Cast-in-place pile construction method suitable for drilling and bottom expanding device

A construction method and cast-in-place pile technology, which are applied to sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of large stirring resistance, increased drilling resistance, and inability to promote, and achieve high bending and torsional strength, improved The effect of vertical bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

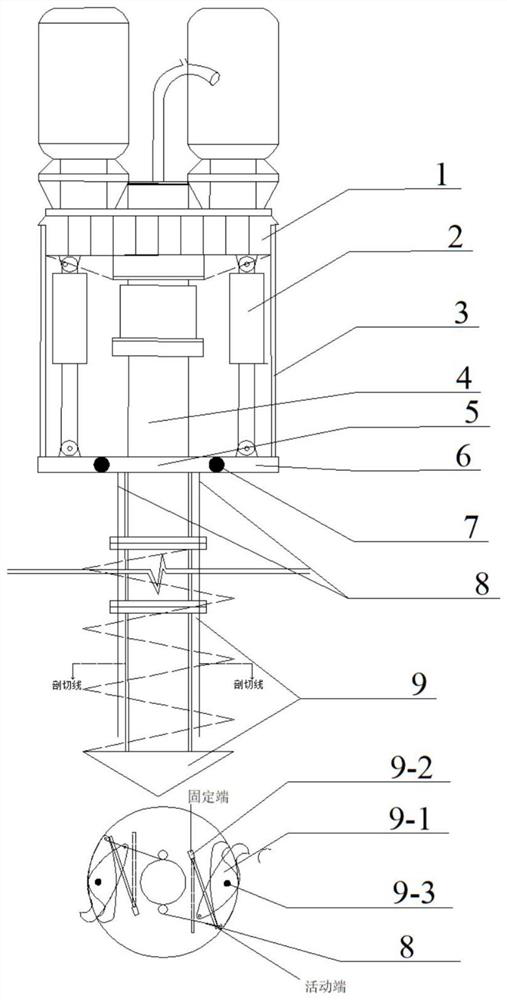

Method used

Image

Examples

Embodiment 2

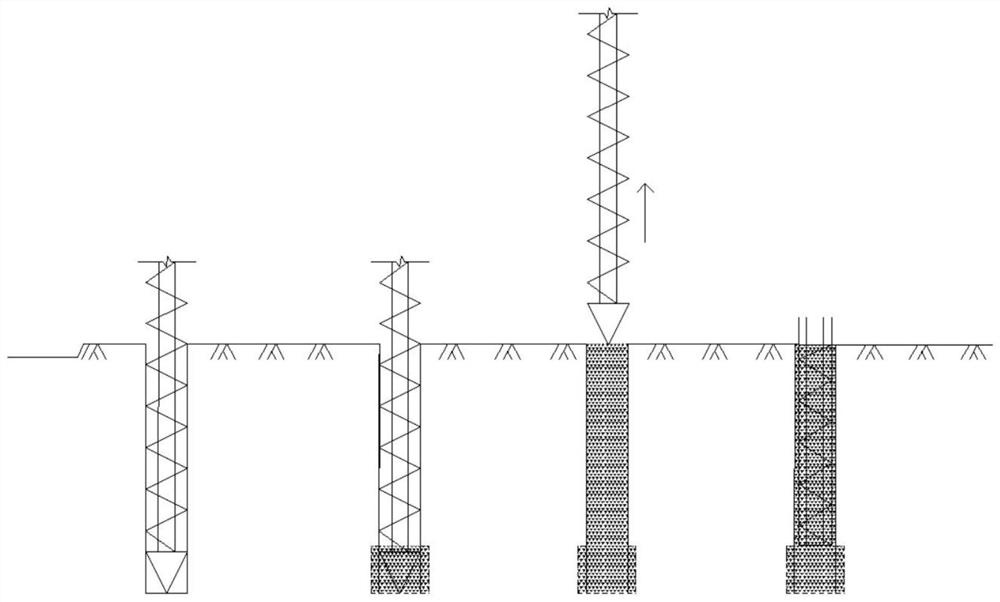

[0033] Example 2: Bottom-expanding pile with superfluid concrete for drilling and pressure grouting. The flow process when the method uses the example 1 drilling bottom expansion device is: when the borehole pressure grouting superfluid concrete pile is drilled into the design elevation, the drilling pressure grouting superfluid concrete (or cement slurry) is fed by the two ends of the power head lower end The side hydraulic cylinder pulls the mechanical turntable to drive the steel wire rope. The lower end of the steel wire rope is connected to the blade of the drill bit and the upper expansion cutter is stretched outward. While rotating and lifting the drill, the bottom is expanded, and the sand at the end of the expanded pile is mixed with superfluid concrete (or cement slurry). After forming the enlarged end, lift the drill and continue to press pour the superfluid concrete to place the reinforcement cage to form a drill hole press pour superfluid concrete bottom expansion ...

Embodiment 3

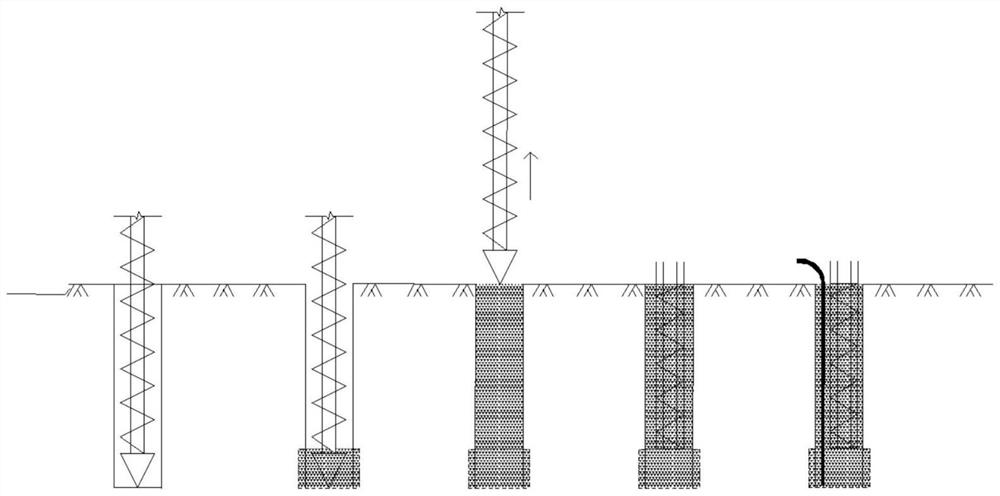

[0035]Example 3: Grouting piles after borehole pressure grouting and superfluid concrete bottom expansion. After the process of using the example 1 drilling bottom expansion device and the embodiment 2 drilling pressure pouring superfluid concrete bottom expansion pile in this method is completed, insert the grouting pipe immediately, clear the water in 6 hours, and inject it after two days The grouting pile is formed by grouting the cement slurry into the superfluid concrete with borehole pressure grouting and expanding the bottom.

[0036] see attached image 3 : Process flow chart of grouting pile after drilling and grouting;

Embodiment 4

[0037] Embodiment 4: Construction method of bored and bottom-expanded cast-in-situ piles in dry operation. When this method uses the drilling bottom expansion device of Example 1, the flow process is: when the drilling rig drills to the pile end design elevation, inject cement slurry and start the bottom expansion device, and lift the drill while stirring while grouting to expand the bottom and lift the drill Finally, the reinforcement cage is placed, and then the concrete is poured into the dry work bored bottom expansion pile.

[0038] see attached Figure 4 : Process flow chart of bored bottom expansion pile in dry operation;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com