Cutting knife for die cutting

A cutting knife and die-cutting technology, which is applied in metal processing and other directions, can solve the problems of cutting tool cost waste, cutting knife scrapping, and small knife edge angle, etc., to save tool cost, prevent jamming or breaking, and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

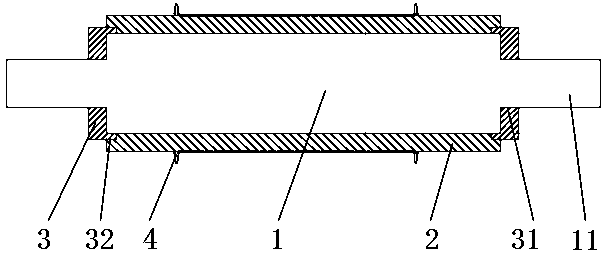

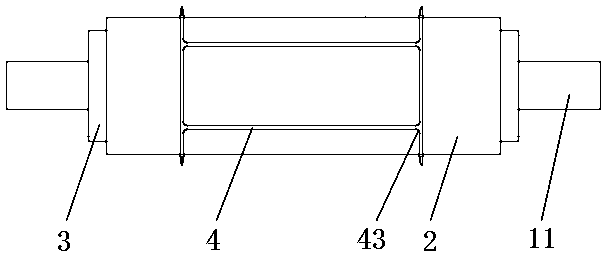

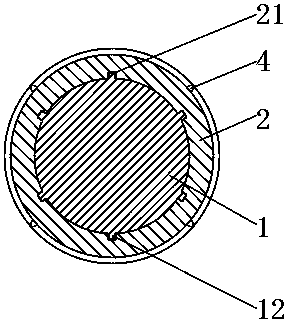

[0030] Example 1, see Figure 1-4 , the present invention provides a technical solution: a cutting knife for die-cutting, including a roller 1, a knife sleeve 2, a shaft sleeve 3 and a blade 4, the roller 1 is a cylindrical structure, and the two sides of the roller 1 A roller shaft 11 is provided, and the outer wall of the roller 1 is evenly fixed with six bumps 12, the bumps 12 are strip-shaped structures, and the length of the bumps 12 is 4 / 5 of the length of the roller 1, so The protrusion 12 is parallel to the axis of the roller 1, and the outer wall of the roller 1 is provided with first threads 13 on both sides.

[0031] The outer side of the roller 1 is movably connected with a knife cover 2, the knife cover 2 is a cylindrical structure, and the inner wall of the knife cover 2 is uniformly provided with a groove 21 matching the bump 12, and the knife cover 2 passes through the The groove 21 and the protrusion 12 are slidably connected with the roller 1, which facilita...

Embodiment 2

[0036] Example 2, see Figure 7 , the present invention provides a technical solution: a cutting knife for die-cutting, including a roller 1, a knife sleeve 2, a shaft sleeve 3 and a blade 4, the roller 1 is a cylindrical structure, and the two sides of the roller 1 A roller shaft 11 is provided, and a second thread 14 is evenly opened in the middle of the outer wall of the roller 1, and the length of the second thread 14 is 4 / 5 of the length of the roller 1, and the roller 1 passes through the second thread. 14 is threadedly connected with the tool holder 2, and first threads 13 are provided on both sides of the outer wall of the roller 1.

[0037] see Figure 1-3 The outer side of the roller 1 is movably connected with a knife cover 2, the knife cover 2 is a cylindrical structure, and the inner wall of the knife cover 2 is uniformly provided with a groove 21 matching the bump 12, and the knife cover 2 passes through the The groove 21 and the protrusion 12 are slidably conn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height dimension | aaaaa | aaaaa |

| Height dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com