Polymer precursor porous magnetic ceramic system based on 3D printing technology and preparation method thereof

A magnetic ceramic and 3D printing technology, which is applied to ceramic products, other household appliances, applications, etc., can solve the problems of many cracks and the inability to prepare porous ceramics, etc., achieve strong oxidation resistance, good electromagnetic absorption performance, and reduce preparation time. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

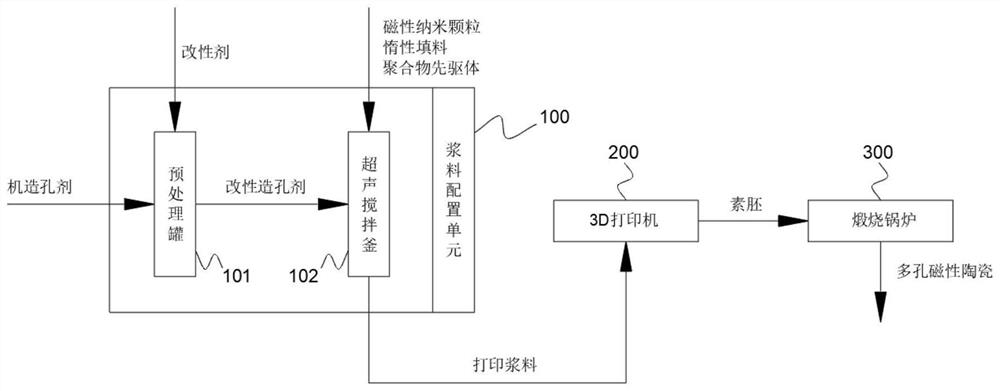

[0041] Such as figure 1 As shown, a polymer precursor porous magnetic ceramic system based on 3D printing technology, the system includes: a slurry configuration unit 100, a 3D printer 200 and a calcination boiler 300;

[0042] The slurry configuration unit 100 includes: a pretreatment tank 101 and an ultrasonic stirring tank 102;

[0043] The pretreatment tank 101 is used to prepare a modified pore-forming agent,

[0044] The ultrasonic stirring tank 102 is used to add the modified pore forming agent, magnetic nanoparticles, inert filler and polymer precursor into the organic solvent for stirring and mixing, and the organic solvent is volatilized by ultrasonic treatment to obtain the printing paste;

[0045] The 3D printer 200 uses the printing paste to print to obtain the blank;

[0046] The calcining boiler 300 calcines the green body to obtain porous magnetic ceramics.

[0047] The preparation system has a simple structure and a simple process flow, can make full use of...

Embodiment 2

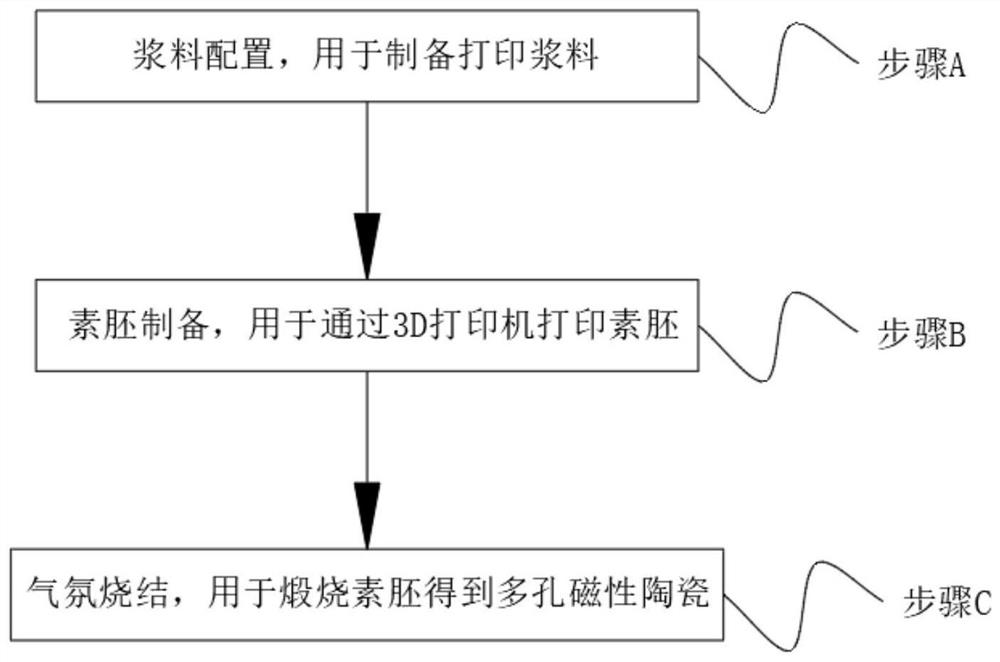

[0049] Such as figure 2 As shown, the present invention also provides a preparation method for preparing the porous magnetic ceramics, comprising the following steps:

[0050] A: slurry configuration

[0051] Pour the organic pore-forming agent into the pretreatment tank, and add a modifying agent for modification to obtain a modified pore-forming agent;

[0052] Add the modified pore-forming agent, magnetic nanoparticles, inert filler and polymer precursor into the ultrasonic stirring tank, add an organic solvent for high-speed stirring and mixing, and volatilize the organic solvent through ultrasonic treatment to obtain printing paste;

[0053] Among them: the mass ratio of pore-forming agent: nano-magnetic particles: inert filler: ceramic precursor is: 5-50: 1-20: 1-20: 50-150, and the printing paste is in 1s -1 The viscosity at the shear rate is 200Pa·s-1500Pa·s;

[0054] B: Preparation of plain embryos

[0055] The printing paste obtained in step A is placed in a 3D ...

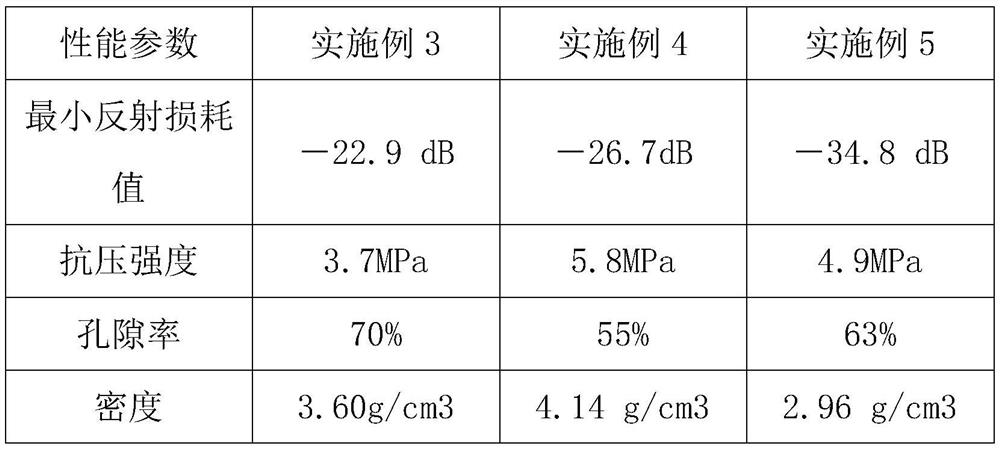

Embodiment 3

[0065] The preparation of the porous magnetic ceramics comprises the following steps:

[0066] A: slurry configuration

[0067] Pretreatment of nanocrystalline cellulose with silane coupling agent KH570 to obtain modified nanocrystalline cellulose;

[0068] Add modified nanocrystalline cellulose, tetrairon sesquioxide nanoparticles coated with silane on the surface, silicon carbide powder and polycarbosilane into n-hexane and mix at high speed, then ultrasonically treat, and volatilize part of the organic solvent to obtain printing paste;

[0069] Among them: modified nanocrystalline cellulose, tetrairon sesquioxide nanoparticles coated with silane on the surface, silicon carbide powder and polycarbosilane mass ratio: 20:6:12:120, the printing paste was sheared at 1s-1 The viscosity at the speed is 656Pa·s;

[0070] B: Plain embryo preparation: put the printing paste in a 3D printer to obtain a plain embryo through ink direct writing 3D printing;

[0071] C: Atmosphere sint...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tackiness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com