Steel structure elevator shaft assembly

A technology for elevator shafts and steel structures, applied in the field of elevators, can solve problems such as safety accidents, large connection spans, and poor connection effects, and achieve the effects of reduced fixed span, reliable fixing, and high degree of adjustment freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be described in further detail below with reference to the drawings and specific implementations, but the present invention is not limited to these embodiments.

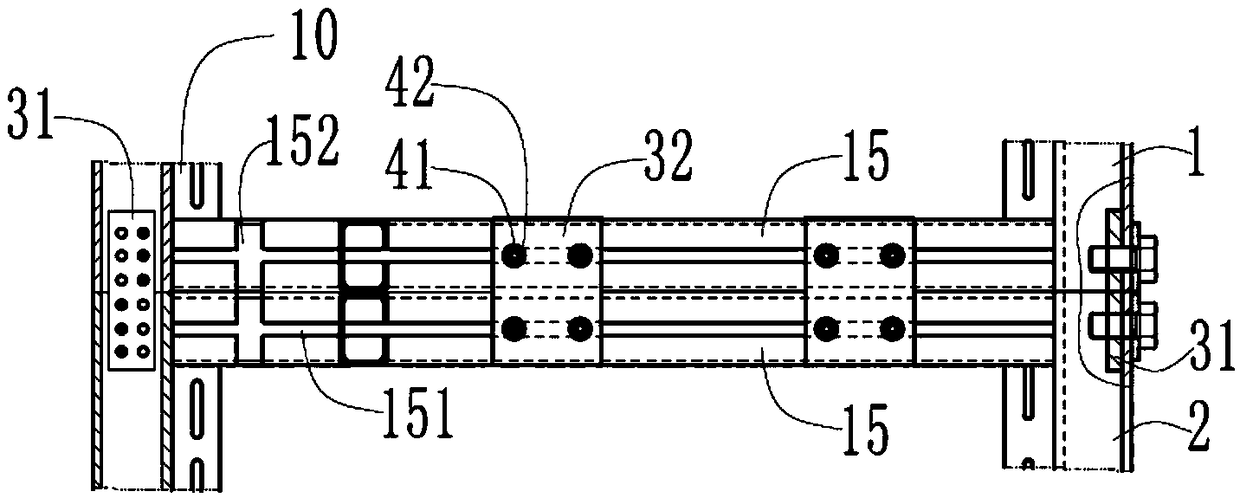

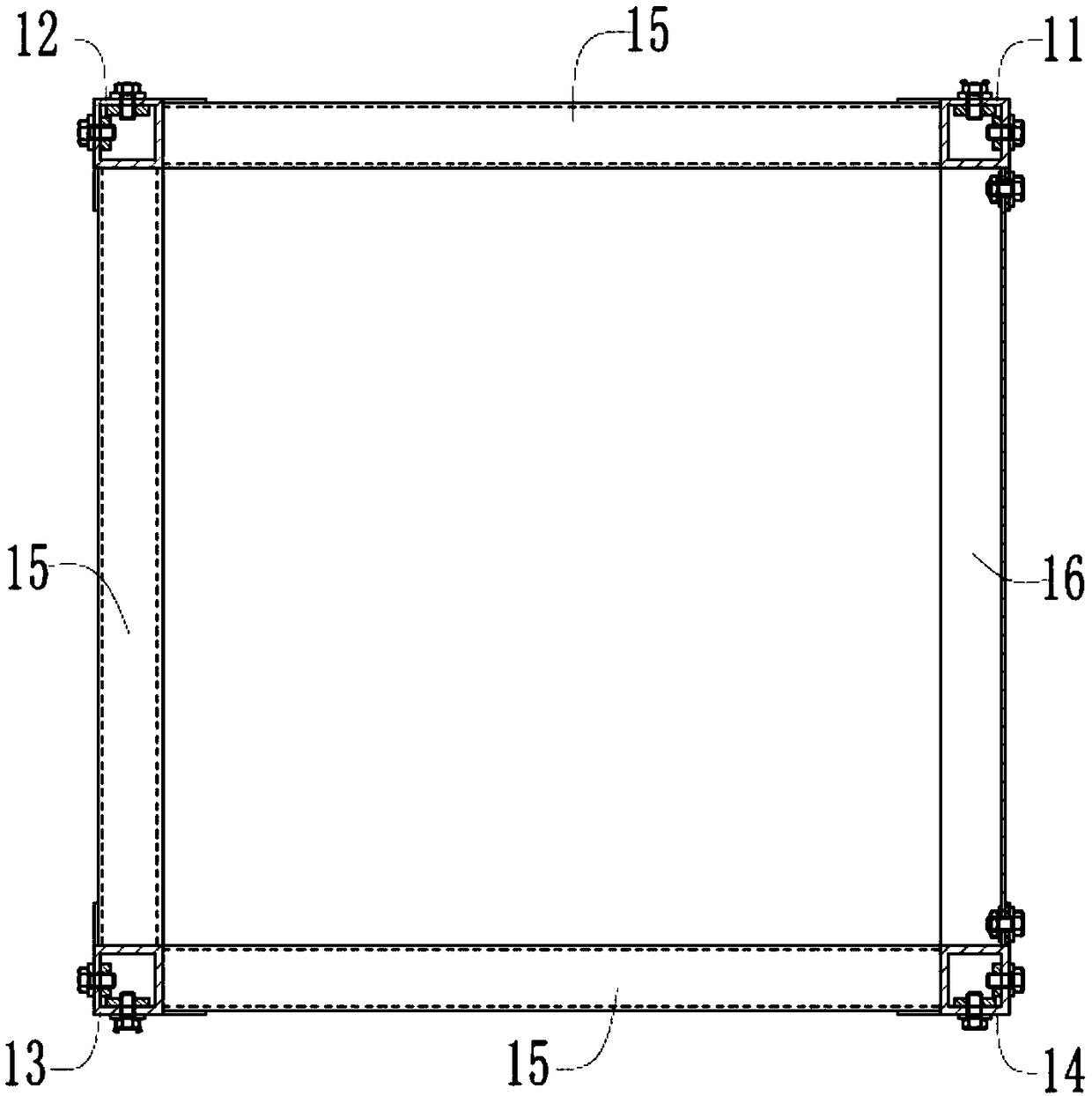

[0023] Such as figure 1 , figure 2 As shown, the steel structure elevator hoistway assembly of the present invention includes: an upper frame 1, a lower frame 2 and a connecting piece. The upper frame 1 and the lower frame 2 are fixedly connected by the connecting piece; the upper frame 1 includes a plurality of vertical The installed square steels are fixedly connected to each other by connecting steel 15; the side of the connecting steel is provided with a through groove 151 and an installation opening 152 perpendicular to the through groove. The lower frame 2 and the upper frame 1 are arranged symmetrically; the upper frame 1 and the lower frame 2 have the same structure and composition, and the upper frame and the lower frame are interchangeable during th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com