Device and method for measuring wear of scraper conveyor sprocket based on focus shape restoration

A scraper conveyor and measuring device technology, applied in measuring devices, optical devices, instruments, etc., can solve problems such as tooth skipping and sprocket tooth breakage, so as to improve operation efficiency, ensure coal mine safety, and realize unmanned operation. The effect of chemical detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

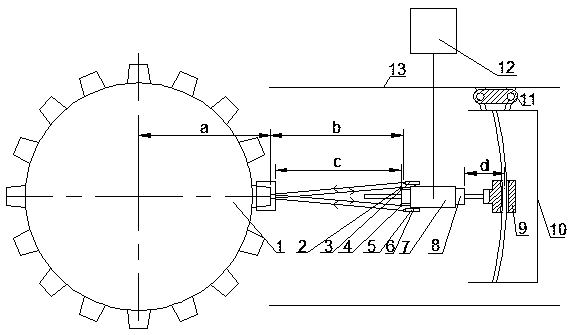

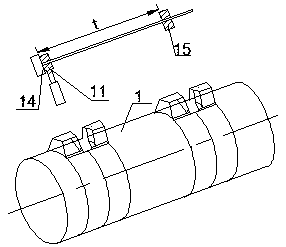

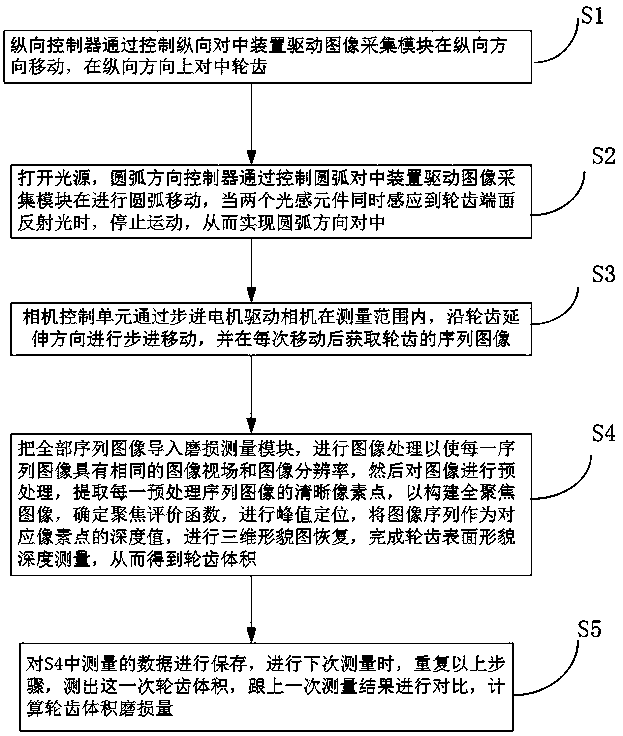

[0024] Such as figure 1 , figure 2 As shown, the present invention is a scraper conveyor sprocket wear measurement device based on focus profile recovery. The sprocket 1 is provided with two rings of gear teeth, including an image acquisition device 10, a longitudinal centering device 11, and an arc centering device. Device 9, wear measurement module 12;

[0025] The longitudinal centering device 11 moves longitudinally so that the image acquisition device 10 centers the gear teeth in the longitudinal direction, and the arc centering device 9 drives the image acquisition device 10 to make an equidistant circular arc movement along the sprocket 1 so that the image acquisition device 10 aligns in the arc direction. For the middle gear tooth, the image acquisition device 10 is facing the end face of the detected gear tooth and gradually approaches and collects the gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com