Horizontal mast assembly

A horizontal and assembly technology, which is applied in the field of horizontal gantry assembly, can solve problems such as easy misalignment and slipping of goods, interference with wheels, safety accidents, etc., and achieves the effect of wide application range and reducing vehicle overturning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Front, rear, left and right in the description of the present invention are the same as the meanings of front, rear, left and right in the field of ordinary automobiles. Specifically, "front" refers to the direction of the cab of the car part of the special vehicle in the longitudinal direction; "rear" refers to the direction in which the vehicle is away from the cab of the car part in the longitudinal direction; Left and right directions when facing the cab of the car part.

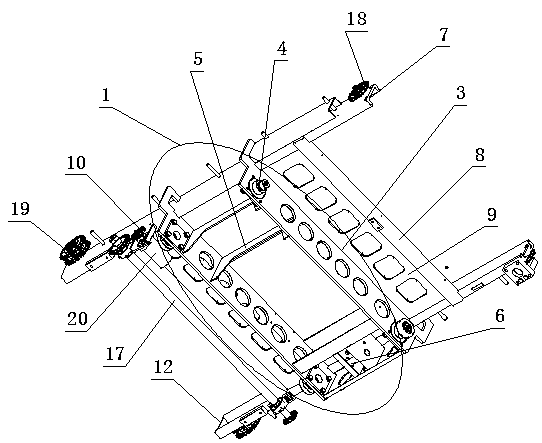

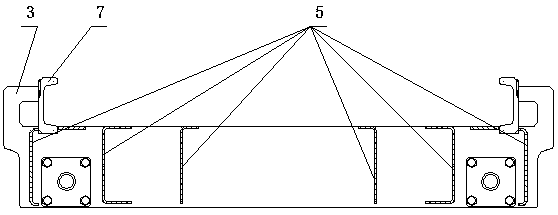

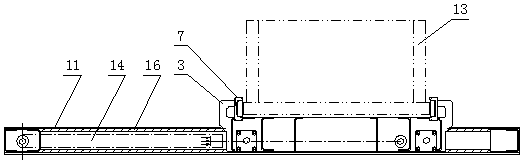

[0024] The horizontal gantry assembly is composed of a longitudinal roller frame 1 and a transverse guide rail frame 2, and the roller frame 3 of the longitudinal roller frame 1 is welded with a transverse guide rail frame 2; the longitudinal roller frame 1 is composed of a roller frame 3, guide rollers 4 and reinforcement plates 5, the roller frames 3 are vertically symmetrically arranged, and the distance between the roller frames 3 matches the distance between the longitudinal beams 11 of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com