Flexible substrate chip-on flex repair

A substrate, linear axis technology, applied in the field of digital radiography detector panels, can solve problems such as damage and difficult replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

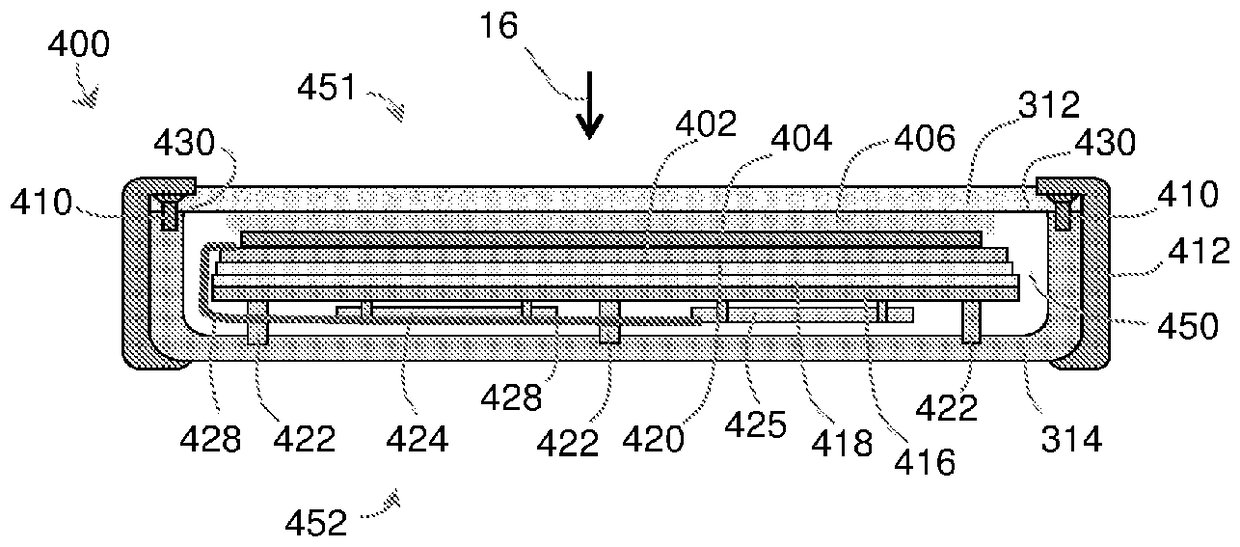

[0024] figure 1 is a perspective view of a digital radiography (DR) imaging system 10 according to one embodiment, which may include a generally curved or planar DR detector 40 (shown in a planar embodiment and without housing for clarity of description) body), x-ray source 14 (which is configured to generate radiographic energy (x-ray radiation)), and digital monitor or electronic display 26 (which is configured to display images captured by DR detector 40). The DR detector 40 may comprise a two-dimensional array 12 of detector cells 22 (photosensors) arranged in electronically addressable rows and columns. DR detector 40 may be positioned to receive x-rays 16 emitted by x-ray source 14 through subject 20 during a radiographic energy exposure or pulse of radiographic energy. Such as figure 1 As shown in , a radiographic imaging system 10 may employ an x-ray source 14 that emits collimated x-rays 16 (eg, an x-ray beam) selectively directed at and through a preselected region...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com