Rumination type extruder and rumination extrusion method

An extruder and ruminant technology, which is applied in the field of plastic extruder manufacturing, can solve the problems that the power and the number of revolutions cannot be greatly increased, the torque of the screw is increased, and the output limit is difficult, so as to save material costs and floor space. , The effect of improving torsional and bending strength and easy to ensure machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

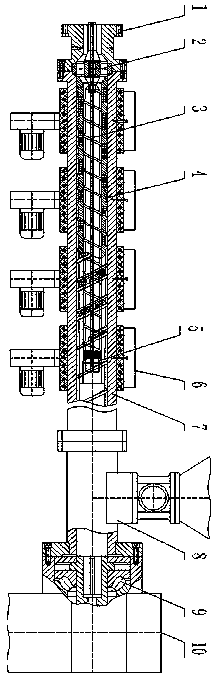

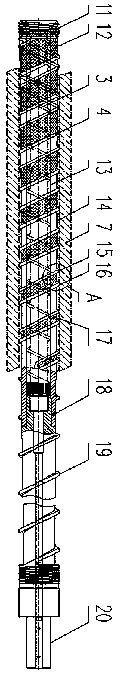

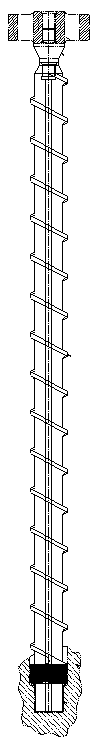

[0015] Embodiment 1: with reference to attached Figure 1-4 . A ruminant type extruder, comprising a mold or a transition 1, a rectifying disc 2, a screw, a sliding thrust sleeve 5, a heater 6, a main screw barrel 7, a feeding seat 8, a thrust bearing 9, and a reduction box 10, the screw It is composed of a sub-screw 3 and a female screw 4. The front section of the female screw 4 is a hollow section, and an additional thread 15 is added between the main threads 16 of the hollow section. The thrust surface starts and gradually forms an additional thread groove 17 that gradually widens with the main thread. The bottom of the screw groove is provided with a through hole or a long hole 12, forming a sieve-shaped bottom groove. The sub-screw 3 is installed concentrically in the hollow section of the female screw 4 and the thread direction on the sub-screw 3 is opposite to that of the female screw 4 . The female screw 4 is both a screw and a screw barrel of the sub-screw 3, and t...

Embodiment 2

[0020] Example 2: On the basis of Example 1, an extrusion method of a ruminant extruder, the raw material is conveyed forward through the rotation of the female screw 4, and enters the hollow core under the dual action of an external heat source and its own shear heat. The section begins to melt gradually, and the partially melted raw material enters the additional screw channel 17 through the gap of the additional screw thread 15 of the hollow section, and the unmelted raw material continues to be transported forward and continues to melt and enter the additional screw channel 17 while melting until the front end is completely melted And all enter additional screw groove 17. The molten raw material entering the additional screw groove 17 of the female screw 4 forms a high pressure under the action of the screw, forcing the molten raw material to enter the sub-screw 3 through the sieve-like groove bottom 12 of the additional screw groove. At this time, the female screw 4 transf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com