Combination comprising a housing and a flange, and assembly

A combined device, flange technology, applied in the direction of pumping device for elastic fluid, valve device, fuel injection device, etc., can solve unsatisfactory problems and achieve the effect of preventing undesired changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

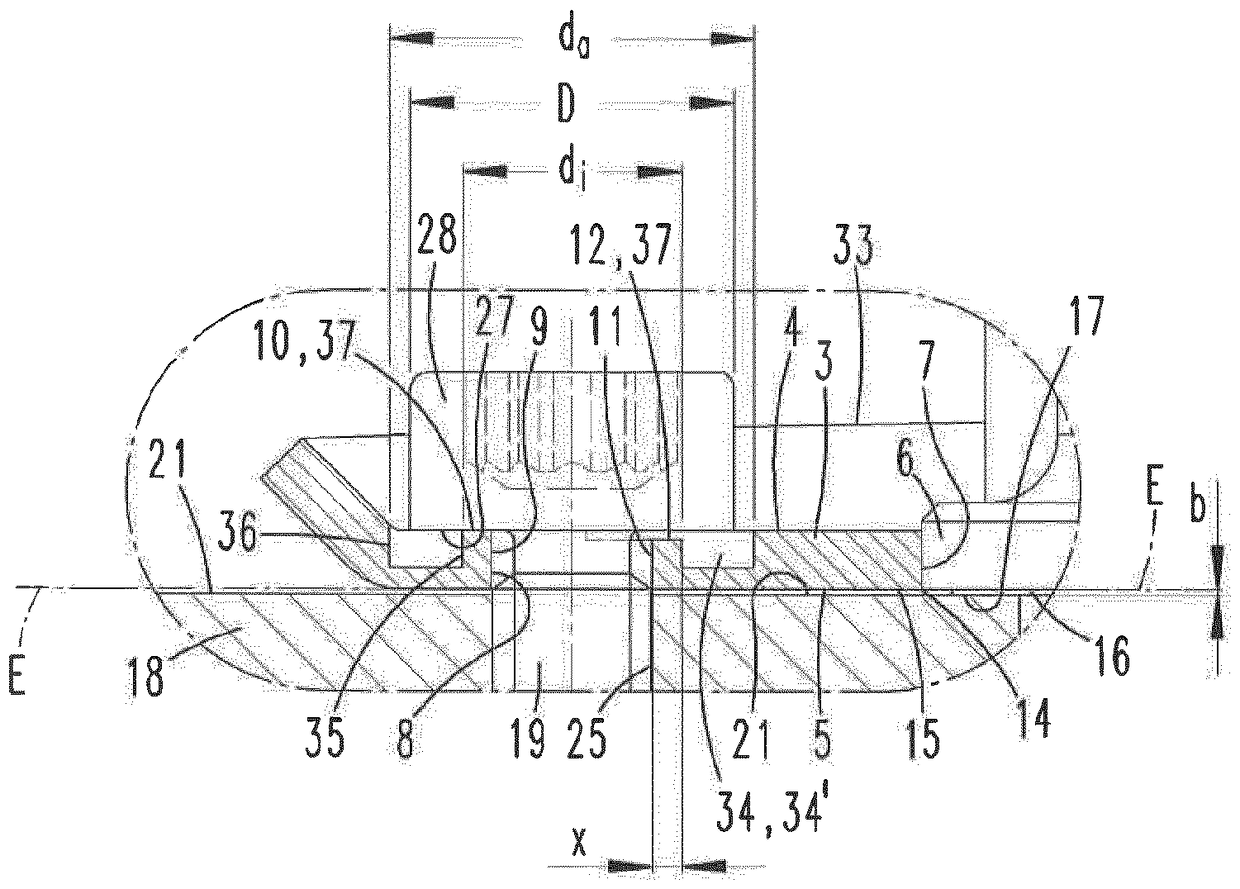

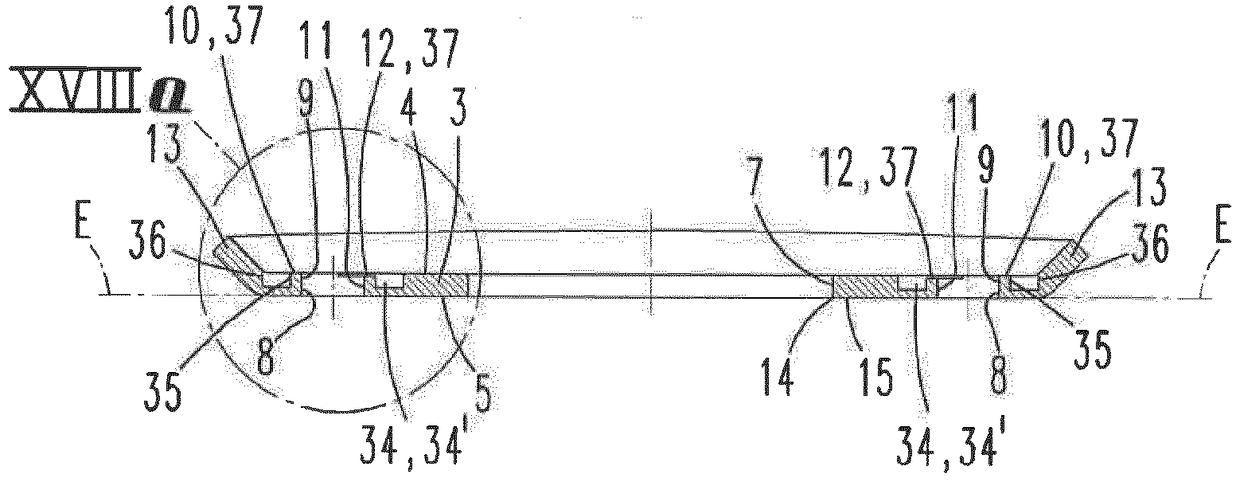

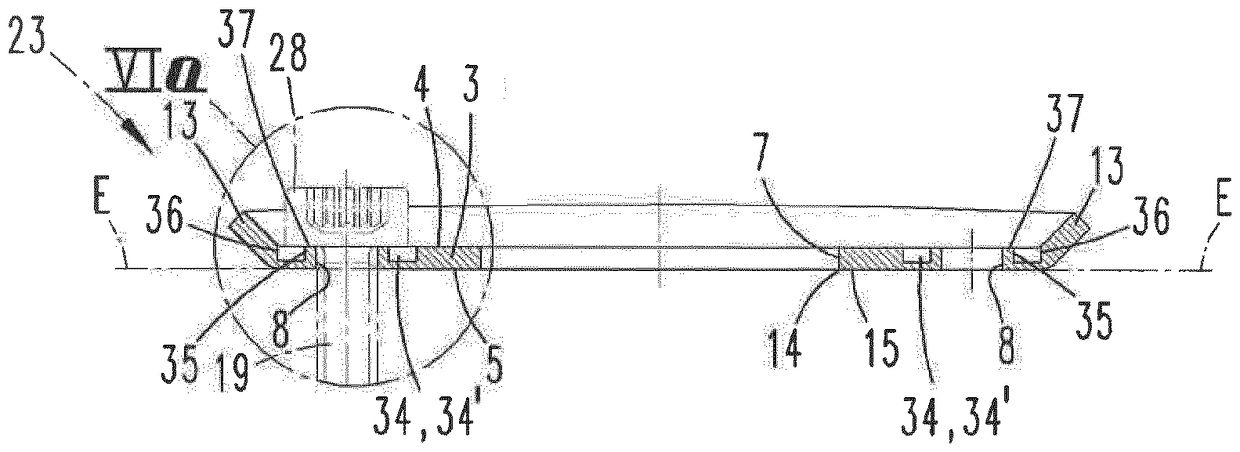

[0055] will refer to Figure 1 to Figure 6a A combined device 1 according to the invention and according to a first exemplary embodiment is presented. The combined device 1 comprises a housing 2 and a flange 3 having a first flange side 4 facing the housing 2 and a second flange side 5 opposite thereto. A collar 6 inserted into a connector opening 7 of the flange 3 is formed on the housing 2 . In this example, the collar 6 is press-fitted into the connector opening 7 by press-fitting, and is additionally fastened to the flange 3 by means of a laser-welded connection (not shown in more detail). Two assembly openings 8 , the latter being through holes like the connector opening 7 , are formed on the flange 3 . For the sake of clarity, the assembly opening 8 and the details described in the context adjacent thereto or therewith are each designated with the same reference signs. Two recesses 34 (where in each case one recess 34 extends in an uninterrupted manner on the circumfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com