Cable conveying device for coiled cable

A cable transmission and cable technology, which is applied in the field of cable transmission devices for coiled wires, can solve the problems of personnel injury and a large amount of manpower, and achieve the effects of stabilizing the direction of transmission, increasing friction, and stabilizing cable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

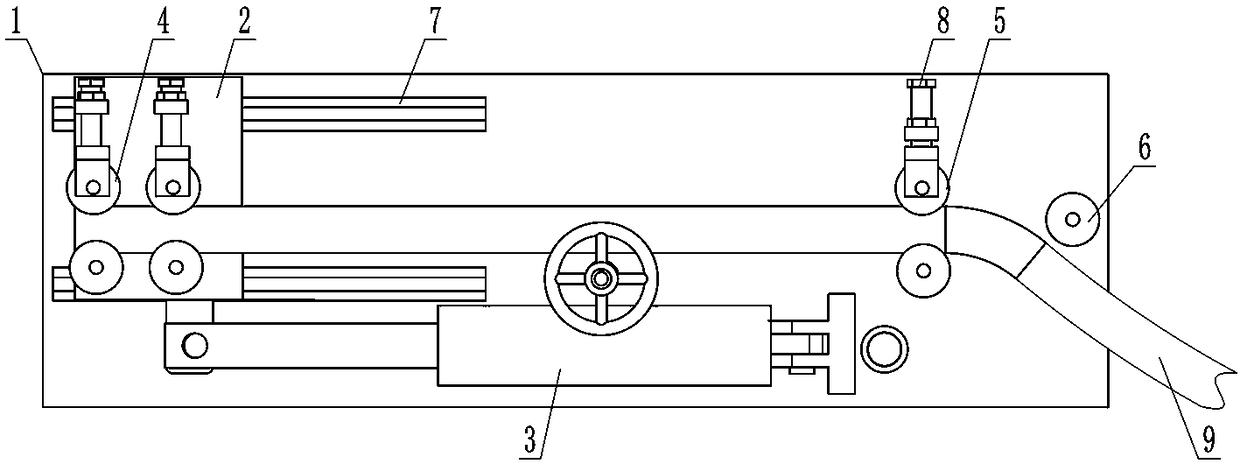

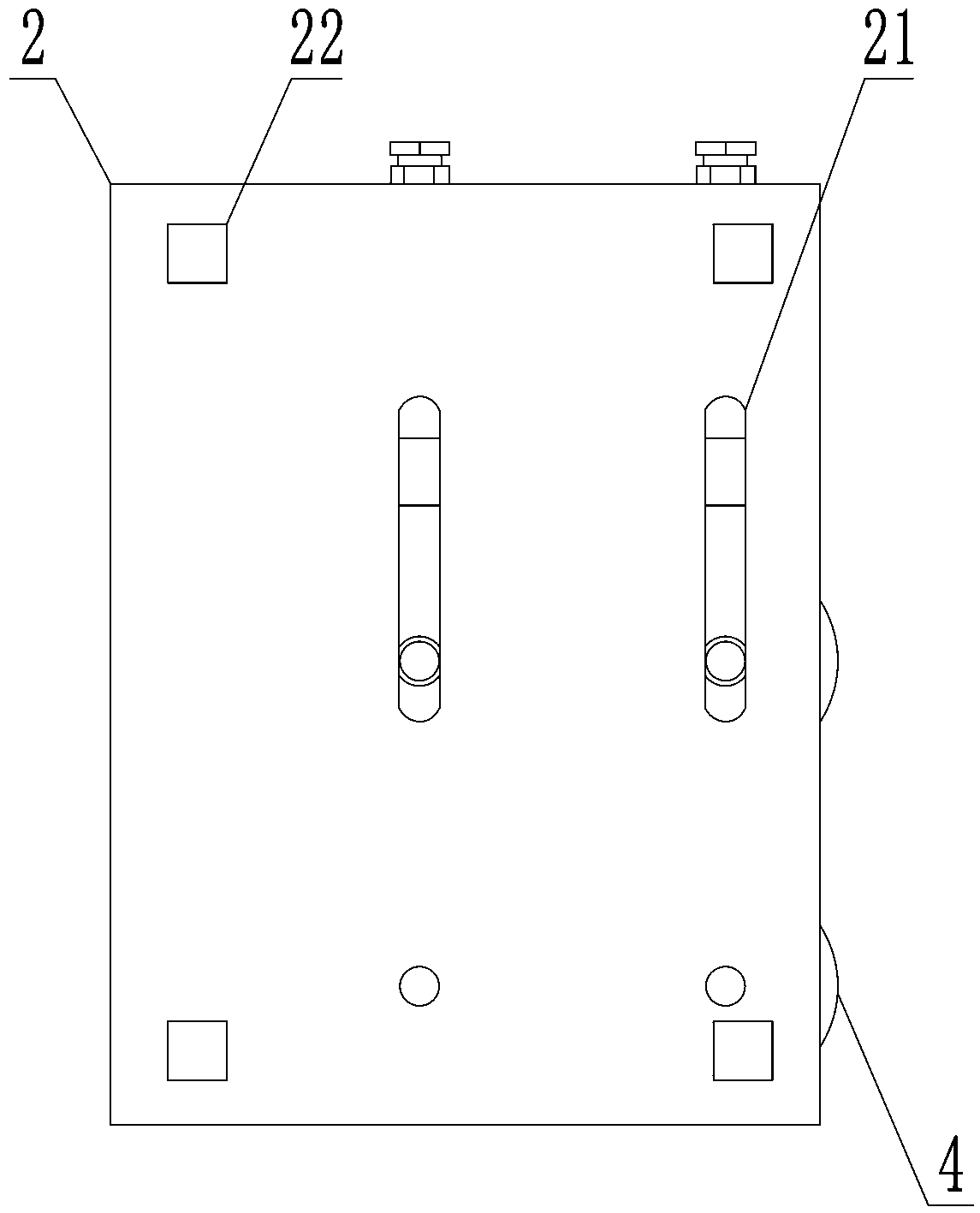

[0025] Such as figure 1 with figure 2 As shown, a cable conveying device for coiling wires includes a power mechanism, a wire inlet platform 1, a cable pushing mechanism arranged at the wire inlet end of the wire inlet platform 1, and a cable pulling mechanism arranged at the wire outlet end of the wire inlet platform 1 Pulling mechanism, the power mechanism can specifically be a hydraulic cylinder 3 or a hydraulic cylinder, the power mechanism drives the cable propulsion mechanism to advance and retreat along the direction of the line; when the cable propulsion mechanism advances along the direction of the line, the cable propulsion The mechanism is in a clamped state, and the cable pulling mechanism is in a relaxed state, so that the rear end clamps the wire and pushes forward together; when the cable pushing mechanism retreats along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com