Diaphragm structure of automobile upright post

A technology for pillars and automobiles, which is applied to superstructures, superstructure subassemblies, vehicle components, etc., and can solve problems such as the lack of improvement in the impact resistance of central pillars, poor bending and torsional strength, and affecting welding accuracy. Achieve high bending and torsional strength, high self-rigidity, and improve impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

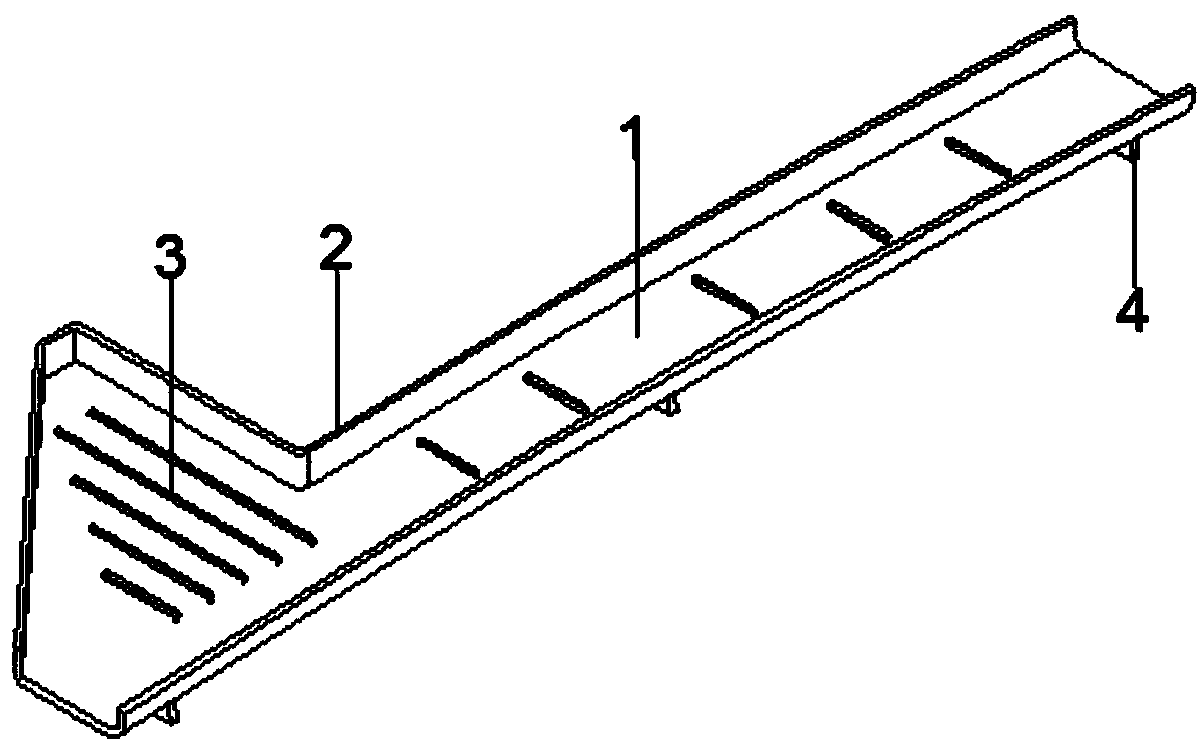

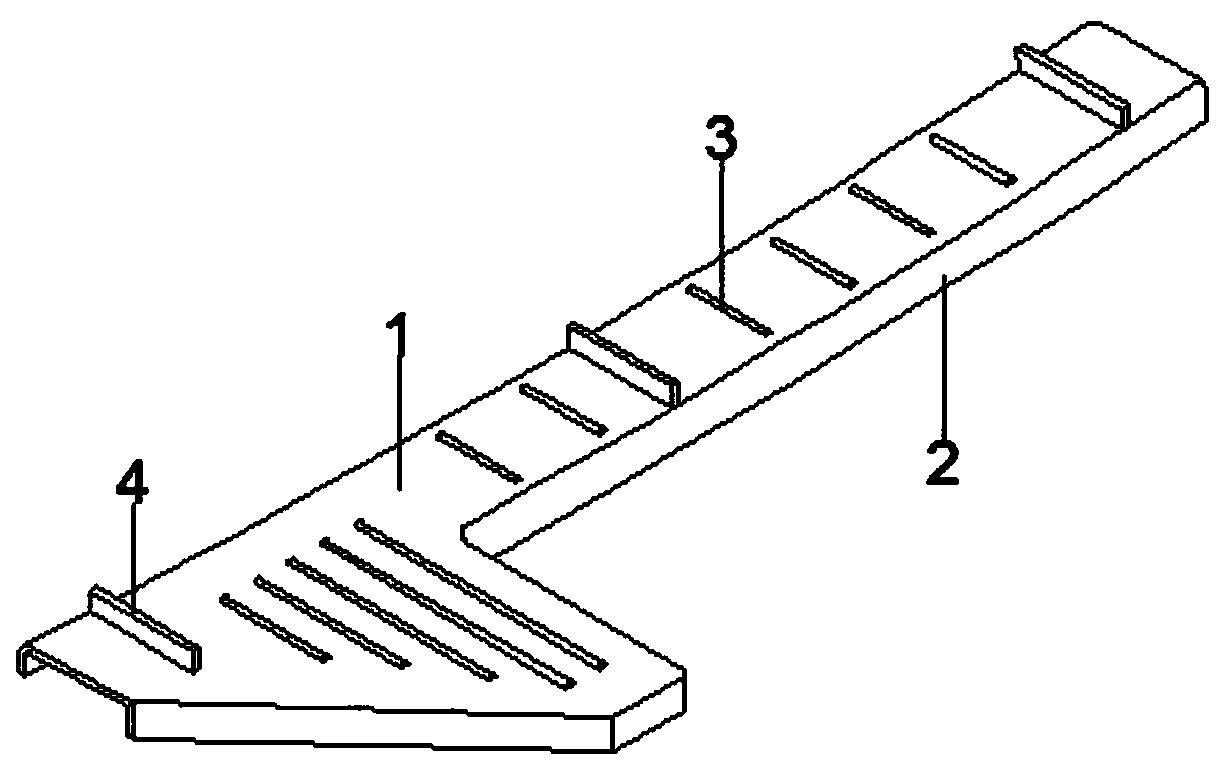

[0026] The car column partition structure includes: a board body 1, a flange 2, a reinforcing rib 3, and a connecting plate 4; the flange 2 is located on both sides of the board body 1, and the flange 2 and the board body 1 are an integral structure; The reinforcing rib 3 is located inside the plate body 1, and the reinforcing rib 3 is integrated with the plate body 1; the connecting plate 4 is arranged on the back of the plate body 1, and the connecting plate 4 and the plate body 1 are connected by welding. connect.

[0027] Specifically, the plate body 1 is a central pillar assembly of an automobile body with a rectangular upper part and a triangular lower part.

[0028] Specifically, the flange 2 is formed by bending at an angle of 90° along both sides of the plate body 1, and the bending height of the flange 2 is 5 mm.

[0029] Specifically, the reinforcing ribs 3 are elongated arc-shaped protrusions, and there are at least six reinforcing ribs 3 arranged horizontally on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com