Asphalt oxidation treatment process

A technology of asphalt oxidation and treatment process, which is applied in the direction of chemically processing tar asphalt/petroleum asphalt/natural asphalt, etc. It can solve the problems of poor circulation, slow discharge speed, waste, etc., so as to improve the full utilization and reduce the floor space. , The effect of improving the discharge speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

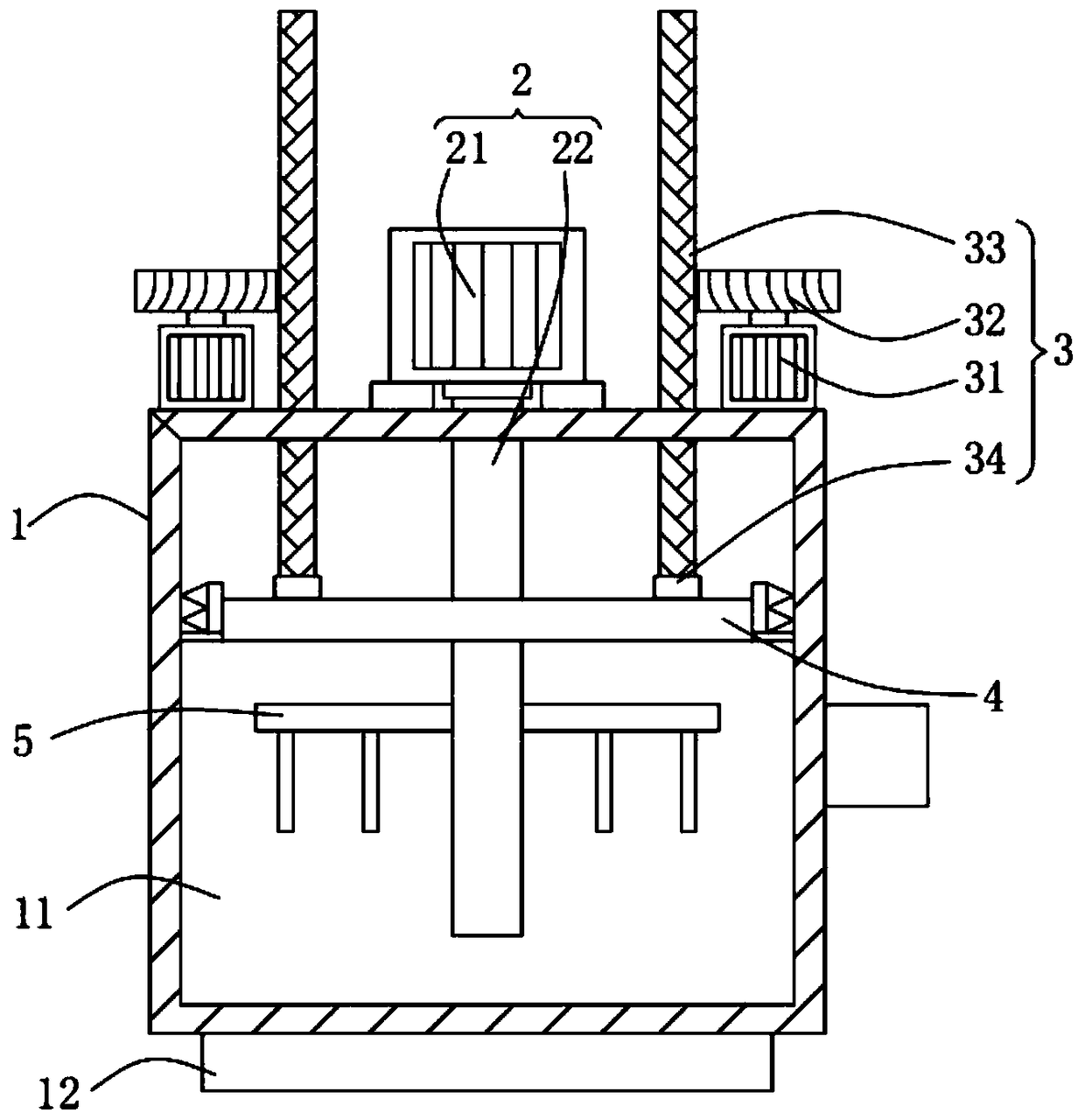

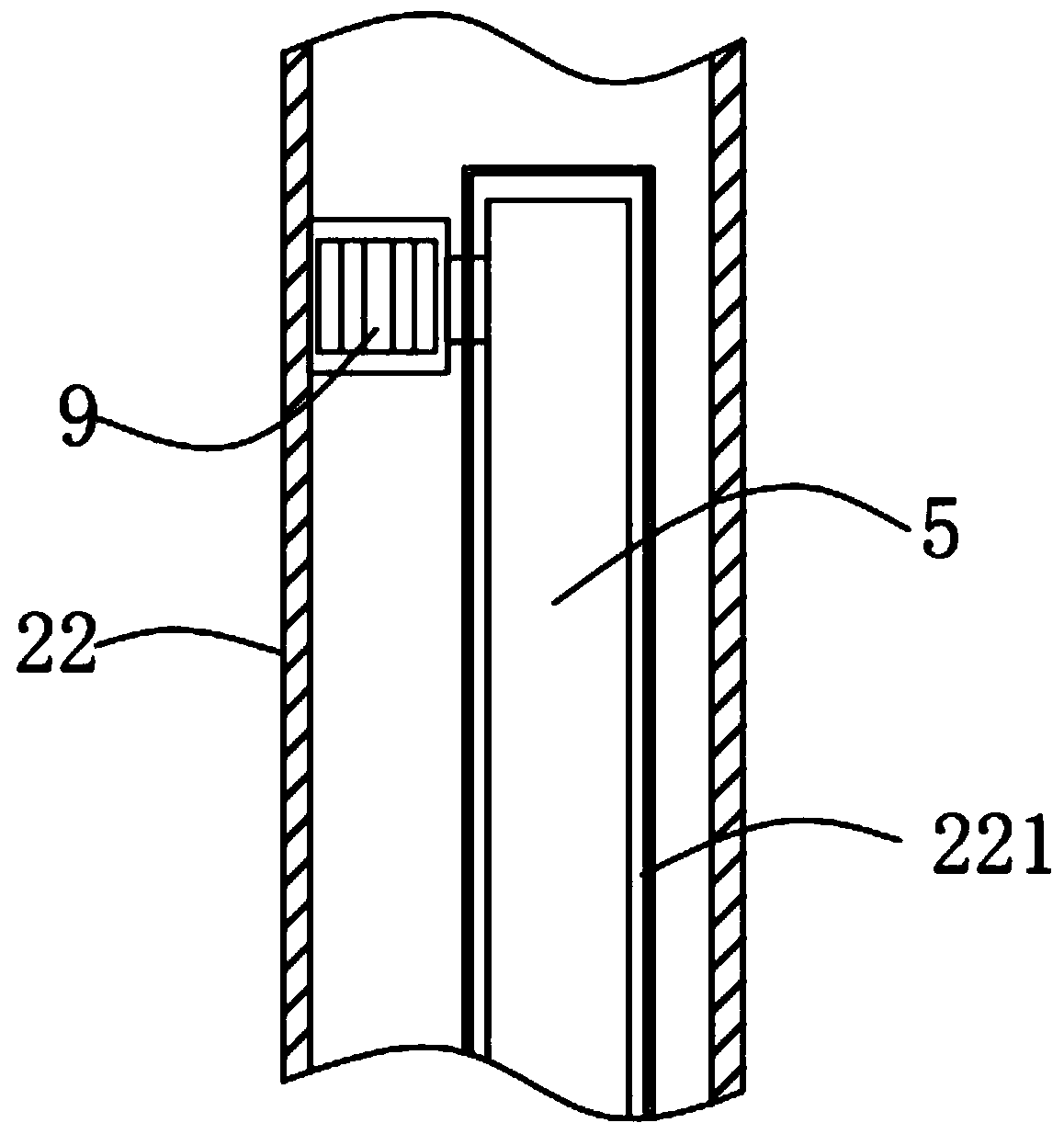

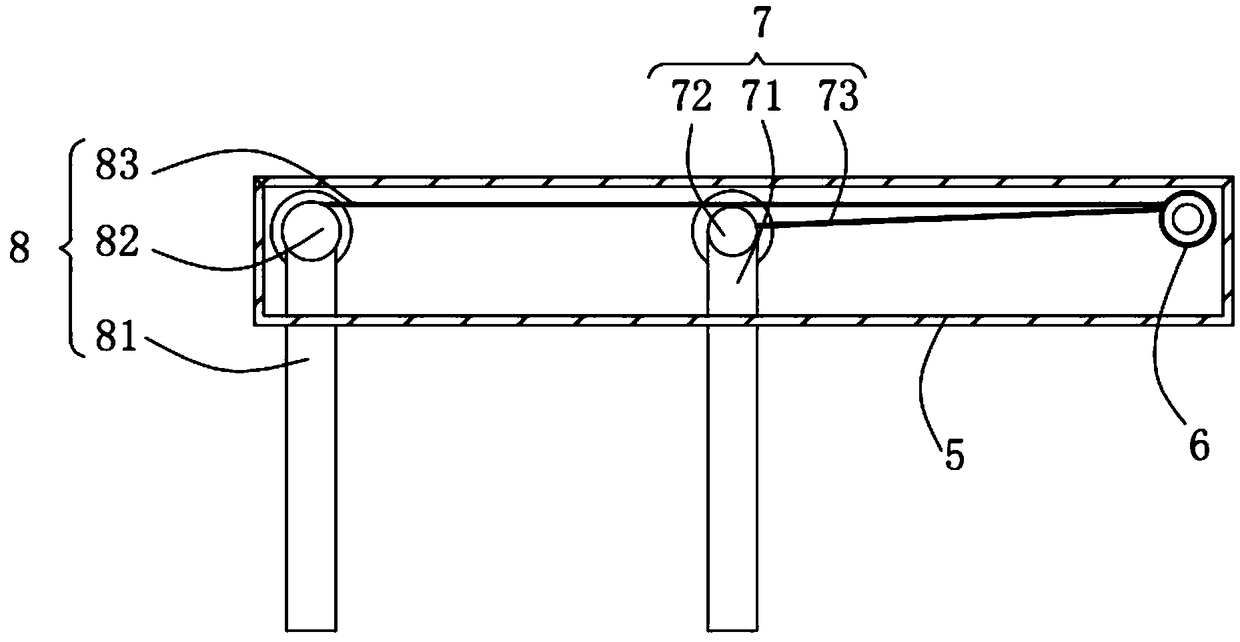

[0032] Such as Figure 1-Figure 7 Shown, a kind of asphalt oxidation treatment process of the present invention, this method comprises the following steps:

[0033] S1, will pass the oxidized bitumen into the bitumen oxidation equipment;

[0034] S2, injecting hot air into the asphalt oxidation equipment in S1, after the asphalt is softened, start the asphalt oxidation equipment to stir the softened asphalt; continuously inject hot air into the asphalt during the stirring process;

[0035] The interior of the asphalt oxidation equipment in S3 and S2 is sealed, and the top of the asphalt oxidation equipment is provided with a pressure valve, and the amount of asphalt added to the asphalt oxidation equipment is 80% of the volume of the asphalt oxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com