Force-induced discoloring asphalt material for asphalt pavement in tunnel and preparation method thereof

A technology of asphalt materials and asphalt pavement, which is applied to building insulation materials, building components, buildings, etc., can solve the problems of short duration and poor luminous efficiency, and achieve the effects of long time, high luminous intensity and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Select 100 parts of heavy traffic road asphalt AH-70 decolorized asphalt and heat it to a fluid state at 100°C, add 10 parts of force-sensing material and 10 parts of reinforcing agent under stirring conditions (speed 200rpm), and stir for 40 minutes to obtain mechanochromic asphalt materials, stored for later use.

[0029] When mixing, heat the mesochromic asphalt material to 170°C, heat the stone material graded as AC-13 to 155°C, and then mix the asphalt and stone material; during construction, spread the mixed asphalt and stone material on the road surface On, control the temperature at 140°C for compaction treatment.

Embodiment 2

[0031] Select 100 parts of heavy traffic road asphalt AH-90 decolorized asphalt and heat it to a fluid state at 100°C, add 5 parts of force-sensing material and 5 parts of reinforcing agent under stirring conditions (speed 100rpm), and stir for 20 minutes to obtain mechanochromic asphalt materials, stored for later use.

[0032] When mixing, heat the mesochromic asphalt material to 150°C, heat the stone material graded as SMA-13 to 155°C, and then mix the asphalt and stone material; during construction, spread the mixed asphalt and stone material on the road surface On, the temperature is controlled at 130°C for compaction treatment.

Embodiment 3

[0034] Select 100 parts of heavy traffic road asphalt AH-90 decolorized asphalt and heat it to a fluid state at 100°C, add 1 part of force-sensing material and 1 part of reinforcing agent under stirring conditions (speed 100rpm), and stir for 20 minutes to obtain mechanochromic asphalt materials, stored for later use.

[0035] When mixing, heat the mesochromic asphalt material to 160°C, heat the stone material graded OGFC-13 to 160°C, and then mix the asphalt and stone material; during construction, spread the mixed asphalt and stone material on the road surface On, control the temperature at 140°C for compaction treatment.

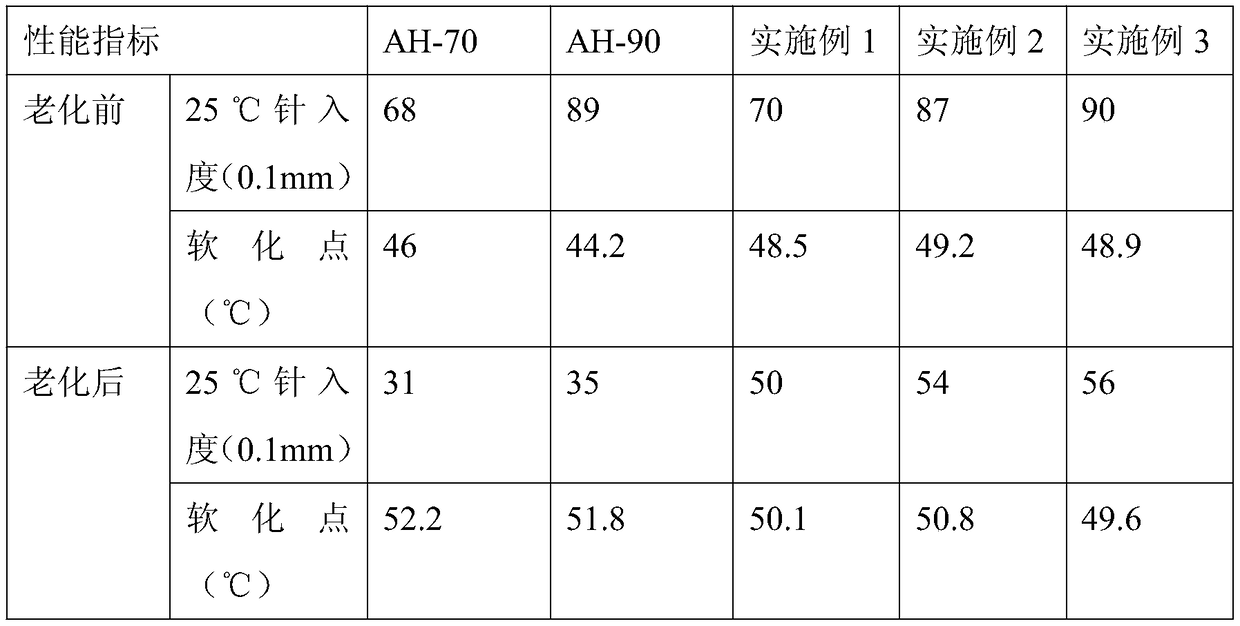

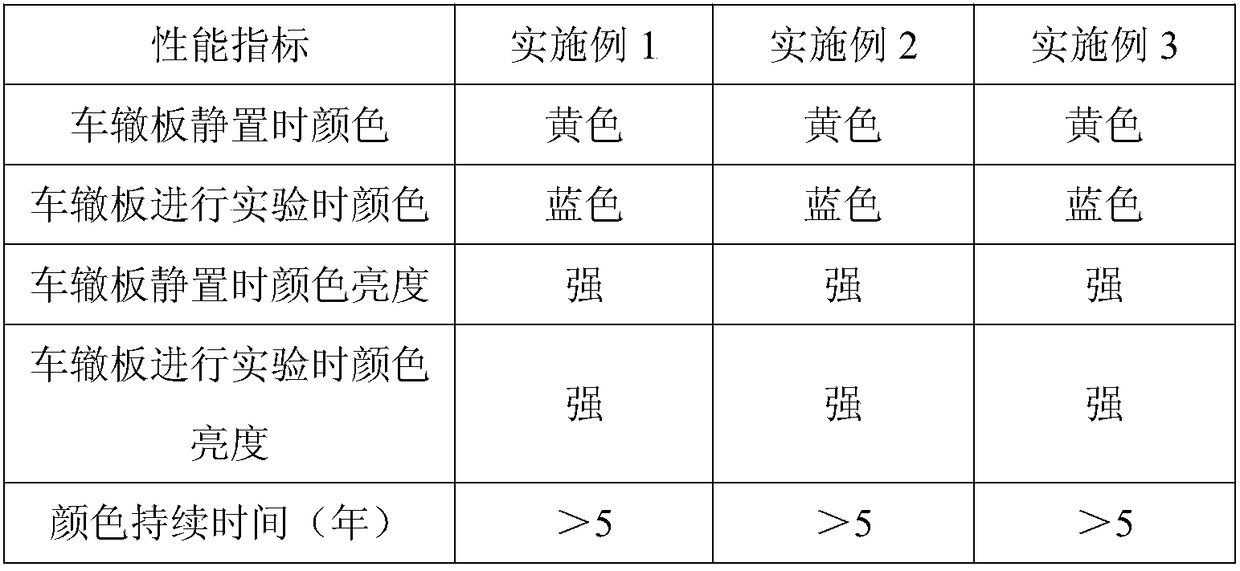

[0036] In the above examples, the comparison between the mechanochromic asphalt material and AH-70 and AH-90 asphalt:

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com