Plug contact

A technology of contact parts and contact holes, which is applied in the directions of contact parts, connection, fixed connection, etc., can solve the problems of cost and separation, difficulty in realization, and inability to connect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

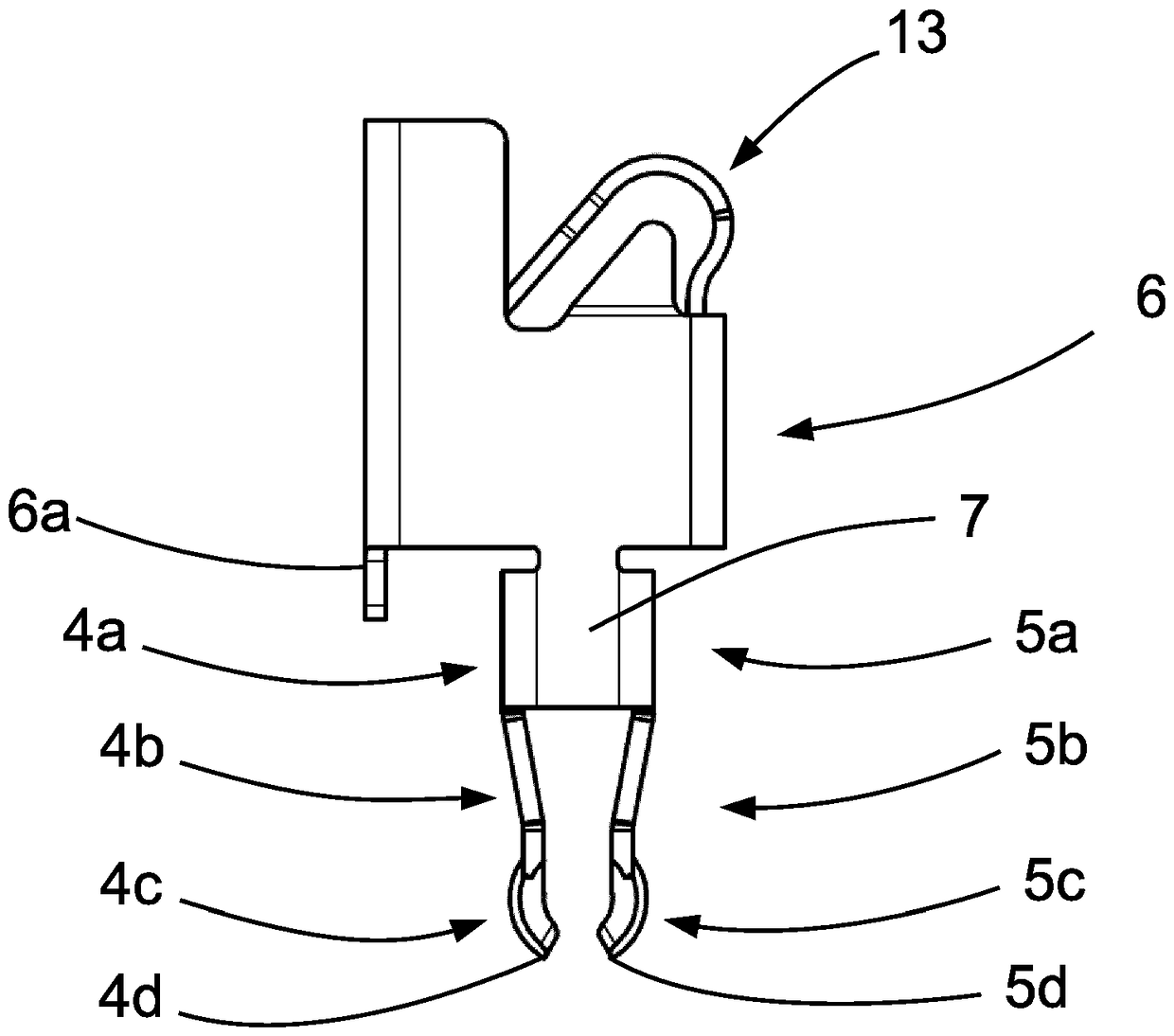

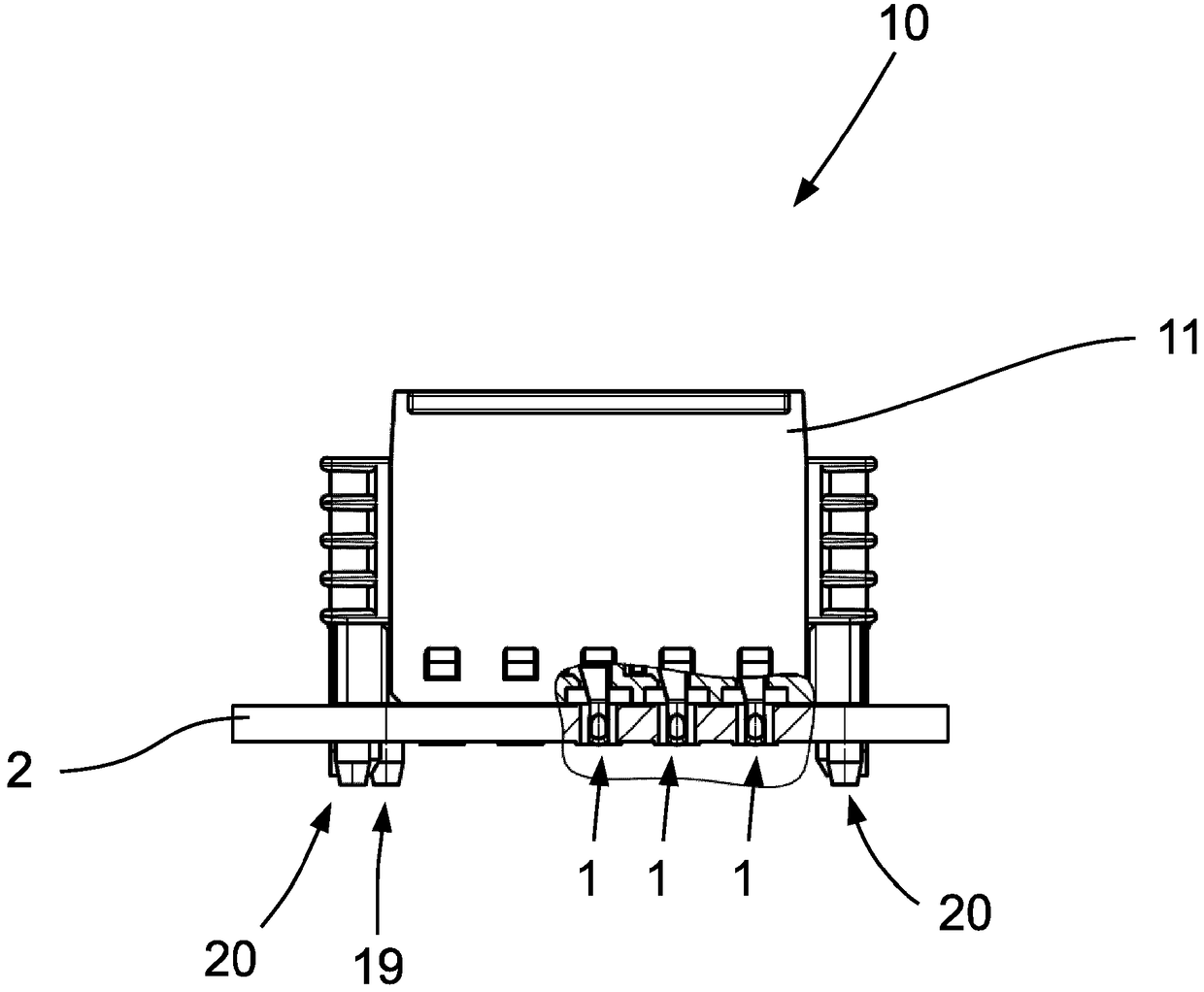

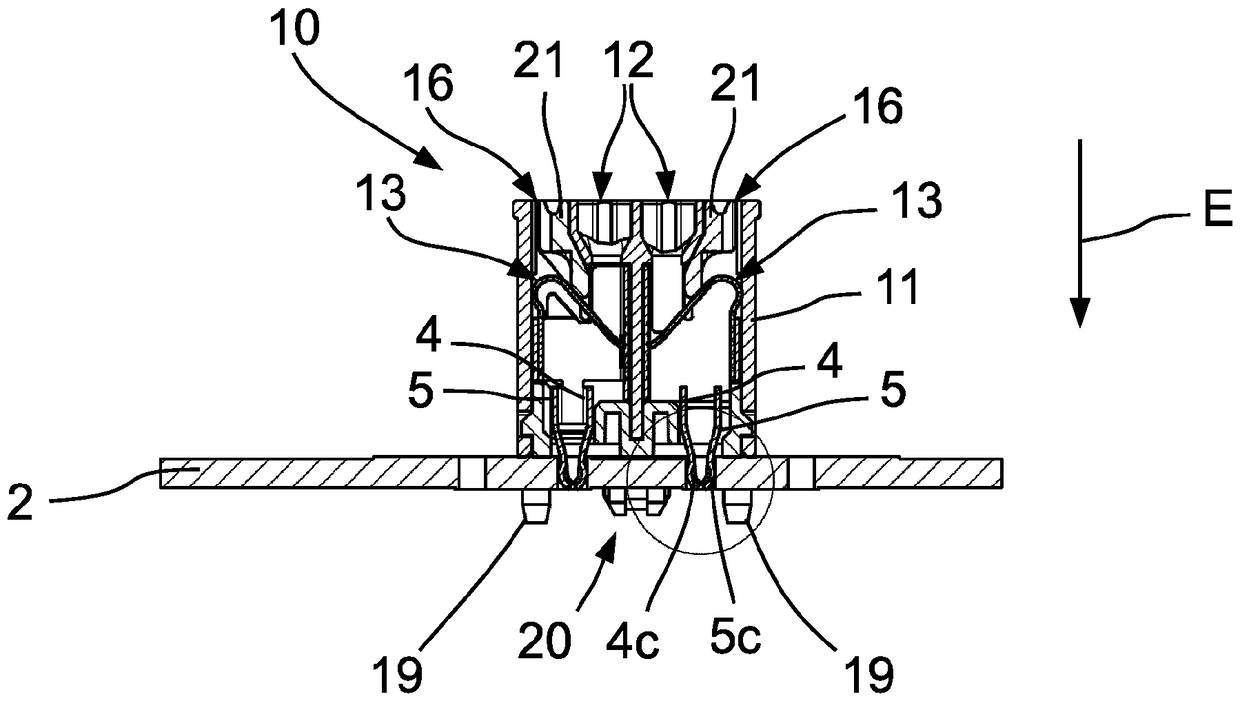

[0034] figure 1 with 2 A preferred embodiment of a plug contact 1 for contacting a circuit board 2 is shown, for which purpose the plug contact 1 is inserted into a corresponding contact hole 3 in the circuit board 2 (see Image 6 with 7 ). The punched and bent plug-in contact 1 from a metallic flat material has two contact legs 4 , 5 that are elastic relative to each other, a contact region 6 and a connection region 7 , wherein the two contact legs 4 , 5 are connected to each other via the connection region 7 . Connected and connected to joint area 6.

[0035] The two contact legs 4 , 5 each have a first section 4 a , 5 a and a second section 4 b , 5 b , which are respectively connected to the first section 4 a , 5 a in the insertion direction E of the plug-in contact 1 . as especially from figure 1 As can be seen, the two contact legs 4 , 5 are bent from the plane of the connecting region 7 , so that the connecting region 7 and the connected first regions 4 a , 5 a of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com