Automatic waveguide signal acquisition device for intelligent pressure vessel

A pressure vessel and automatic collection technology, applied in the direction of using wave/particle radiation devices to transmit sensing components, can solve problems such as fragmentation, high cost, and damage to structural integrity, and achieve the effect of improving data collection accuracy and solving high costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

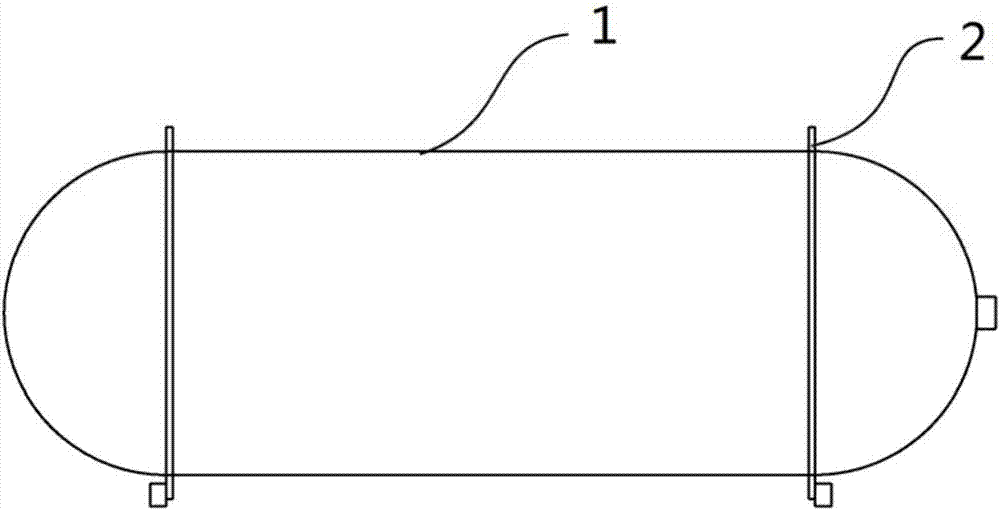

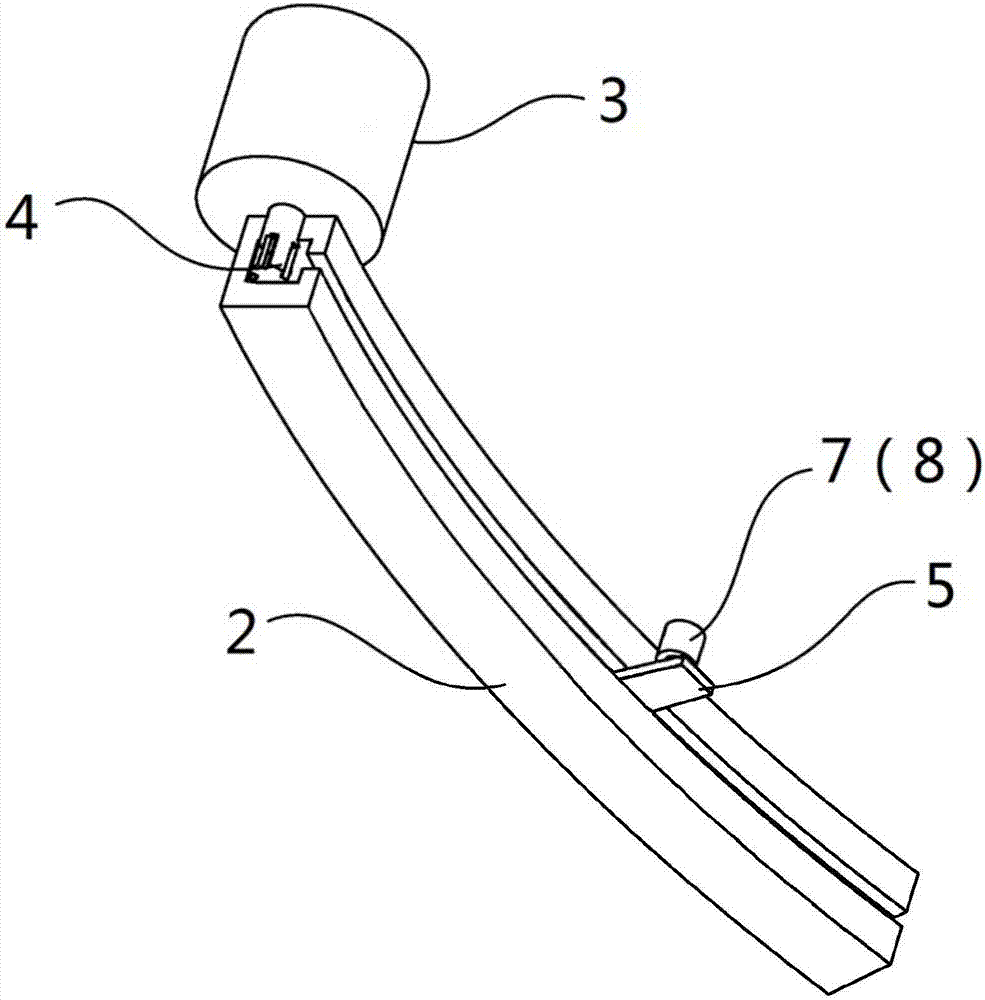

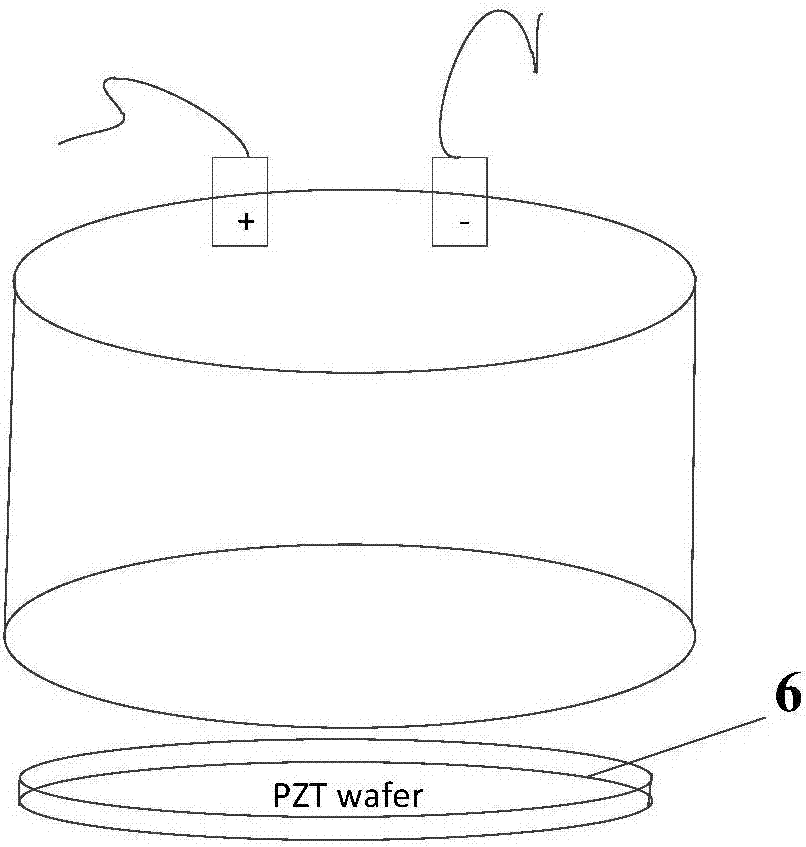

[0025] Such as Figure 1-Figure 2 As shown, this embodiment provides an automatic collection device for guided wave signals for intelligent pressure vessels, including two fixed components and a signal excitation terminal 7 and a signal receiving terminal 8 arranged in pairs, and the signal excitation terminal 7 and the signal receiving terminal 8 are respectively installed on a fixed assembly; the fixed assembly includes a guide rail 2, a drive mechanism and a mechanical handle 5, the guide rail 2 is installed on the surface of the pressure vessel 1, the drive mechanism is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com