An adaptive multi-step variable domain optimization method for solder joint layout of automotive components based on topology optimization

A technology of topology optimization and layout optimization, applied in design optimization/simulation, special data processing applications, geometric CAD, etc., can solve problems such as the inability to simultaneously optimize the number of solder joints and the layout of solder joints, so as to ensure rationality and improve accuracy sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

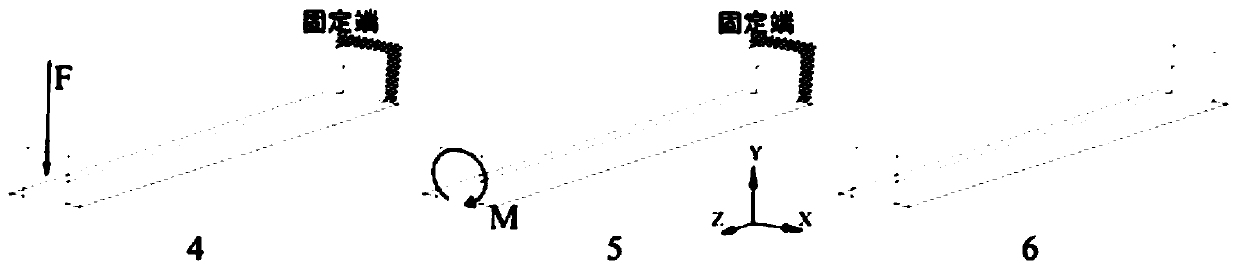

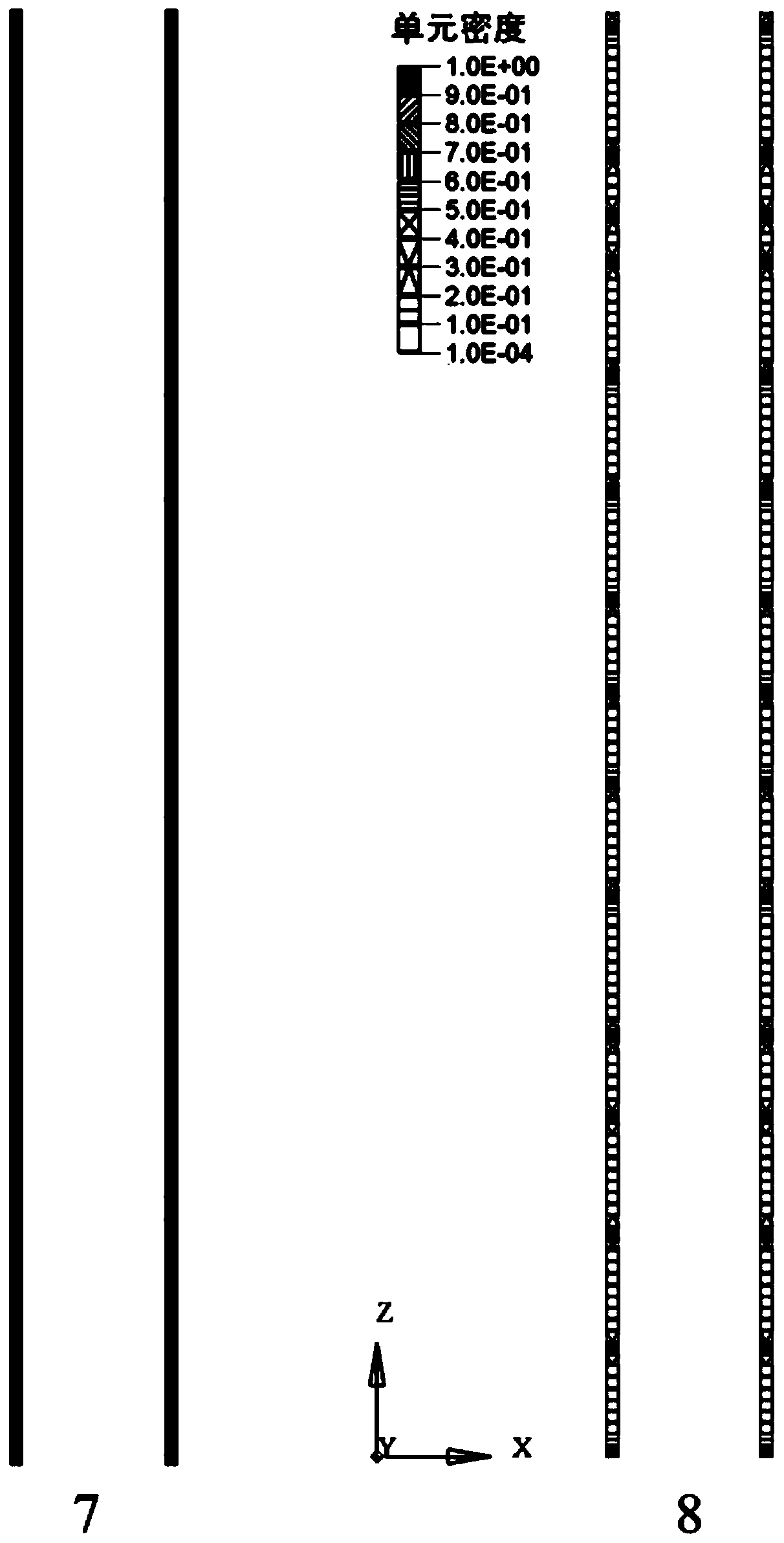

[0094] This embodiment provides a topology optimization-based self-adaptive multi-step variable domain welding spot layout optimization method for automotive components, and describes the specific implementation of the present invention in detail in conjunction with the accompanying drawings and technical solutions. The number and arrangement of solder joints have a direct impact on manufacturing cost and structural performance. The purpose of solder joint optimization is to avoid performance defects caused by insufficient solder joints and increase in manufacturing cost and process layout difficulty due to excessive solder joints.

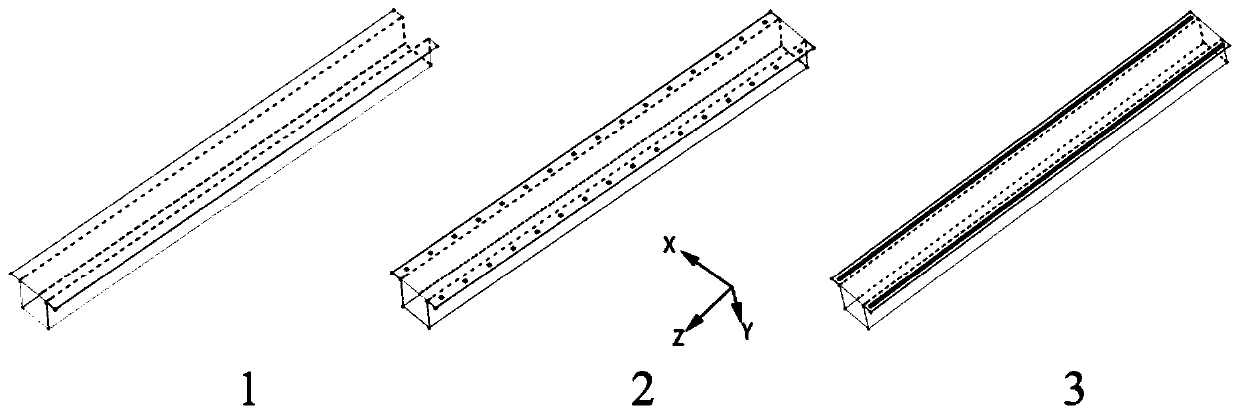

[0095] Aiming at the present solder joint design, it is still difficult to simultaneously optimize the number of solder joints and the arrangement form, and the present invention adopts a continuous solder joint unit, such as figure 1 As shown in 3, instead of the traditional discrete solder joints, the solder joint optimization is converted from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com