Car trunk seal ring matching surface detection device and method based on real working condition simulation

A technology of working condition simulation and sealing ring, which is applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, etc., can solve the problem of difficult control of the assembly size of the matching surface of the tailgate sealing ring, reduced detection reliability, and difficulty in rapid detection, etc. problems, to achieve the effect of reducing man-hours, improving detection accuracy, and saving enterprise costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be pointed out that the technical solution and design principles of the present invention will be described in detail below only with an optimized technical solution, but the protection scope of the present invention does not limited to this.

[0022] The described embodiment is a preferred implementation of the present invention, but the present invention is not limited to the above-mentioned implementation, without departing from the essence of the present invention, any obvious improvement, replacement or modification that those skilled in the art can make Modifications all belong to the protection scope of the present invention.

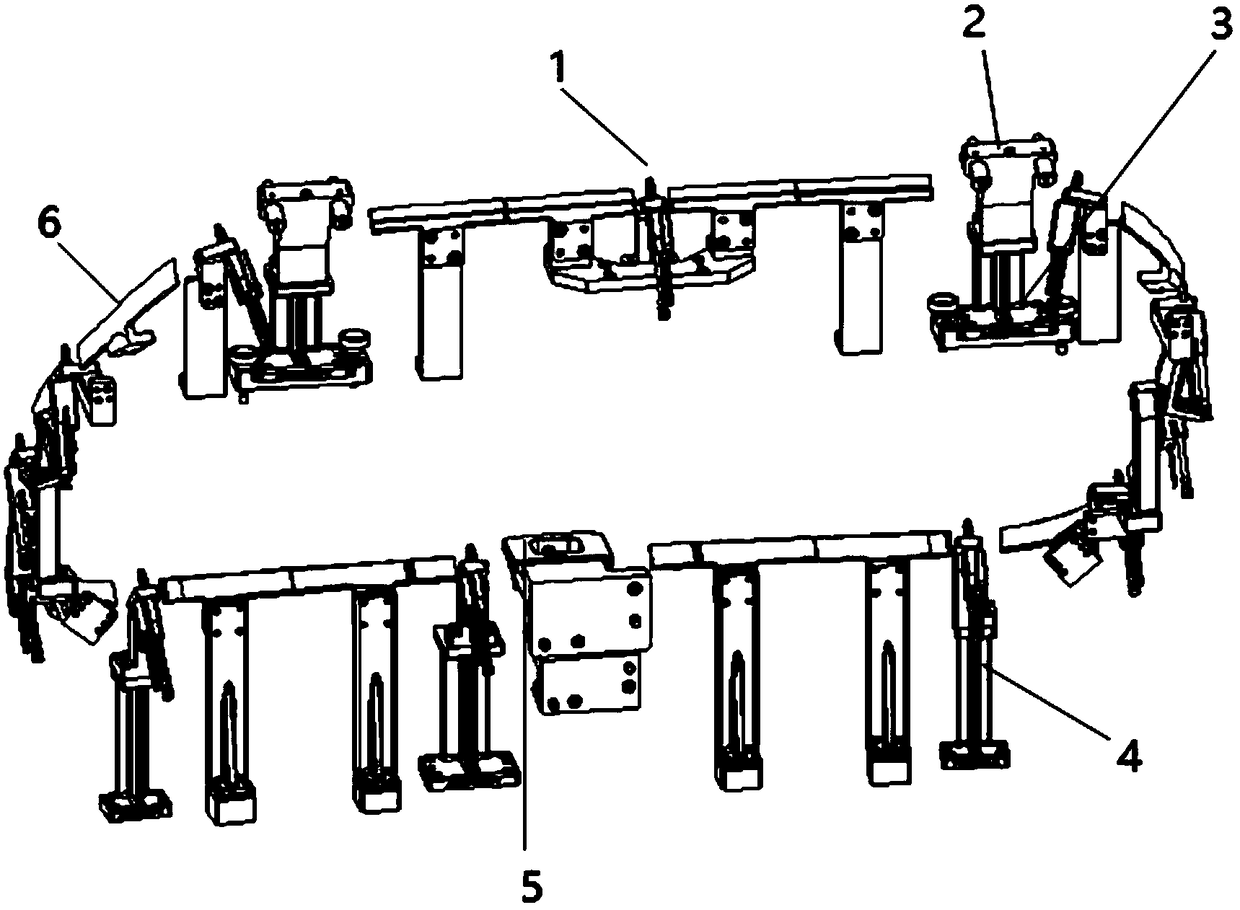

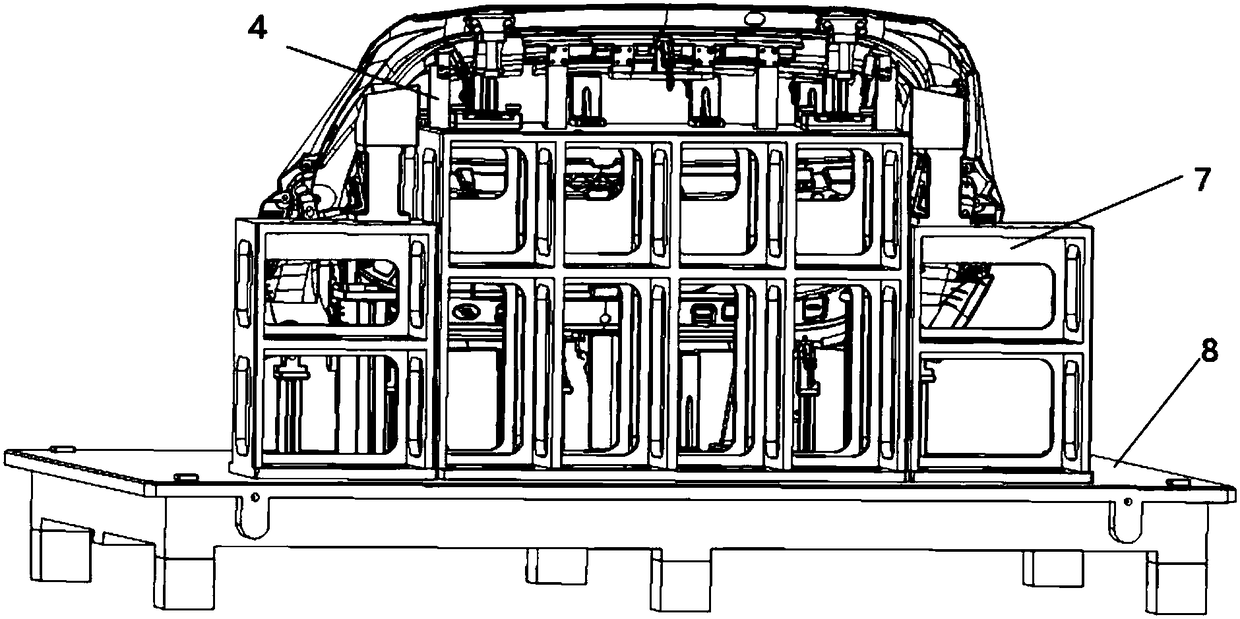

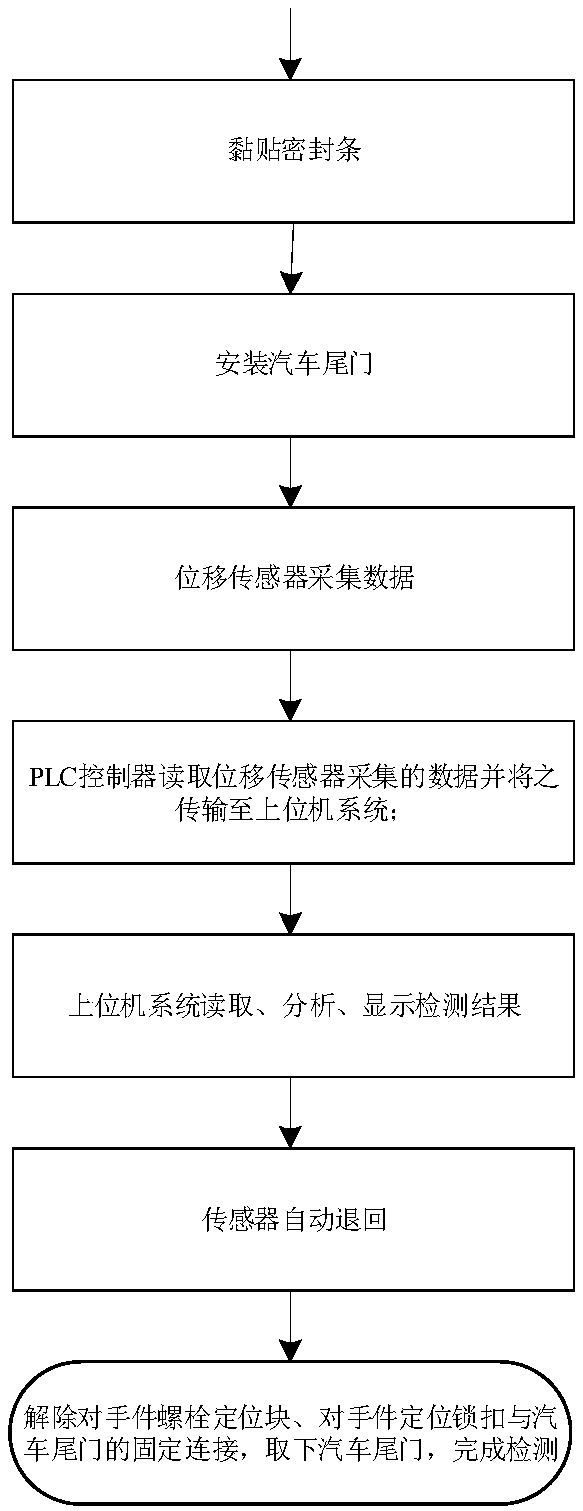

[0023] like figure 1 , figure 2 As shown, the vehicle tailgate sealing ring matching surface detection device for actual working conditions simulation of the present invention is composed of a frame mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com