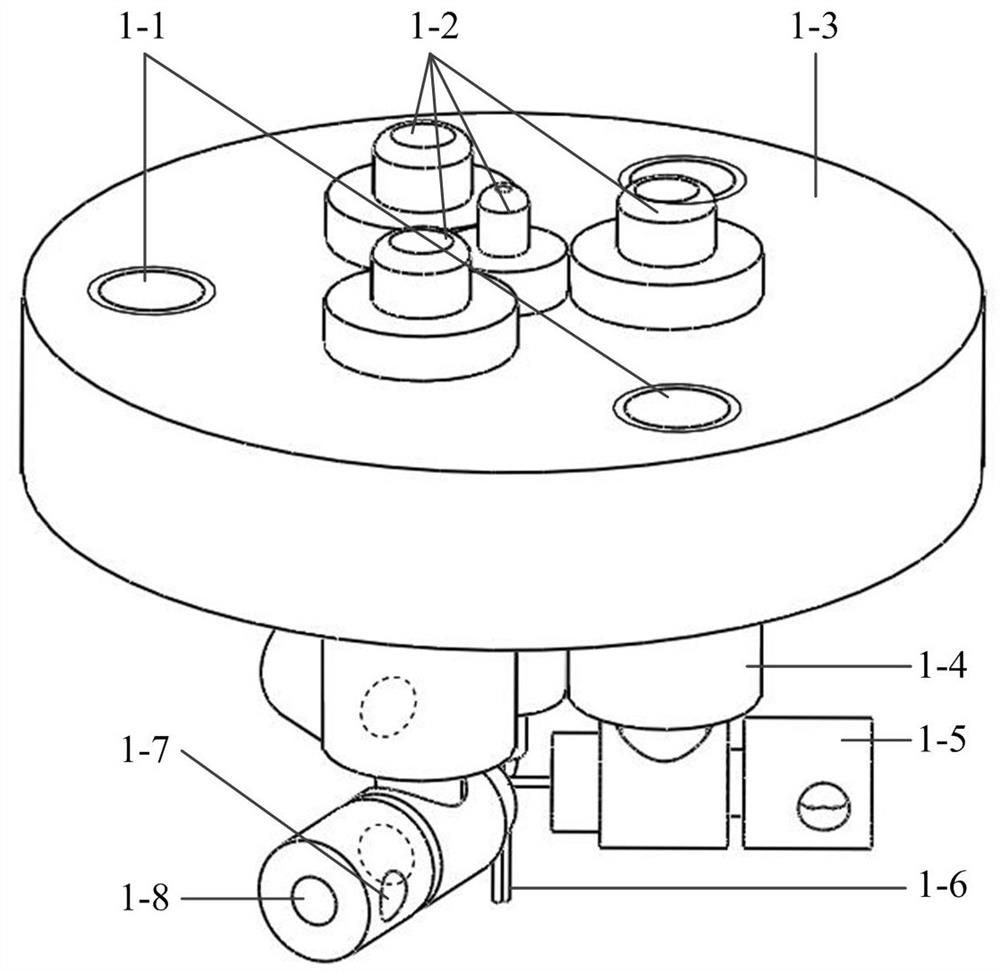

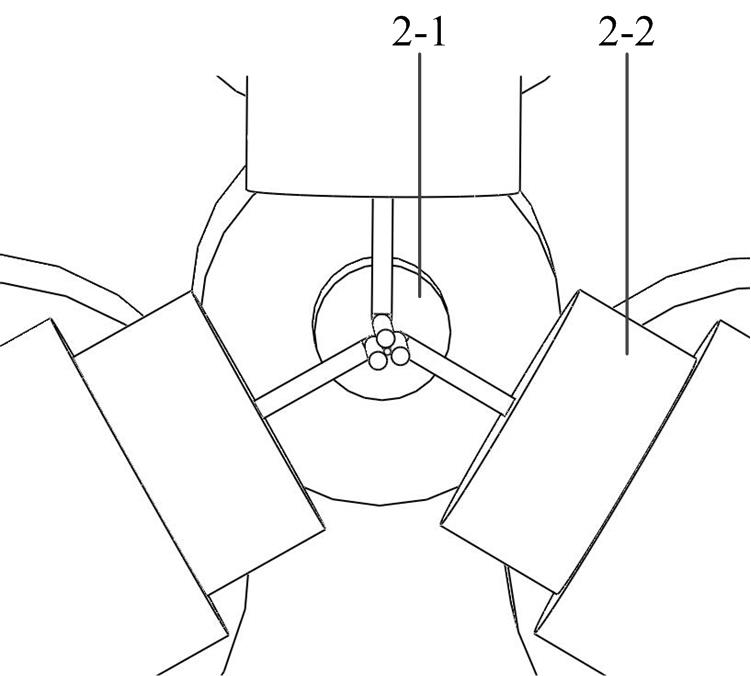

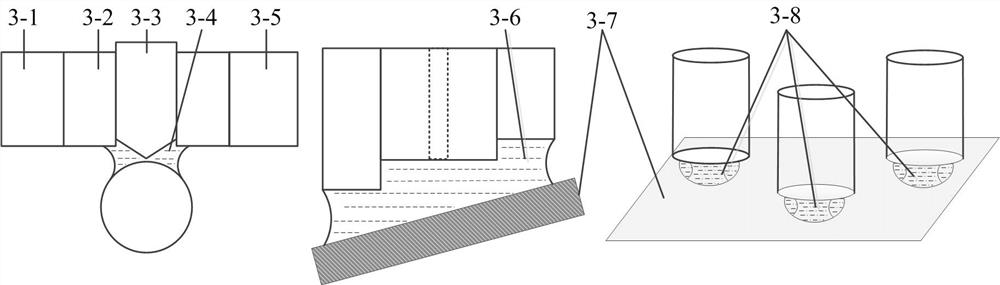

[0018] Specific implementation mode one: combine figure 1 , figure 2 with image 3 Explain, a four-needle integrated condensation compliance control micro-component operating device described in this embodiment includes a micro-drive motor 1-2, an adapter plate 1-3, three uniformly distributed threaded adapter holes 1-1, Integrated piezoelectric ceramic driver 1-4, refrigeration adapter 1-5, central shaft connector 2-1, probe adapter 2-2 and integrated probe 1-6, micro drive motor 1-2 installation On the adapter board 1-3, one end of the integrated piezoelectric ceramic driver 1-4 is axially connected to the micro drive motor 1-2, and the other end is fixedly connected to the probe adapter 2-2, and the integrated probe 1-6 Including No. 1 probe 3-1, No. 2 probe 3-2, No. 3 probe 3-5 and spindle probe 3-3, probe adapter 2-2 connected to cooling adapter 1-5, spindle The probe 3-3 is fixedly connected to the central shaft connector 2-1.

specific Embodiment approach 2

[0019] Specific implementation mode two: combination figure 1 , figure 2 with image 3 Note that the No. 1 probe 3-1, the No. 2 probe 3-2 and the No. 3 probe 3-5 in this embodiment are uniformly arranged at 120 degrees, and the spindle probe 3-3 is arranged in the center. Such setting is convenient for angle adjustment, and brass straightened wire or stainless steel straight wire can be used as the probe, and other components and connections are the same as those in Embodiment 1.

specific Embodiment approach 3

[0020] Specific implementation mode three: combination figure 1 , figure 2 with image 3 Note that the integrated probe 1-6 in this embodiment has a hydrophobic coating and exhibits a hydrophobic function, and the No. 1 probe 3-1, the No. 2 probe 3-2 and the No. 3-5 is connected and sealed with the probe adapter 2-2, the spindle probe 3-3 and the central shaft connector 2-1. Such setting is conducive to creating stable liquid medium conditions and adjusting the protruding angle of the probe. The probe can be treated with hydrophobicity by chemical etching and heptadecafluorodecyltrimethoxysilane. The other composition and connection relationship are the same as the specific embodiment 1. or two the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com