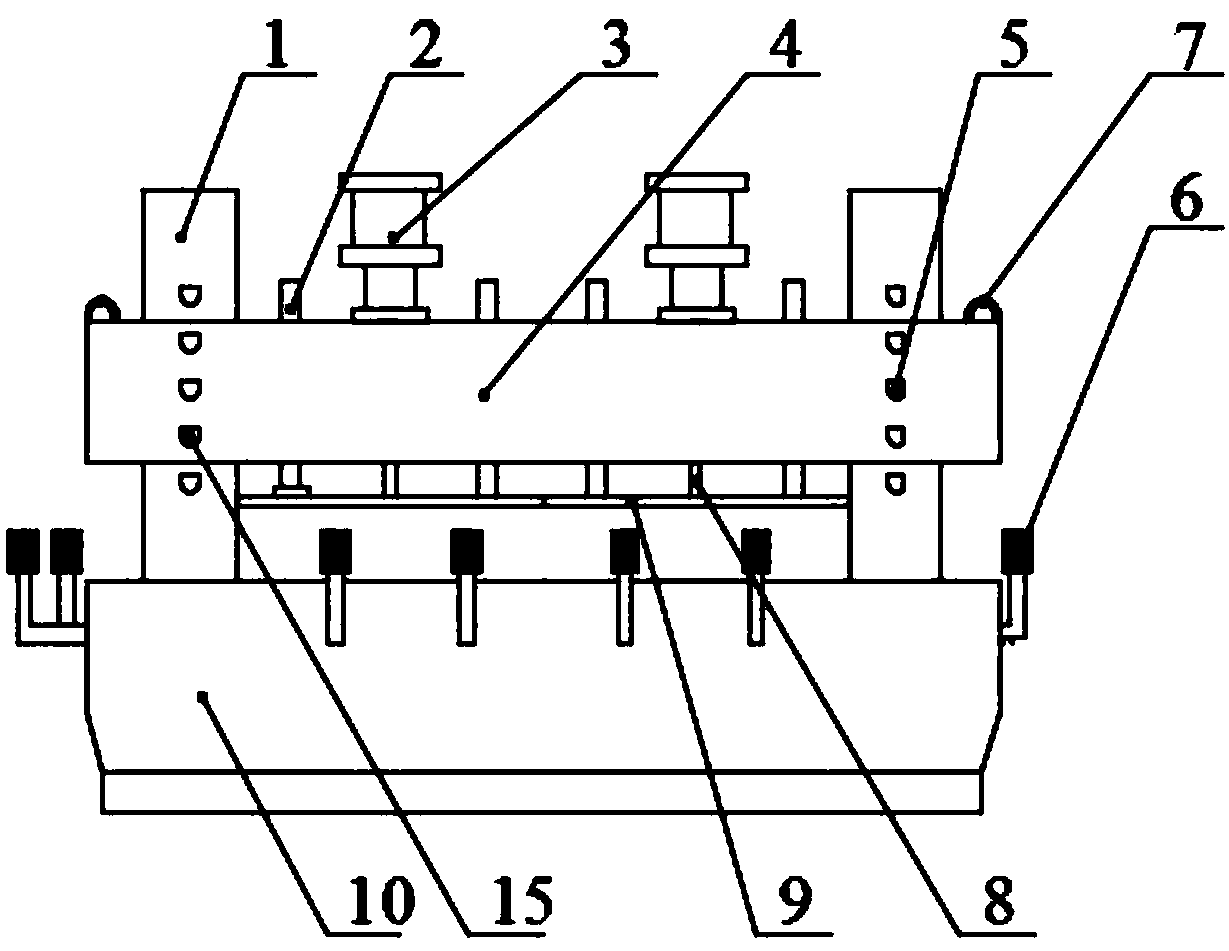

Board gluing press adjustable punching device

A stamping device and pressing machine technology, applied in veneer presses, plywood presses, wood processing equipment, etc., can solve the problems of adjusting the working mode of stamping devices, reducing enterprise production efficiency, increasing processing costs, etc., to ensure convenience Sexuality, saving energy consumption, and ensuring the effect of levelness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

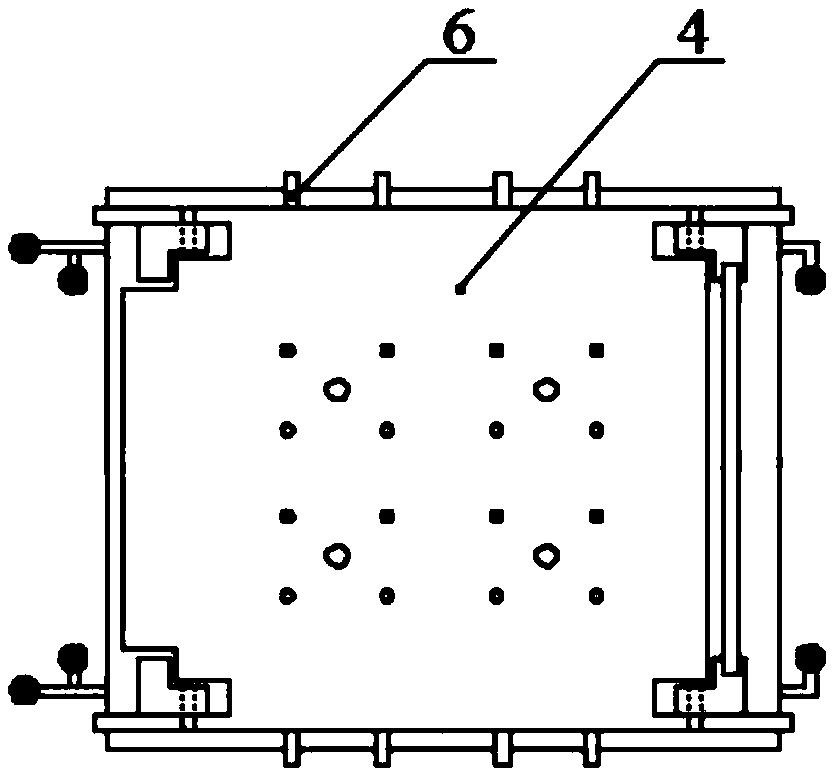

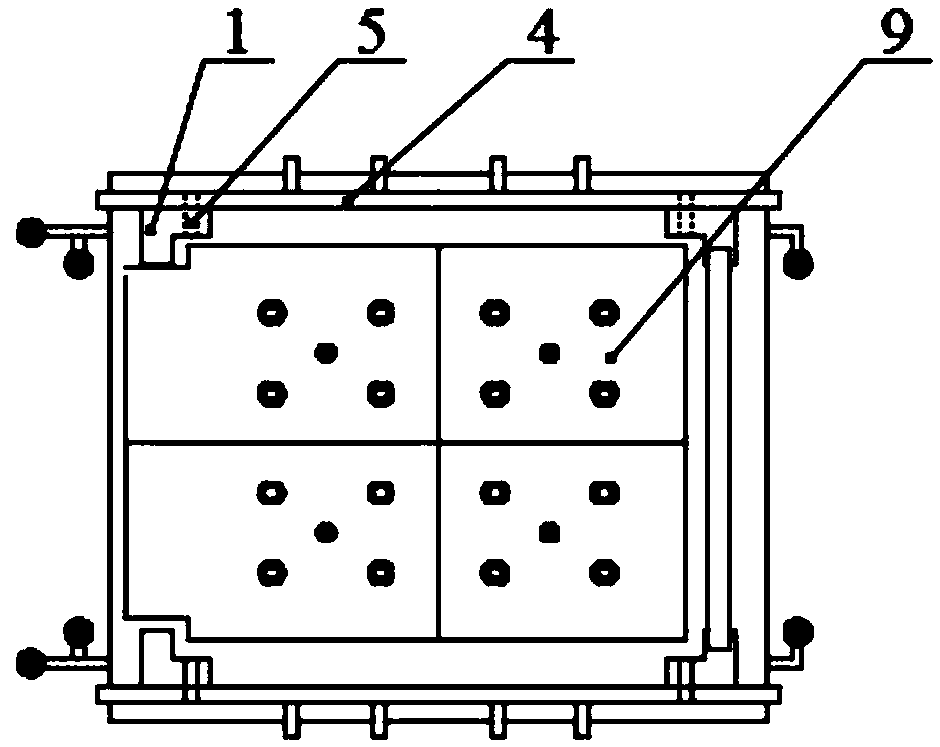

[0029] When the mold plate is debugged and installed, the mold plate is placed on the work table horizontally, the punching cylinder is ventilated, and the end of the punching cylinder piston rod is inserted into the fixed pin socket and fixed with the fixed pin. The coaxial limit rod can be manually controlled to be inserted into the fixed Pin inside the socket and fix it.

[0030] When feeding, the 6 feeding rollers push the wood board to the pre-stamping position in the workpiece table by the feeding roller and the workpiece transfer limit device.

[0031] When stamping, the length of the plate is controlled in groups. For example, for large plates, multiple sets of punching devices can be controlled at the same time, and for small plates, two sets of punching devices on the feed or discharge side can be controlled to punch at the same time.

[0032] When discharging, the punching cylinder deflates, the punching die plate rises, and finally the feeding roller provides power to dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com