Capacity grading movement mechanism compatible with various types of polymer soft package lithium batteries

A technology of soft-packed lithium batteries and moving mechanisms, which is applied to the parts of electrical measuring instruments, measuring electricity, and measuring electrical variables, etc., can solve problems such as low work efficiency, heavy workload, and differences in capacity structure, and achieve simple structure , the effect of great applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

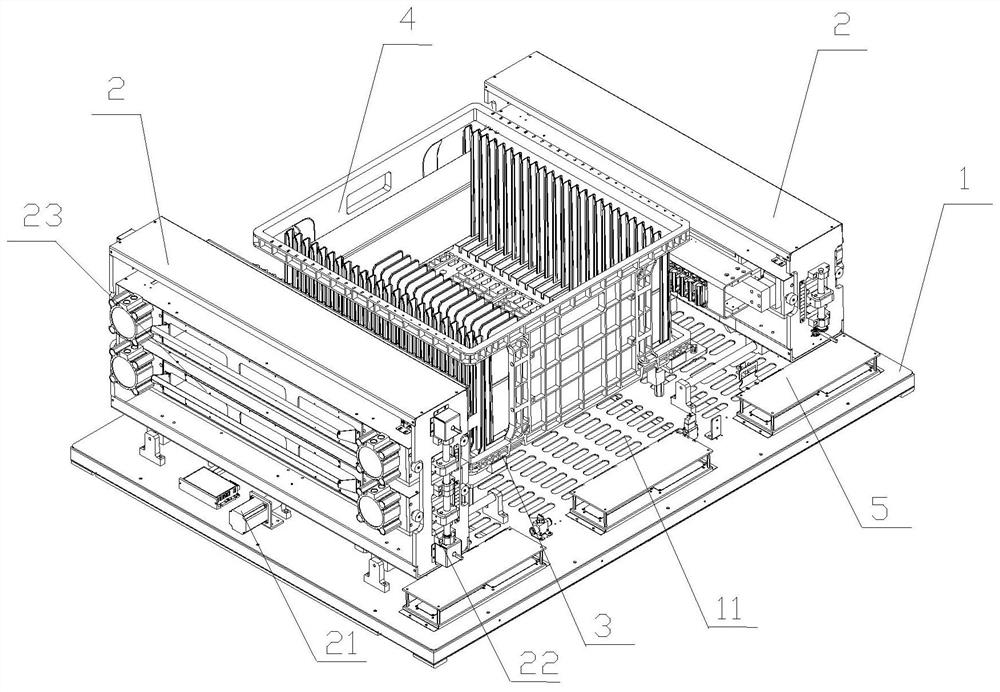

[0047] Embodiment 1 A capacity dividing motion mechanism compatible with various types of polymer soft-pack lithium batteries according to the present invention includes:

[0048] The mechanism base plate 1 has an installation reference plane, which is used to support and install the components of the divided movement mechanism;

[0049] Two sets of probe position adjustment and clamping devices 2 are symmetrically arranged on the left and right sides of the mechanism base plate, each set of probe position adjustment and clamping devices includes a position adjustment part and a pole lug clamping part, and the position adjustment part is used to adjust the pole The position of the lug clamping part; the lug clamping part is arranged at the movable end of the position adjustment part, and the probes of the two sets of the lug clamping part are kept facing each other, which is used to clamp the polar lugs of the polymer soft-pack lithium battery ;

[0050] The battery tray supp...

Embodiment 2

[0063] Example 2 The present invention is compatible with various types of soft-packed lithium battery capacity dividing motion mechanism, which consists of five parts: mechanism base plate, probe position adjustment and clamping device, battery tray support device, battery tray, and electrical component installation block. consists of:

[0064] The bottom plate of the mechanism is the basic basic component of the entire movement mechanism that is compatible with various types of soft-pack lithium batteries;

[0065] The probe position adjustment and clamping device is located on the left and right sides of the center line of the bottom plate of the mechanism. It is used to adjust the left and right positions and the upper and lower positions of the probe, and finally achieves matching with the soft-pack lithium battery tabs, and is suitable for the soft-pack lithium battery tabs. to clamp;

[0066] The battery tray support device is located on the left and right sides of the...

Embodiment 3

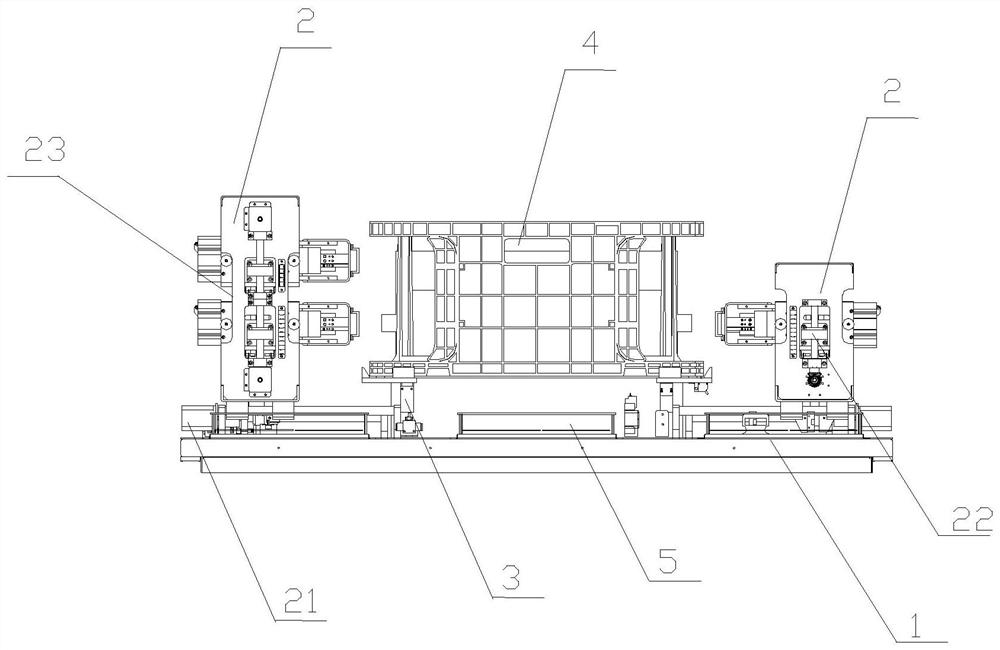

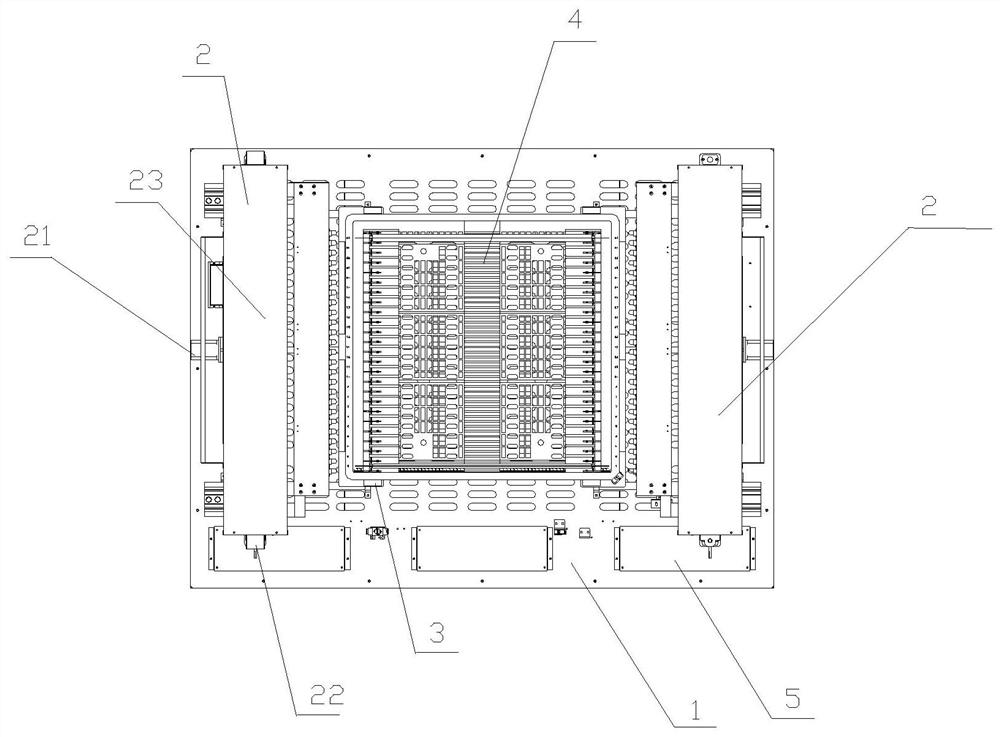

[0076]Embodiment 3 The difference between this embodiment and Embodiment 2 is that: Figure 1-3 It can be seen that the capacity-distributing motion mechanism of the present invention, which is compatible with various types of soft-pack lithium batteries, is composed of a mechanism base plate 1, a probe position adjustment and clamping device 2, a battery tray support device 3, a battery tray 4, and electrical components installed. Block 5 and other five components.

[0077] from Figure 4 It can be seen that the probe position adjustment and clamping device 2 includes two sets of horizontal moving mechanisms 21 , three sets of vertical moving mechanisms 22 and three sets of probe clamping devices 23 . The probe tab adjustment and clamping device is divided into probe position adjustment and clamping device A and probe position adjustment and clamping device B, the probe position adjustment and clamping device A and probe position adjustment and The clamping devices B are sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com