A high softening point oxidized asphalt mixing process

A technology of oxidized asphalt and mixing process, which is applied in the direction of chemical processing of tar pitch/petroleum pitch/natural pitch, chemical/physical/physicochemical process, chemical/physical/physicochemical fixed reactor, etc., which can solve poor circulation , slow discharge speed, waste and other problems, to achieve the effect of reducing residue, reducing floor space and increasing discharge speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

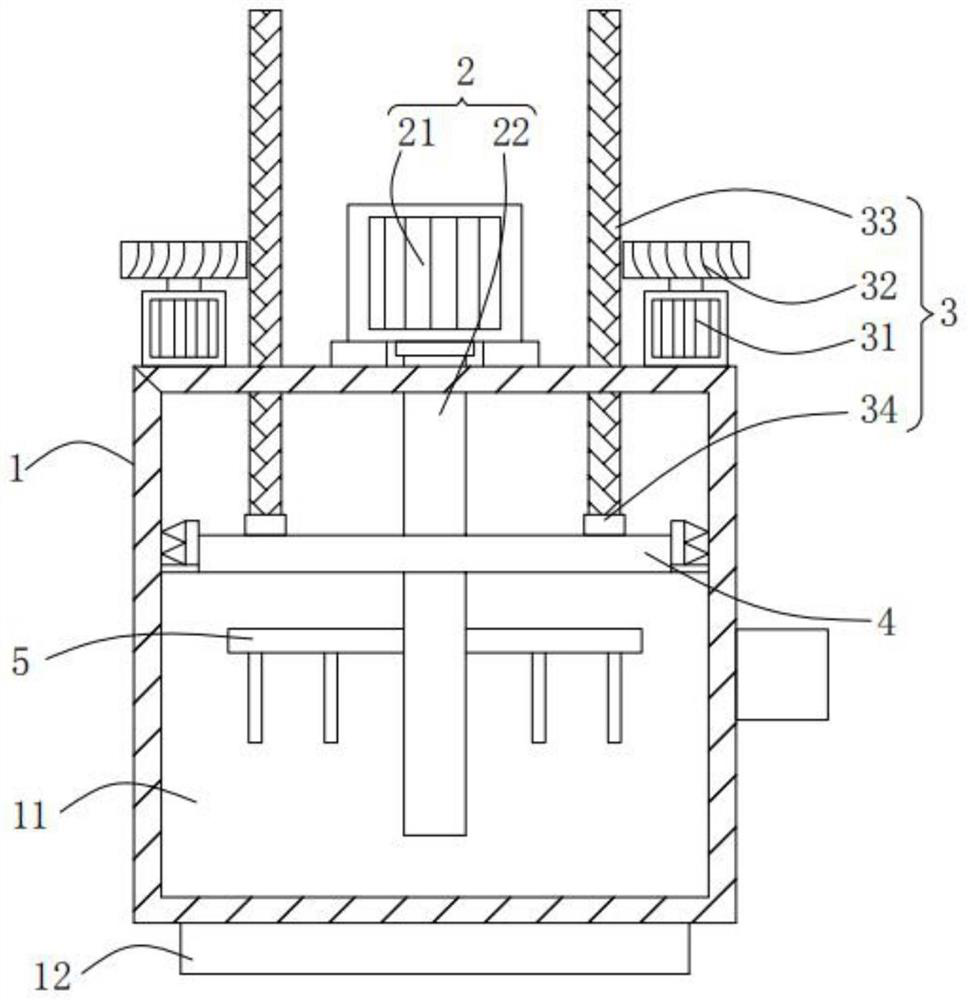

[0034] Such as Figure 1-Figure 7 Shown, a kind of high softening point oxidized asphalt mixing process comprises the following steps:

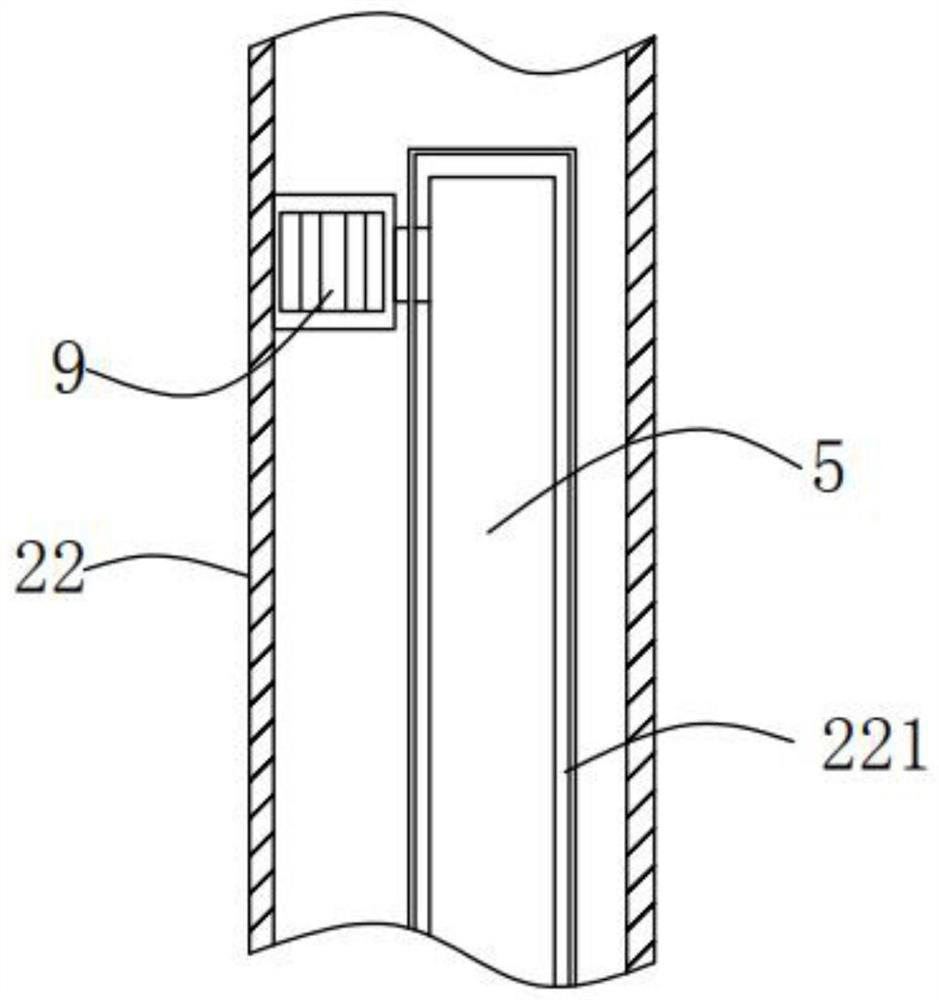

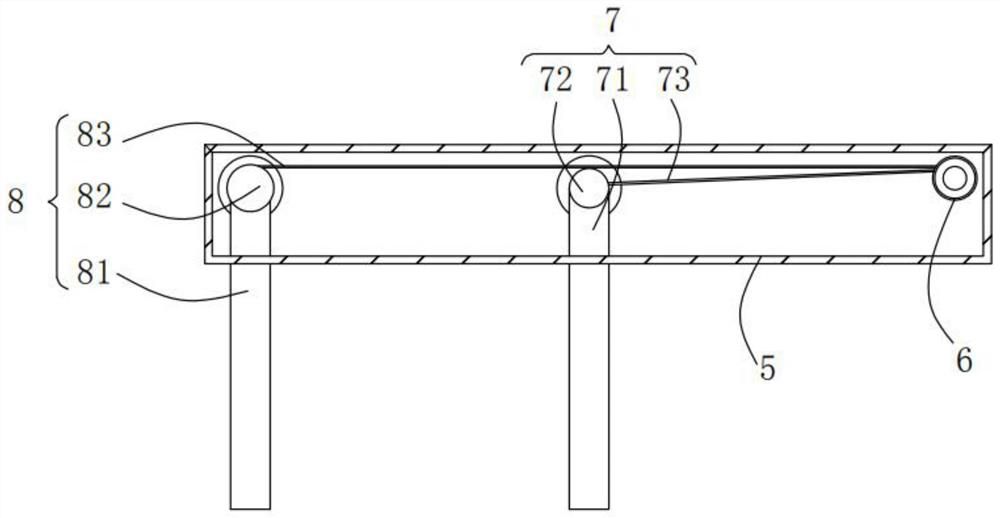

[0035] S1: Asphalt is heated to the preparation temperature in the mixing chamber 11. During the heating and preparation process, the third rotating motor 9 drives the main stirring rod 5 to rotate outward to a vertical state and leave the first storage tank 221. The third rotating motor 9 In the process of driving the main stirring rod 5 to rotate, it will also drive the winding wheel 6 to rotate, and the winding wheel 6 will wind the first traction rope 73 and the second traction rope 83 onto the winding wheel 6, and then drive the winding column 721 to wind around The fixed disk 722 rotates, and the second dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com