Mast cantilever crane

A technology of cantilever crane and mast, which is applied in the field of mast cantilever crane, can solve the problems of equipment cost and transportation, low utilization rate, high cost of crane pre-rotation, etc., and achieve the effect of reducing power, saving energy consumption and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

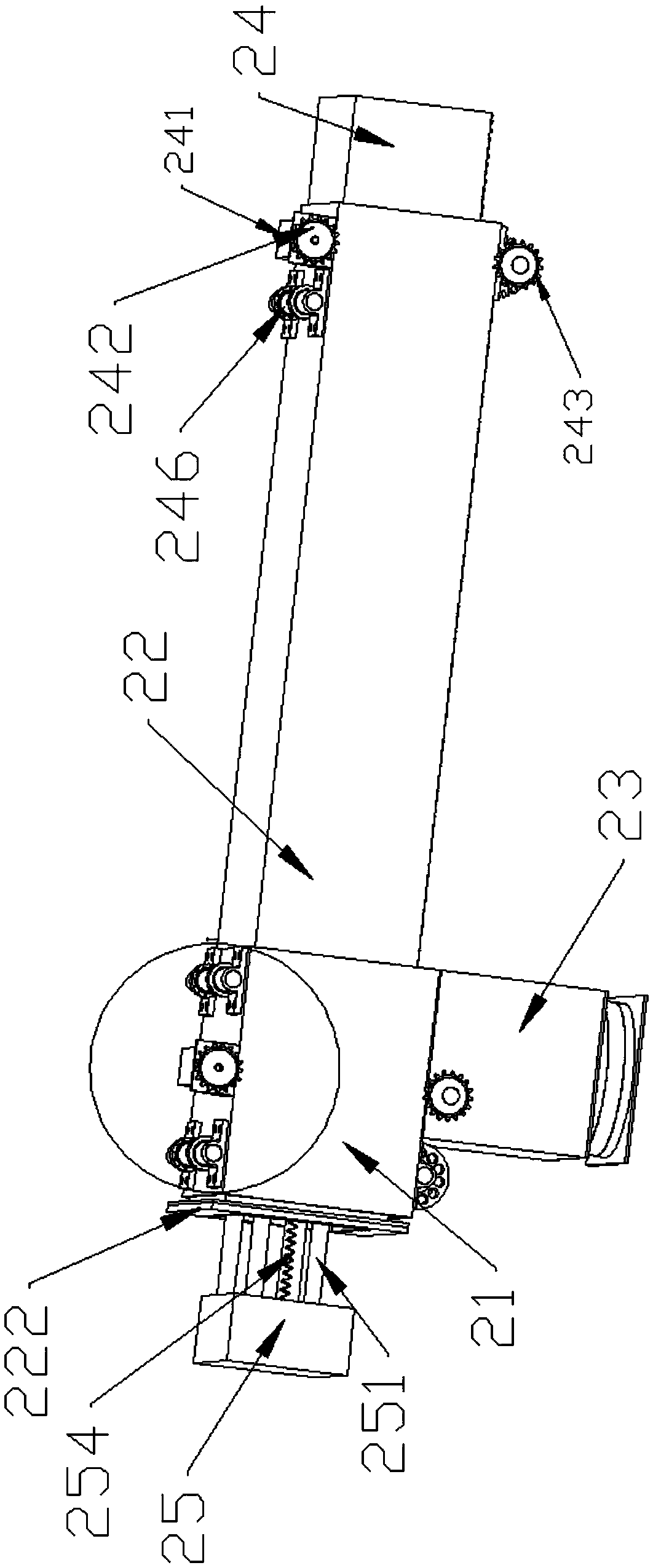

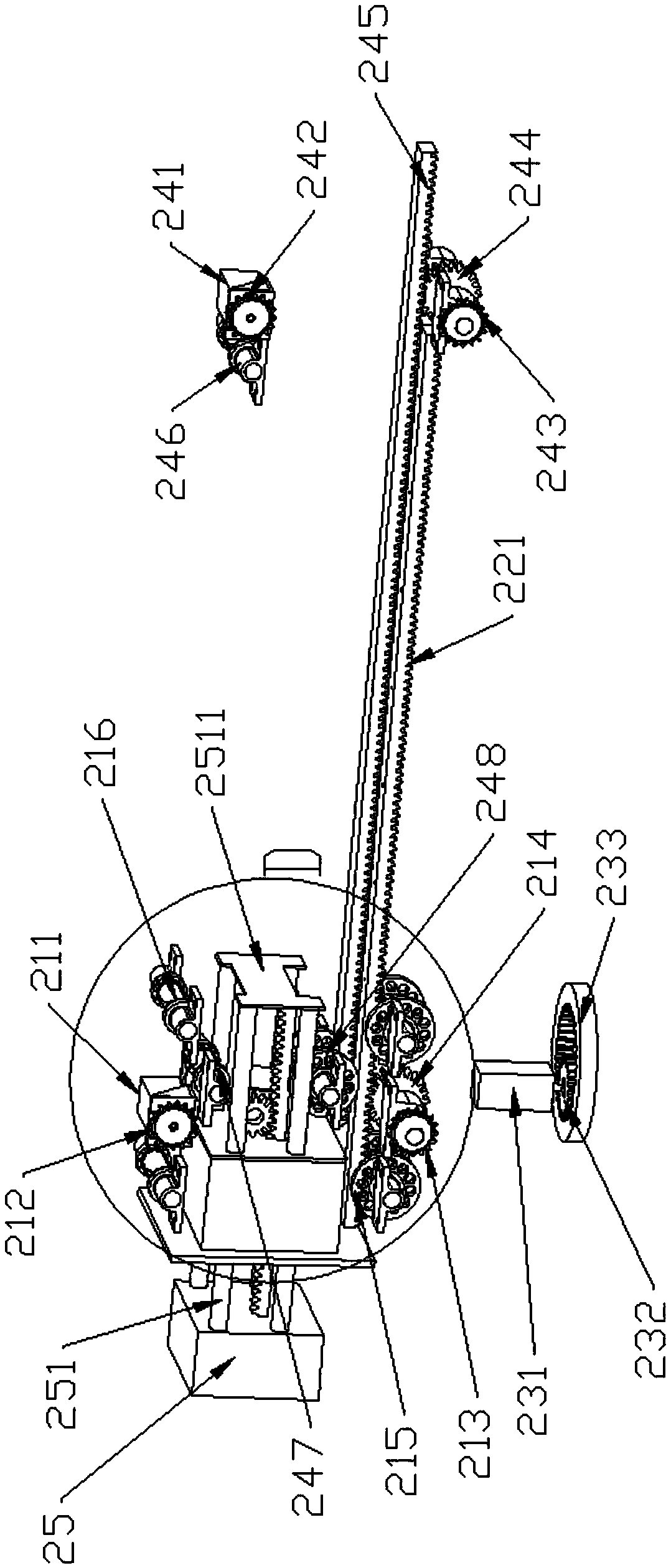

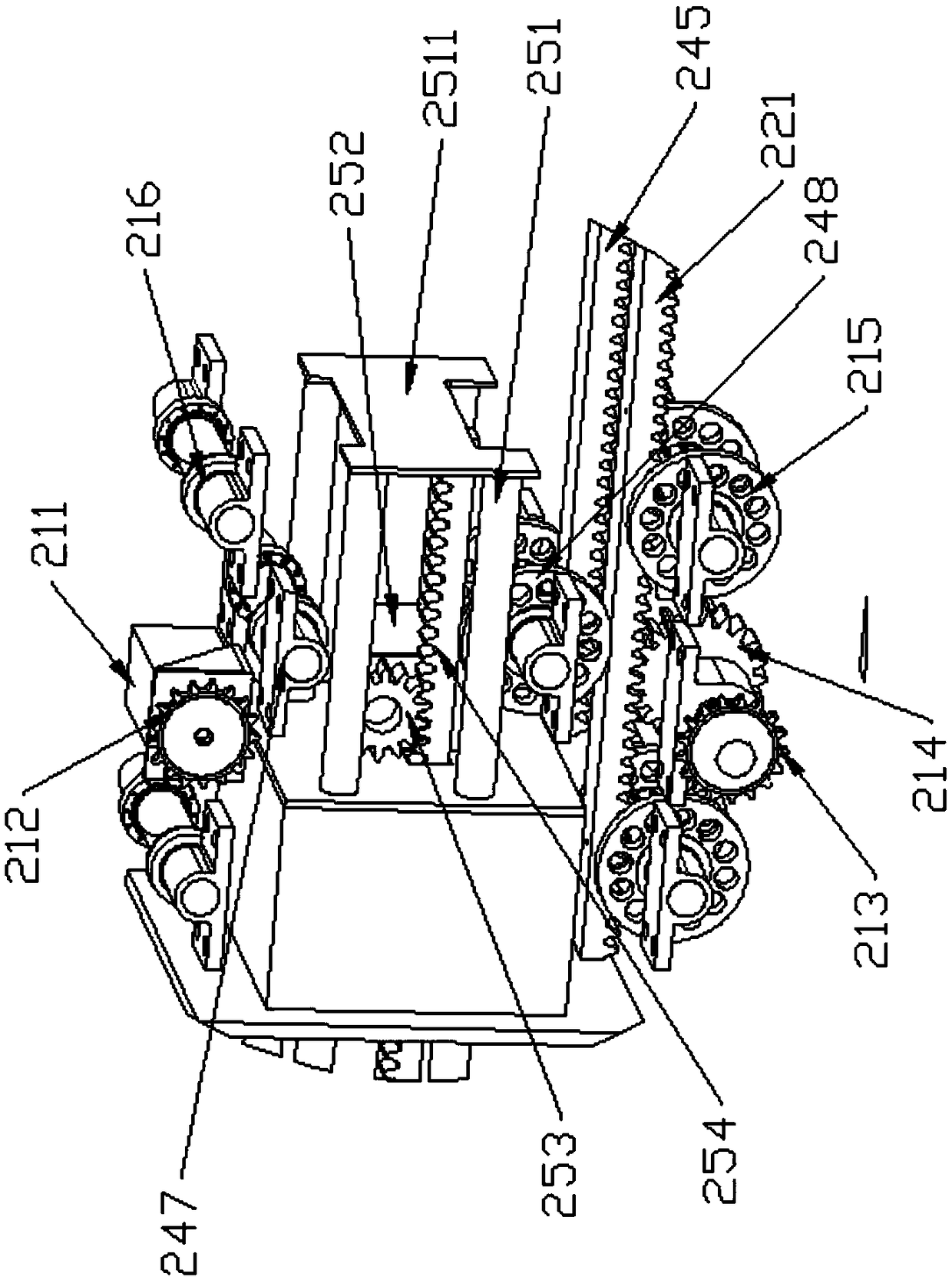

[0037] Embodiment 2: It includes a telescopic arm 22, a support tube 21 sleeved on the outer ring of the telescopic arm 22, the support tube 21 is fixed on the mast, the telescopic arm 22 and the support tube 21 are slidably connected along the axis of the telescopic arm 22, and the outside of the support tube 21 is The lower end of the lower end is fixed with a driven gear 233, and a driving gear 232 is arranged to mesh with the driven gear 233. The driving gear 232 is driven by a rotating motor 231 fixed on the mast, and the two sides of the telescopic arm 22 are provided with telescopic chains to support Both sides of the pipe 21 are provided with telescopic sprockets, and the telescopic motor fixed on the support pipe 21 drives the telescopic sprocket to rotate. The gear 232 drives the driven gear 233 to rotate. This structure is simpler, and many parts are fixed externally to improve assembly efficiency.

[0038] In the actual working process, the rotating motor 231 is dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com