Paper bowl automatic collection device

An automatic collection and paper bowl technology, applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problem that the paper bowls cannot be counted, stacked and sub-packed, the cup collection cannot be carried out continuously, and the stacking and collection quality of paper bowls cannot be well guaranteed. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

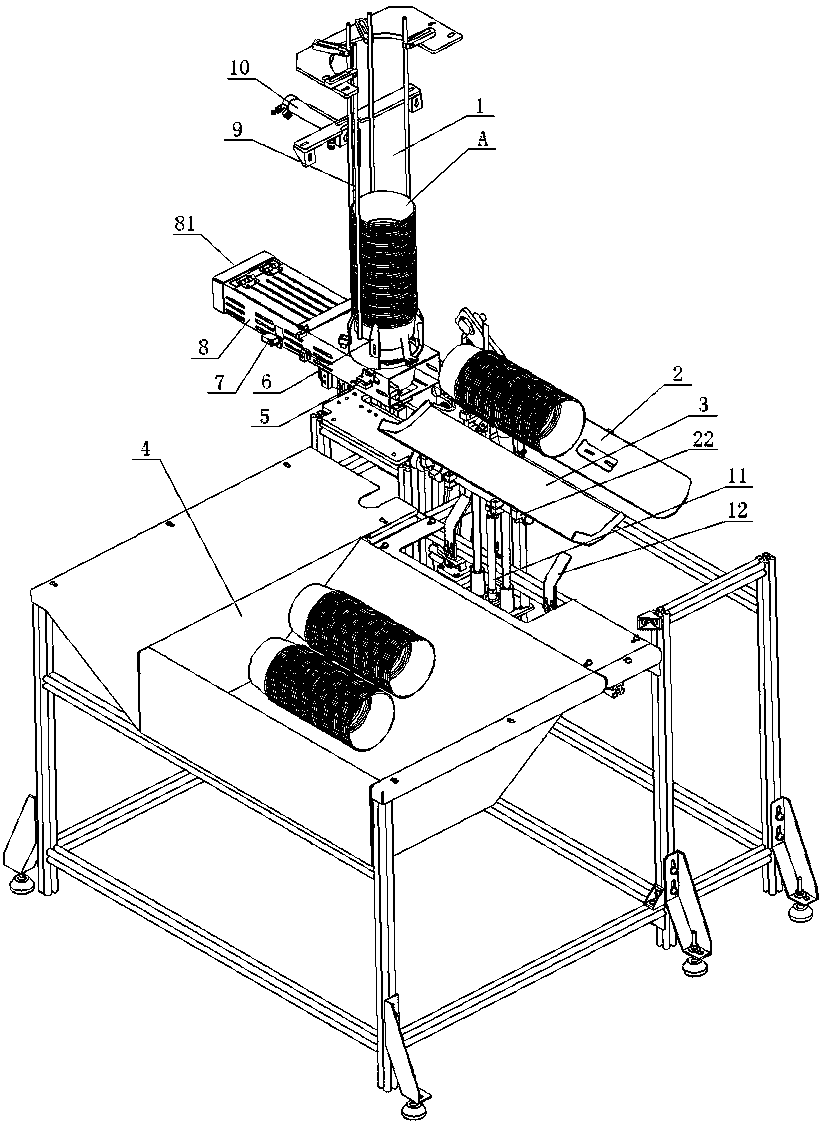

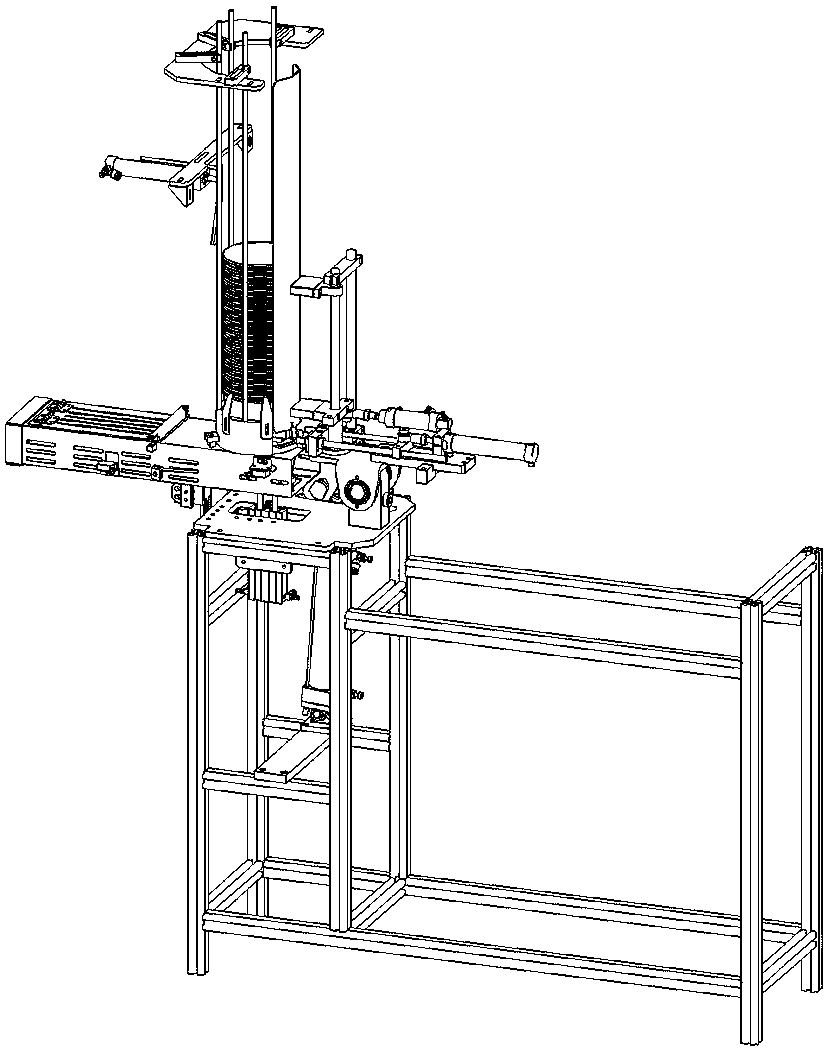

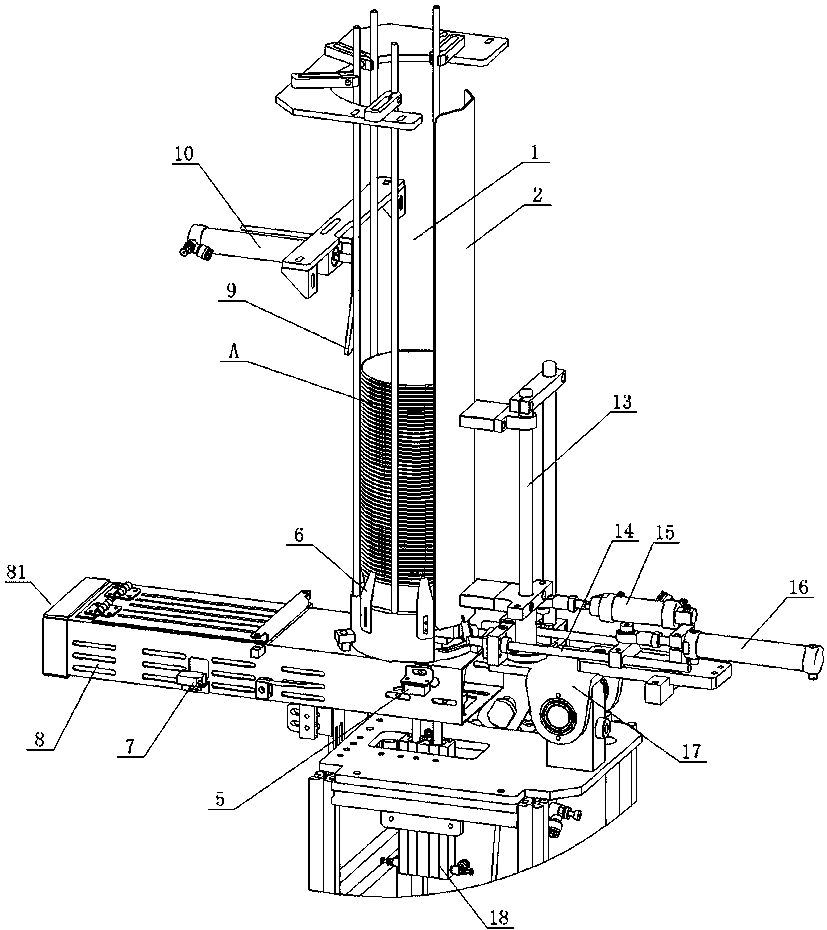

[0019] As shown in the figure, the automatic collection device for paper bowls of the present invention includes a cup collection enclosure 1, which has a cup collection opening 20, and the cup collection opening 20 is located at the bottom of the cup collection enclosure 1 (see Figure 5 ), there is a cup collector 8 under the cup collector 1, the cup collector 8 has a square lumen, and the bottom of the cup collector 8 is provided with a bowl pushing cylinder 18 to push the paper bowl 8 in the cup collector upwards into the cup collector. The cup enclosure cage 1, the top of the push rod of the bowl pushing cylinder 18 is connected to the bowl pushing block 19, the side of the cup collector 8 is provided with a cup connecting port 81 connected to the cup collecting pipeline, and the cup connecting port 81 is also square to connect the square cup collecting Pipeline, the front side of the cup receiver 8 is provided with a first optical eye 7 and a second optical eye 5, the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com