Toner-density calculating method, reflective optical sensor, and image forming apparatus

a toner density and calculating method technology, applied in the direction of electrographic process, electrographic process apparatus, instruments, etc., can solve the problems of difficult to always keep, difficult to calculate toner density, and difficult to see toner image formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0133]Exemplary embodiments of the present invention are described in detail below.

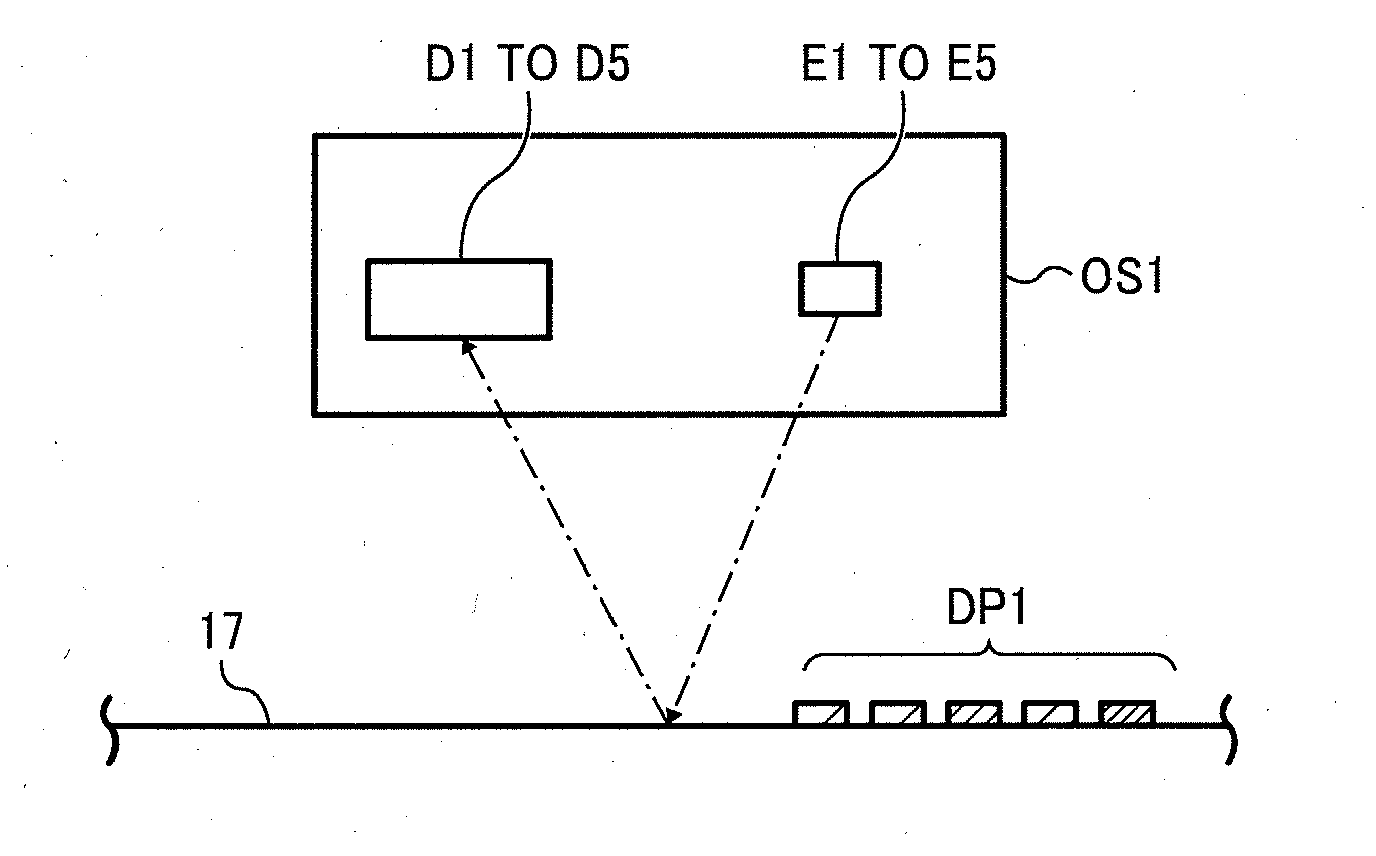

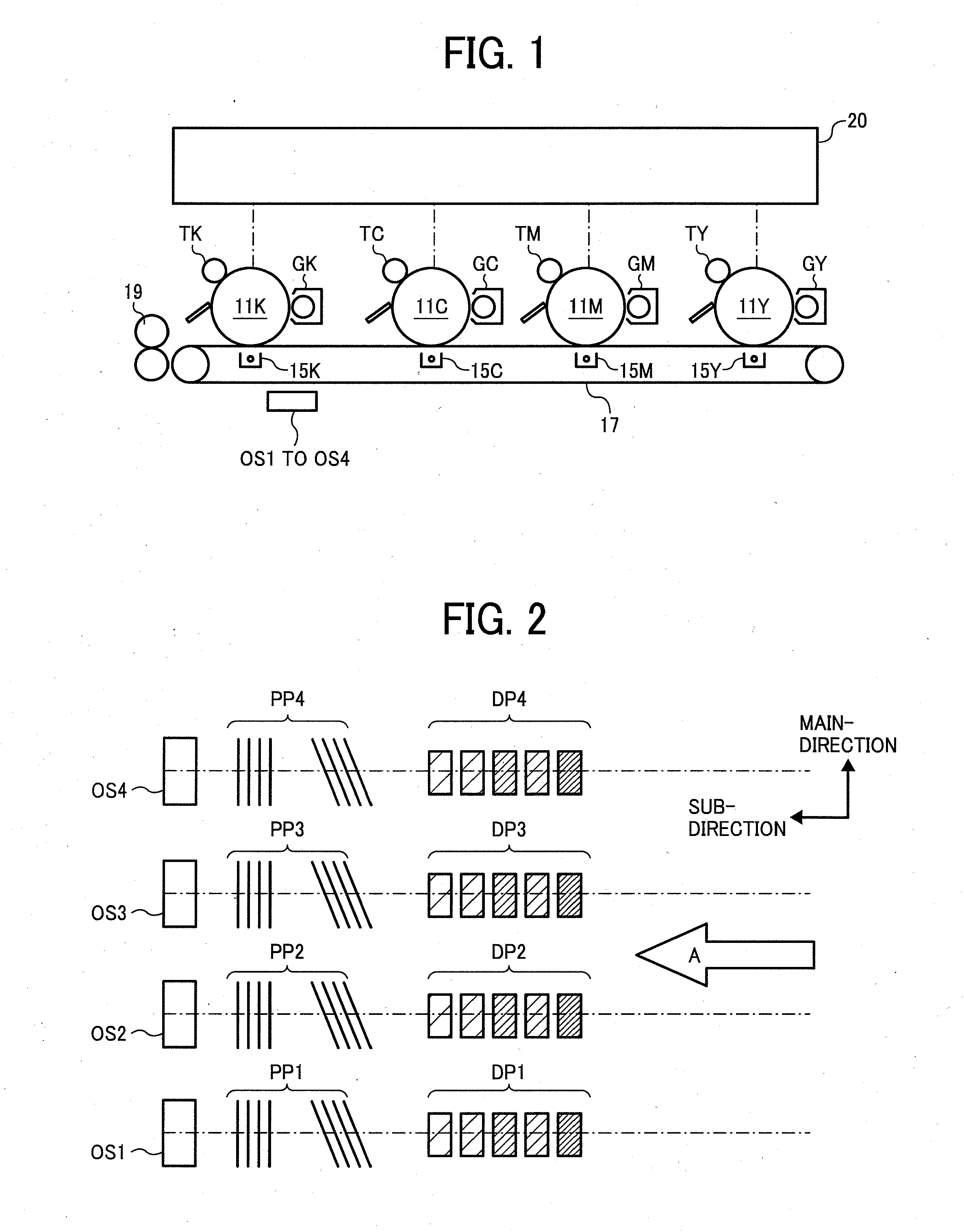

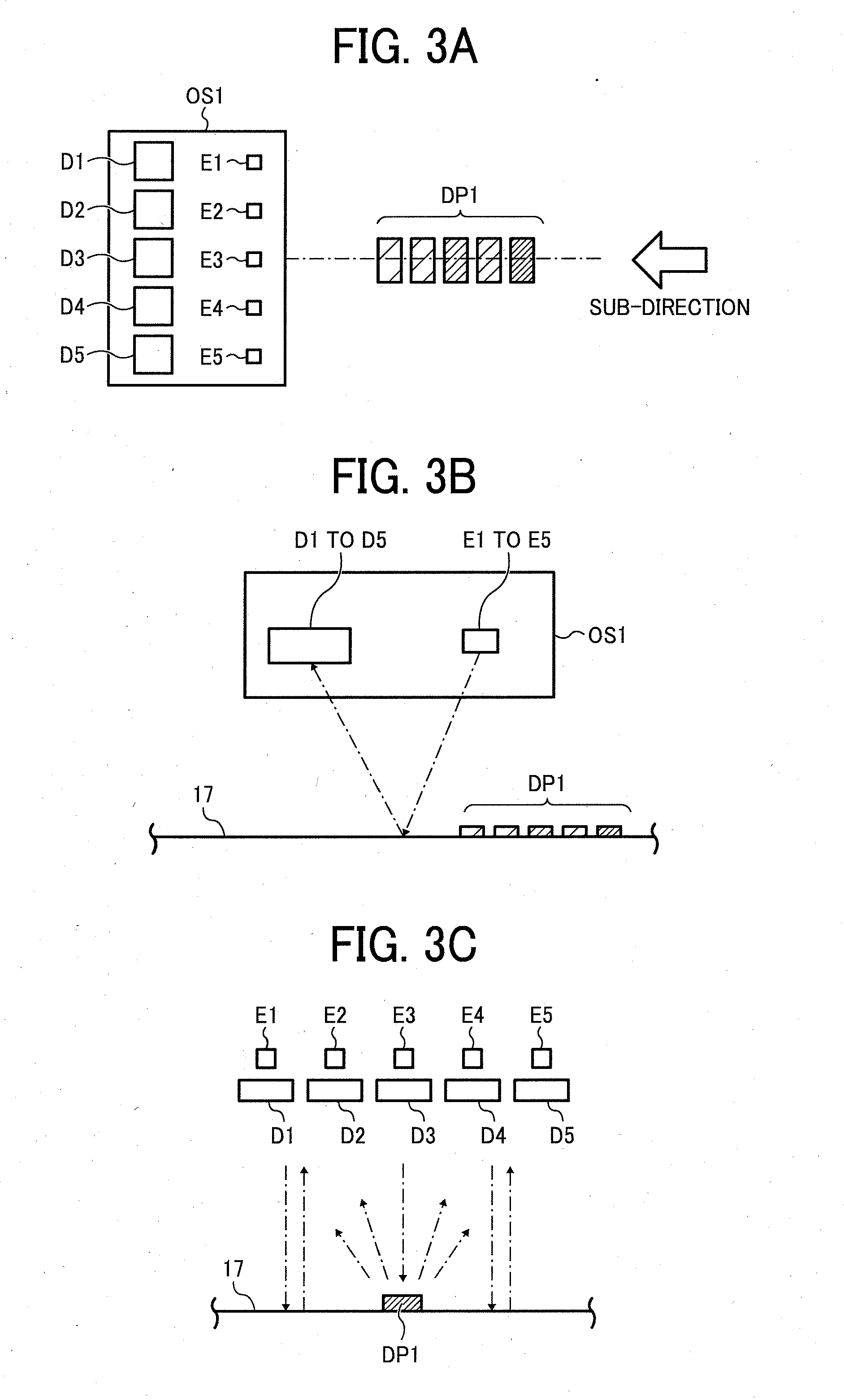

[0134]A density calculating method according to the present embodiment involves, in a method of forming images with toner, forming a predetermined toner pattern on a supporting member moving in a predetermined sub-direction, causing a light-emitting unit to illuminate the supporting member with detection light, receiving the light reflected by the supporting member and / or the toner pattern at a light-receiving unit, and calculating the toner density using difference between characteristics of the supporting member reflecting the detection light and characteristics of the toner pattern reflecting the detection light.

[0135]The method of forming images with toner is used in the copiers, the printers, the plotters, the facsimile machines, the MFPs, etc. The method of forming images with toner includes the process of forming the electrostatic latent image and the process of developing the electrostatic lat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com