3D printing device for jet molding through combination of liquid metal and photosensitive resin

A photosensitive resin, jet printing technology, applied in the direction of additive processing, can solve the problem of layer-by-layer printing without liquid metal and photosensitive resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

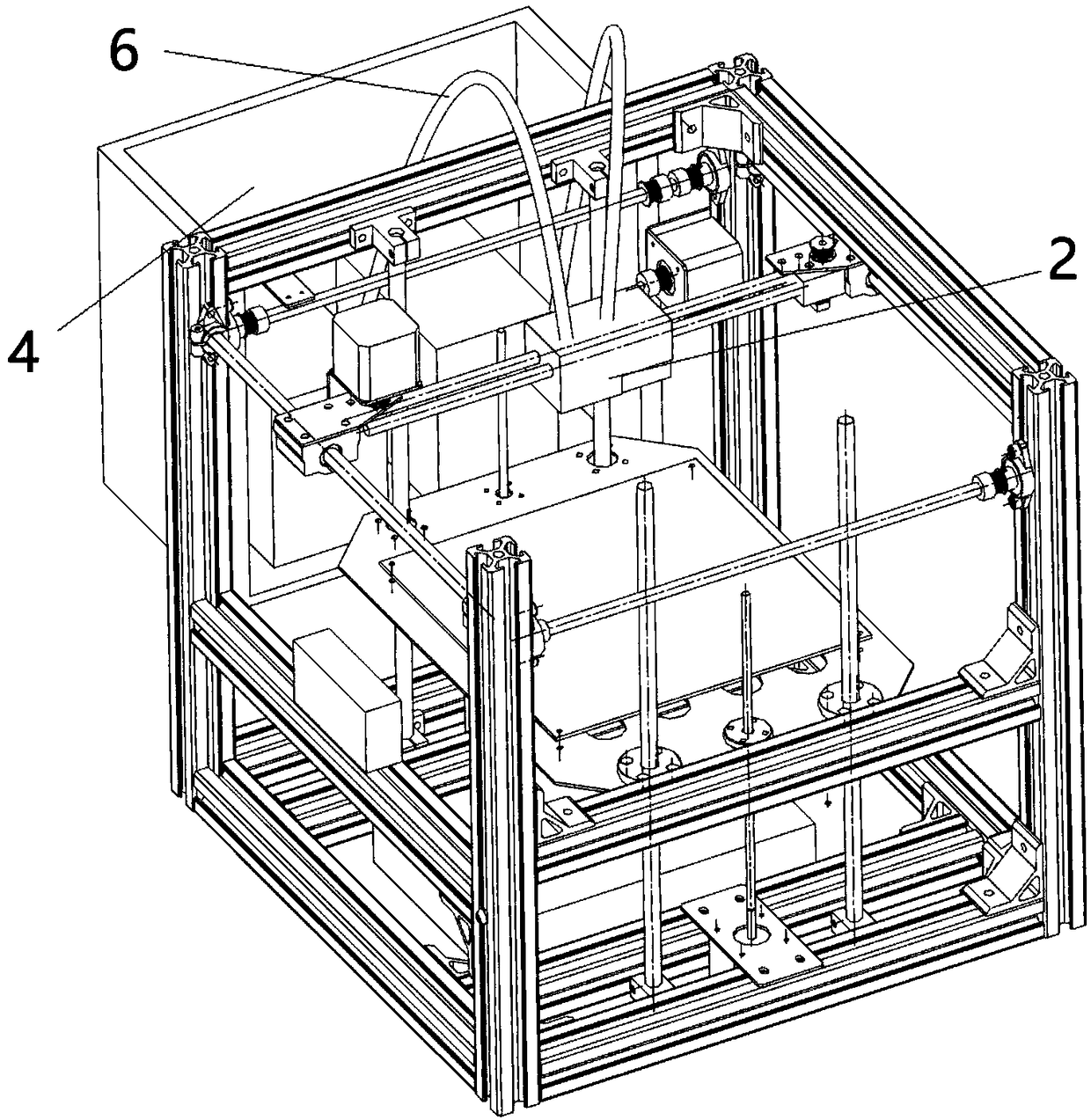

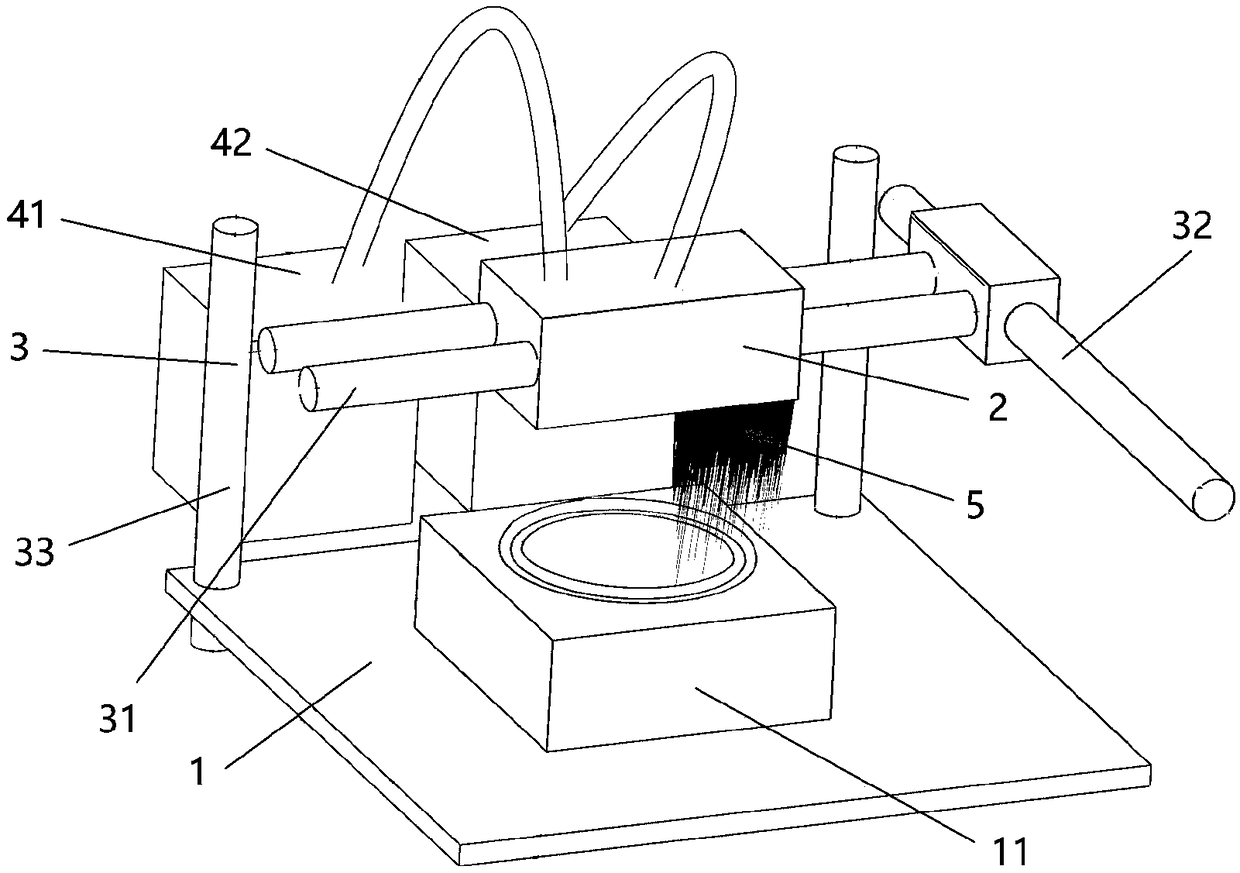

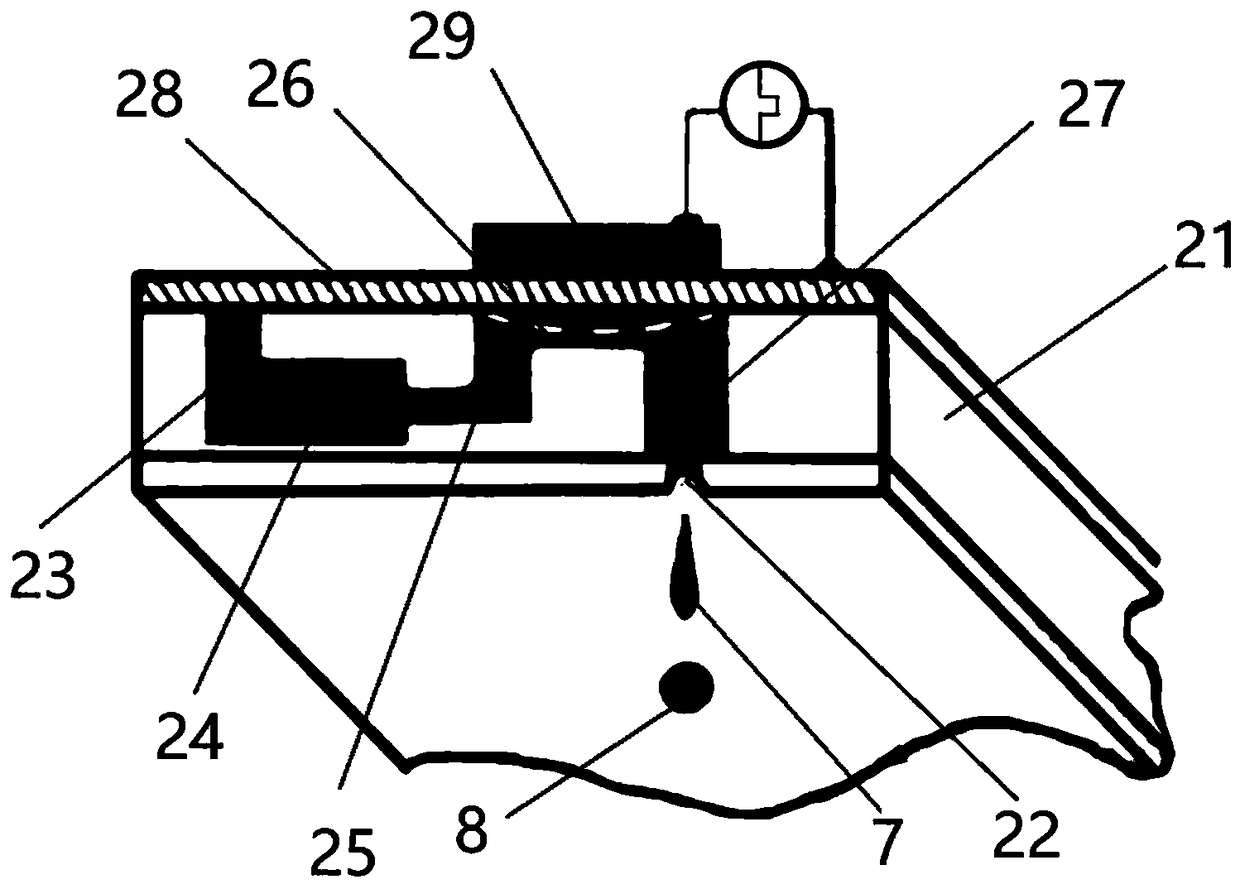

[0029] Such as figure 1 and figure 2 As shown in the figure, the 3D printing device schematically shows that the 3D printing device includes a loading tray 1 , a jetting printing mechanism 2 , a motion control mechanism 3 , an ink supply mechanism 4 and a UV lighting structure 5 .

[0030] In the embodiment of the present application, an area 11 to be printed is formed on the upper surface of the loading tray 1 .

[0031] The jetting and printing mechanism 2 is arranged above the loading tray 1 , wherein the jetting surface of the jetting and printing mechanism 2 faces the region 11 to be printed.

[0032] The motion control mechanism 3 is used to control the spray head ejection printing mechanism 2 to move toward the area to be printed 11 and to perform 3D printing within the area of the area to be printed 11 .

[0033] The ink supply mechanism 4 is used to supply liquid metal and photosensitive resin to the jetting printing mechanism 2 for 3D printing.

[0034]The UV l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com