Wall punching device for building

A kind of punching equipment and construction technology, applied in stone processing equipment, work accessories, manufacturing tools, etc., can solve the problems of hole drilling deviation, reduce work efficiency, arm pain, etc., achieve precise drilling position, convenient drilling, Precisely Controlled Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

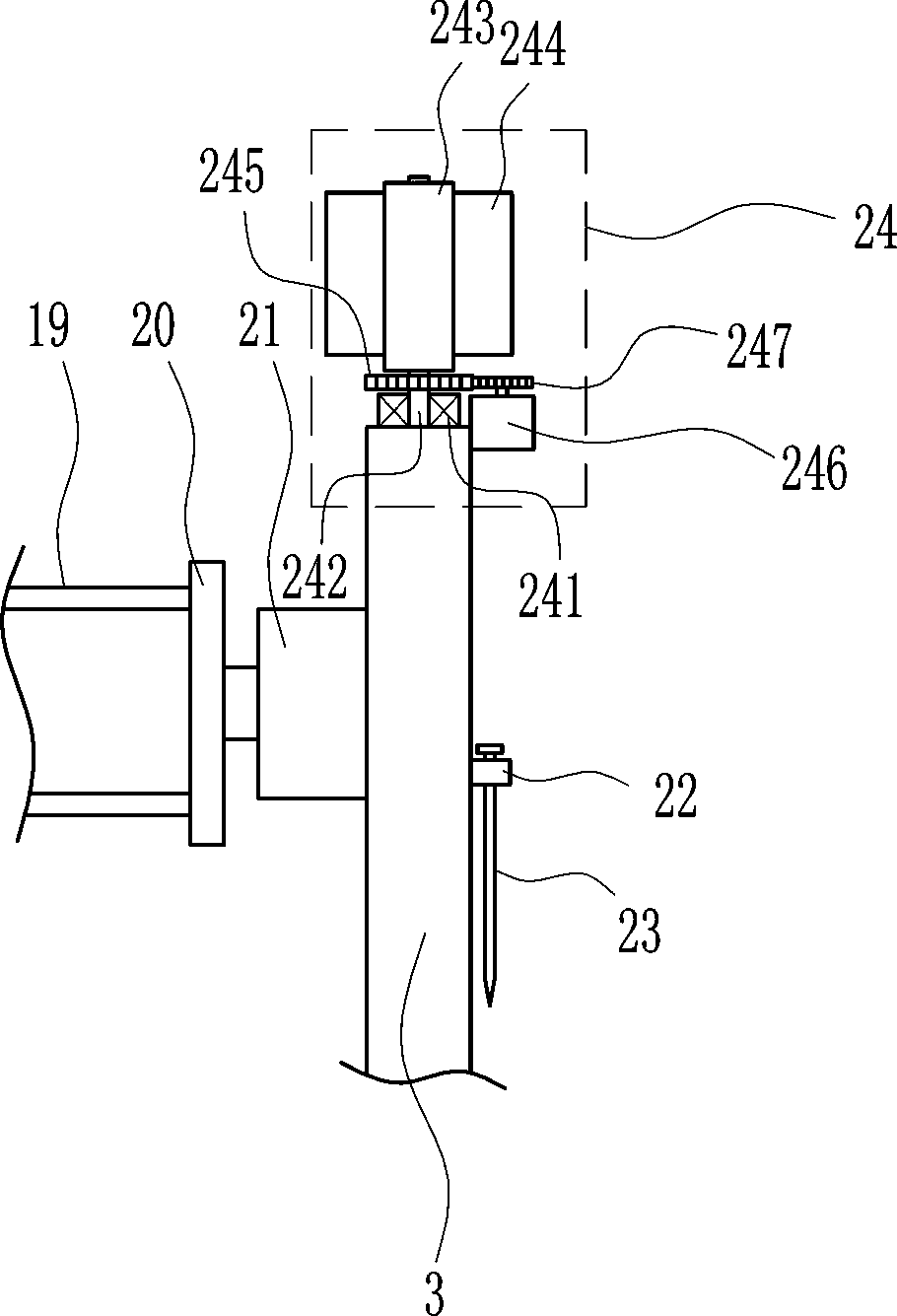

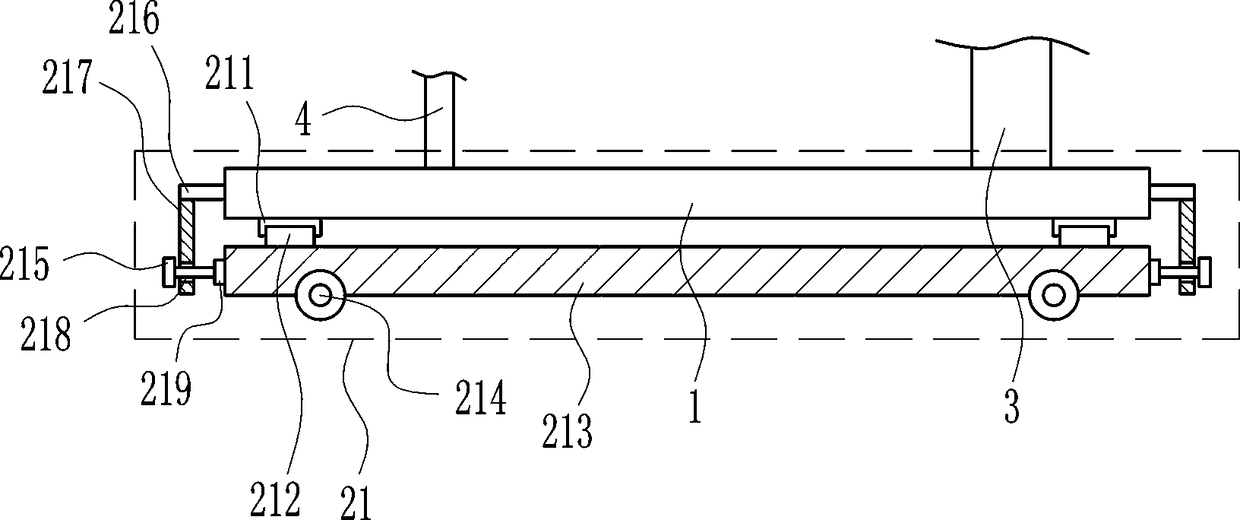

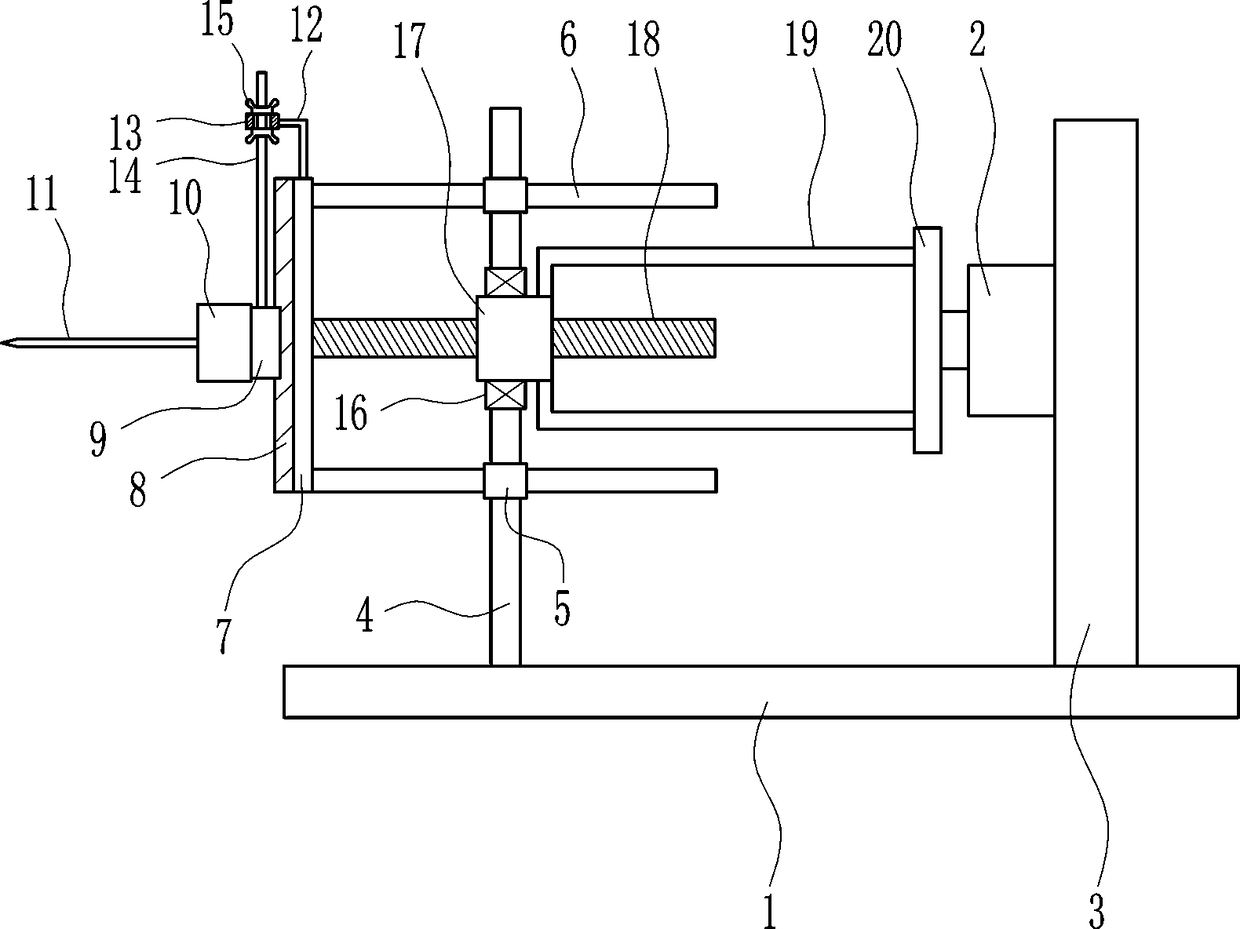

[0023] A device for punching holes in walls for construction, such as Figure 1-5 As shown, it includes a bottom plate 1, a first motor 2, a bracket 3, a mounting plate 4, a first guide sleeve 5, a guide rod 6, a first connecting plate 7, a first slide rail 8, a first slider 9, a second Motor 10, drill bit 11, L-shaped connecting rod 12, ring 13, first bolt 14, butterfly nut 15, first bearing seat 16, first nut 17, screw rod 18, L-shaped strut 19 and second connecting plate 20. There is a mounting plate 4 on the left side of the top of the bottom plate 1. The first guide sleeve 5 is provided on the upper and lower parts of the mounting plate 4. The guide rod 6 is slidably connected to the first guide sleeve 5, and the left end of the guide rod 6 is connected to the second guide sleeve. A connection plate 7, the first slide rail 8 is embedded in the middle part of the left side of the first connection plate 7, the first slide block 9 is slidably connected to the first slide rai...

Embodiment 2

[0025] A device for punching holes in walls for construction, such as Figure 1-5 As shown, it includes a bottom plate 1, a first motor 2, a bracket 3, a mounting plate 4, a first guide sleeve 5, a guide rod 6, a first connecting plate 7, a first slide rail 8, a first slider 9, a second Motor 10, drill bit 11, L-shaped connecting rod 12, ring 13, first bolt 14, butterfly nut 15, first bearing seat 16, first nut 17, screw rod 18, L-shaped strut 19 and second connecting plate 20. There is a mounting plate 4 on the left side of the top of the bottom plate 1. The first guide sleeve 5 is provided on the upper and lower parts of the mounting plate 4. The guide rod 6 is slidably connected to the first guide sleeve 5, and the left end of the guide rod 6 is connected to the second guide sleeve. A connection plate 7, the first slide rail 8 is embedded in the middle part of the left side of the first connection plate 7, the first slide block 9 is slidably connected to the first slide rai...

Embodiment 3

[0028] A device for punching holes in walls for construction, such as Figure 1-5 As shown, it includes a bottom plate 1, a first motor 2, a bracket 3, a mounting plate 4, a first guide sleeve 5, a guide rod 6, a first connecting plate 7, a first slide rail 8, a first slider 9, a second Motor 10, drill bit 11, L-shaped connecting rod 12, ring 13, first bolt 14, butterfly nut 15, first bearing seat 16, first nut 17, screw rod 18, L-shaped strut 19 and second connecting plate 20. There is a mounting plate 4 on the left side of the top of the bottom plate 1. The first guide sleeve 5 is provided on the upper and lower parts of the mounting plate 4. The guide rod 6 is slidably connected to the first guide sleeve 5, and the left end of the guide rod 6 is connected to the second guide sleeve. A connection plate 7, the first slide rail 8 is embedded in the middle part of the left side of the first connection plate 7, the first slide block 9 is slidably connected to the first slide rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com