Cable reel paying-off device

A technology of pay-off device and cable reel, which is used in transportation and packaging, transportation of filamentous materials, thin material handling, etc., can solve the problems of easy entanglement of cables, frictional damage of cables, and easy occurrence of danger, saving manpower. , The effect of smooth rotation, labor-saving and convenient straightening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

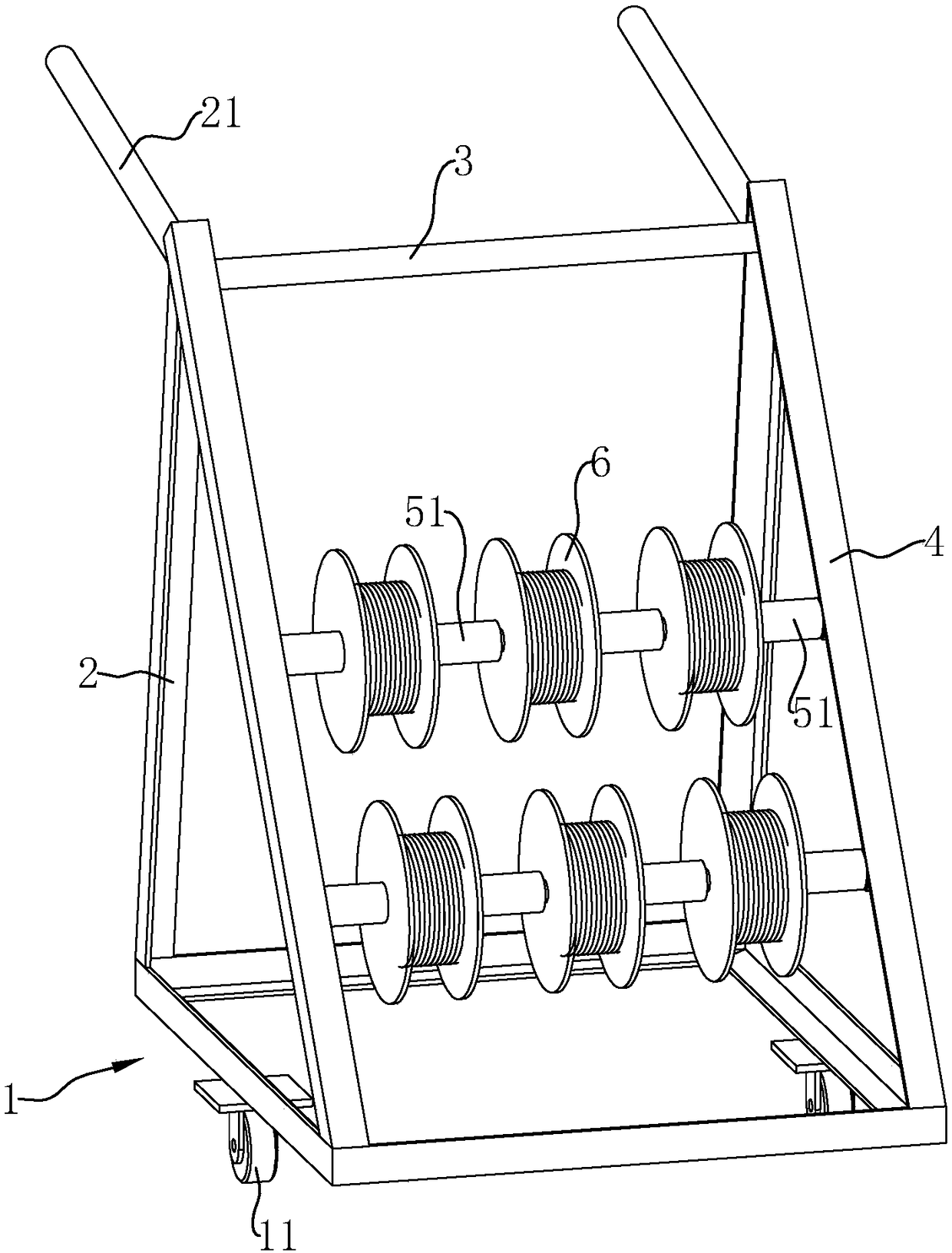

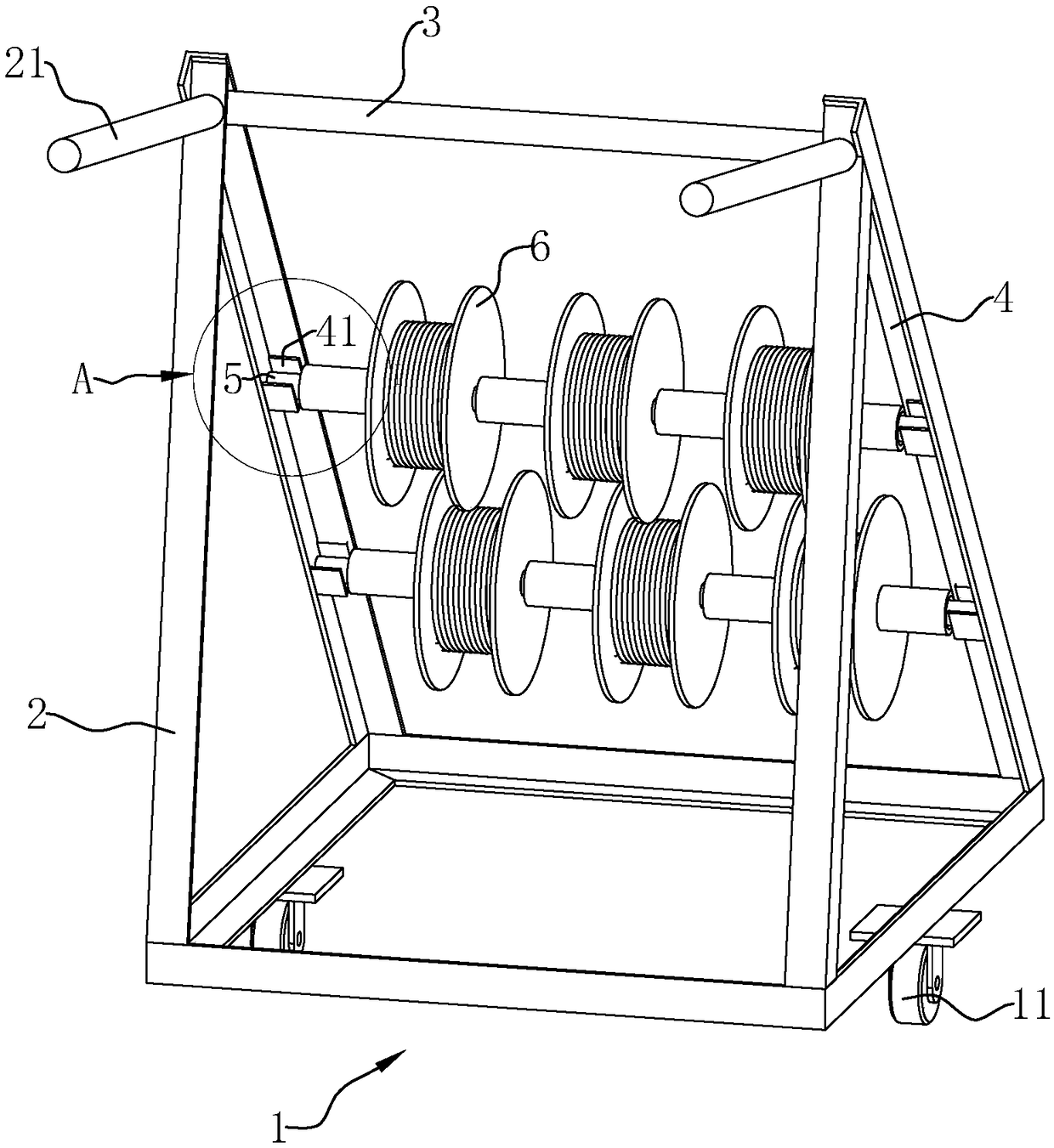

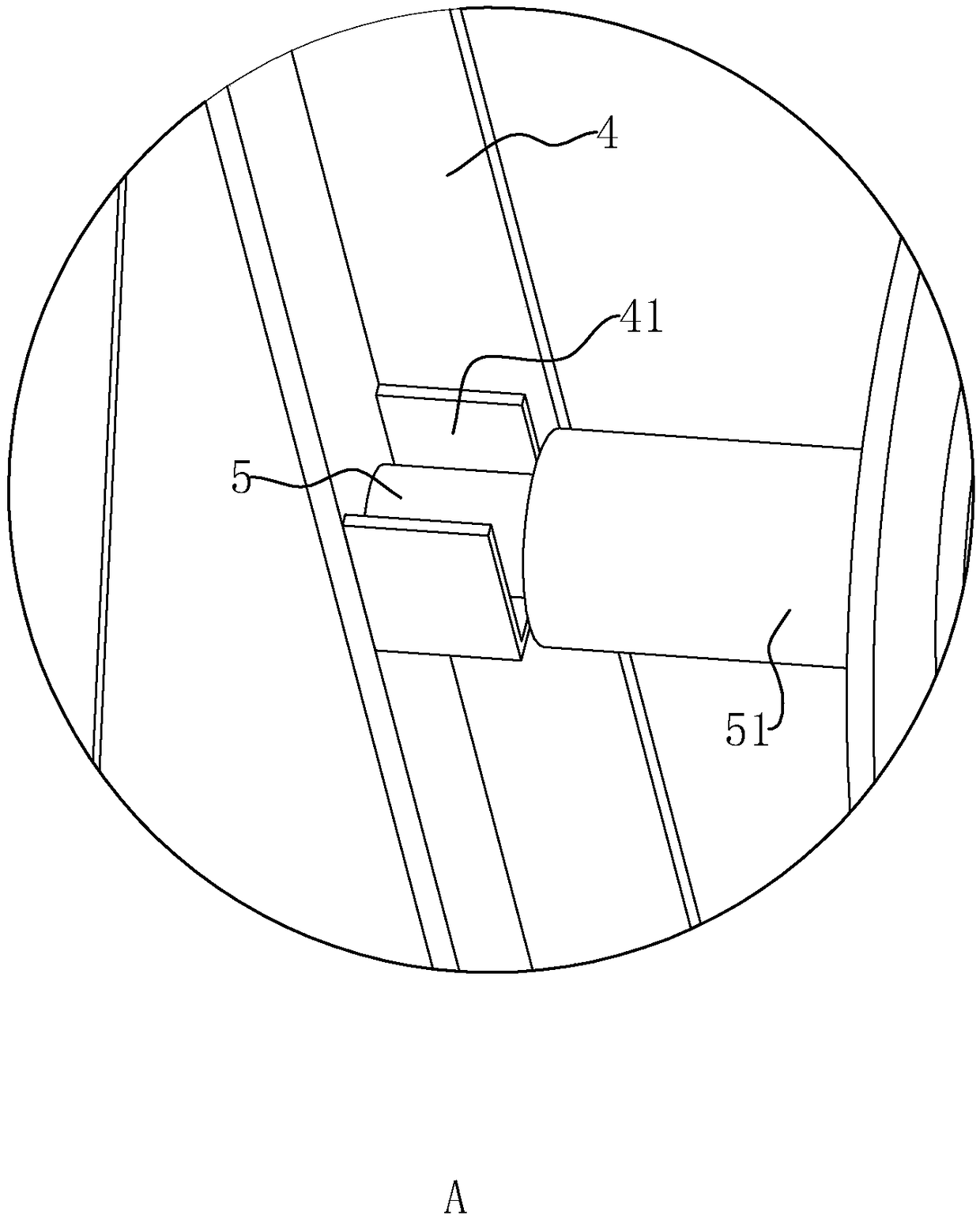

[0030] Embodiment: a kind of cable reel pay-off device, such as figure 1 with figure 2 As shown, it includes a support base 1 placed on the ground and a pair of load-bearing rods 2 arranged on the support base 1. The two load-bearing rods 2 are arranged parallel to each other, and the two load-bearing rods 2 are arranged horizontally. The connecting rod 3 is connected, and the connecting rod 3 is located at the end of the load-bearing rod 2 away from the supporting chassis 1 . A pair of support rods 4 are also arranged on the support chassis 1, and the two ends of the support rods 4 are fixedly connected to the two ends of the bearing rod 2 and the support chassis 1, respectively. Composite triangle frame.

[0031] The support rods 4 are arranged obliquely, and the angle formed between the plane where the two support rods 4 are located and the plane where the support chassis 1 is located is less than 90° and greater than 45°. The cross-section of the support rod 4 along it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com