Steering mechanism with two sets of tapered roller bearings

A technology of tapered roller bearing and steering mechanism, applied in steering mechanism, steering rod, mechanical equipment, etc., can solve the problems of acceleration kingpin, easy softening of winding bearing, easy breaking of balls, etc., to improve fatigue resistance and impact ability , Increase the service life and effect, and fix the effect to avoid the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A preferred embodiment of a steering mechanism with double sets of tapered roller bearings of the present invention will be described in detail below in conjunction with the accompanying drawings.

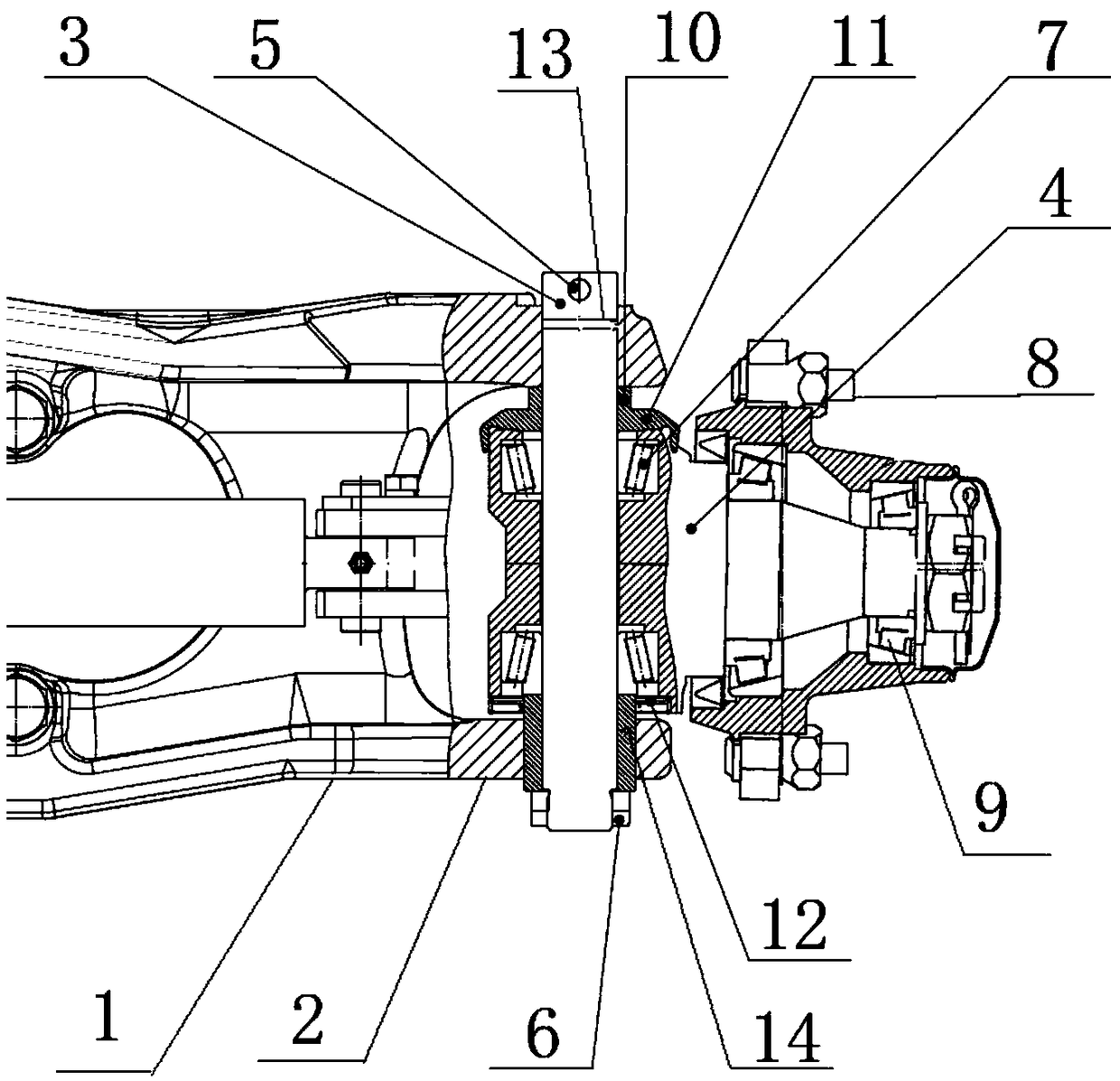

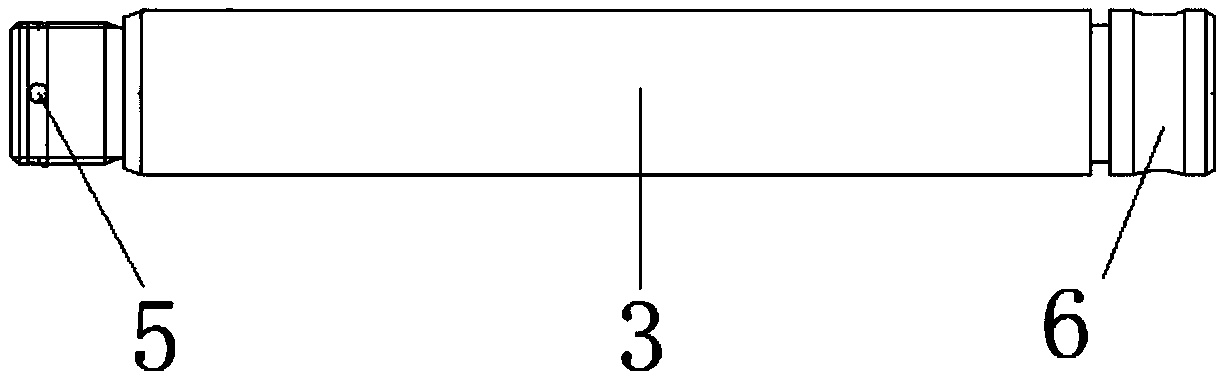

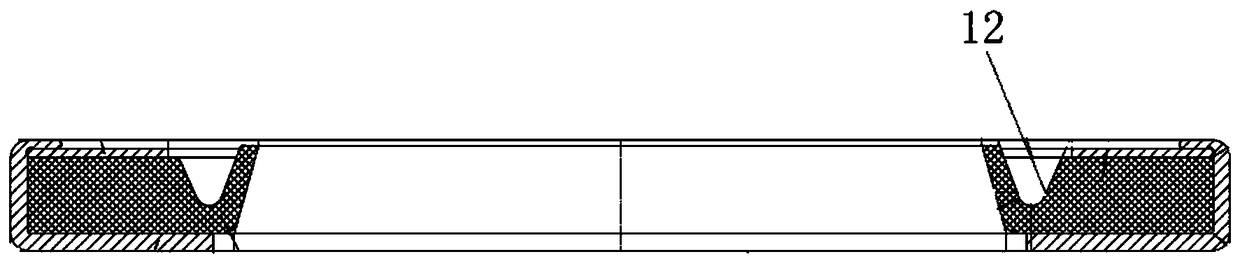

[0022] Such as figure 1 , figure 2 and image 3 As shown, a steering mechanism with double sets of tapered roller bearings includes a steering axle 1, a mounting ring seat 2 at both axial ends of the steering axle, a kingpin 3 arranged in the mounting ring seat, and a kingpin arranged outside the kingpin The steering knuckle 4 with a hollow mounting rod on the circular surface, both ends of the kingpin are arranged on the mounting ring seat through the grooved pin 5 and the slotted nut 6, and the slotted nut 6 is used to extend the kingpin on the outer ring of the mounting ring seat 2 Tighten at the position, and use the grooved pin 5 on the kingpin combined with the pin rod to fix the slotted nut 6, increase the fixing effect of the kingpin while avoiding wear and tear c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com