Toggle rod-type servo pressing machine

A servo press, toggle technology, applied in the direction of presses, punching machines, manufacturing tools, etc., can solve the problems of high manufacturing cost, small batches, hindering the level of stamping technology, etc., to achieve simple and compact structure, low cost, high pressure The effect of diverse working curves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

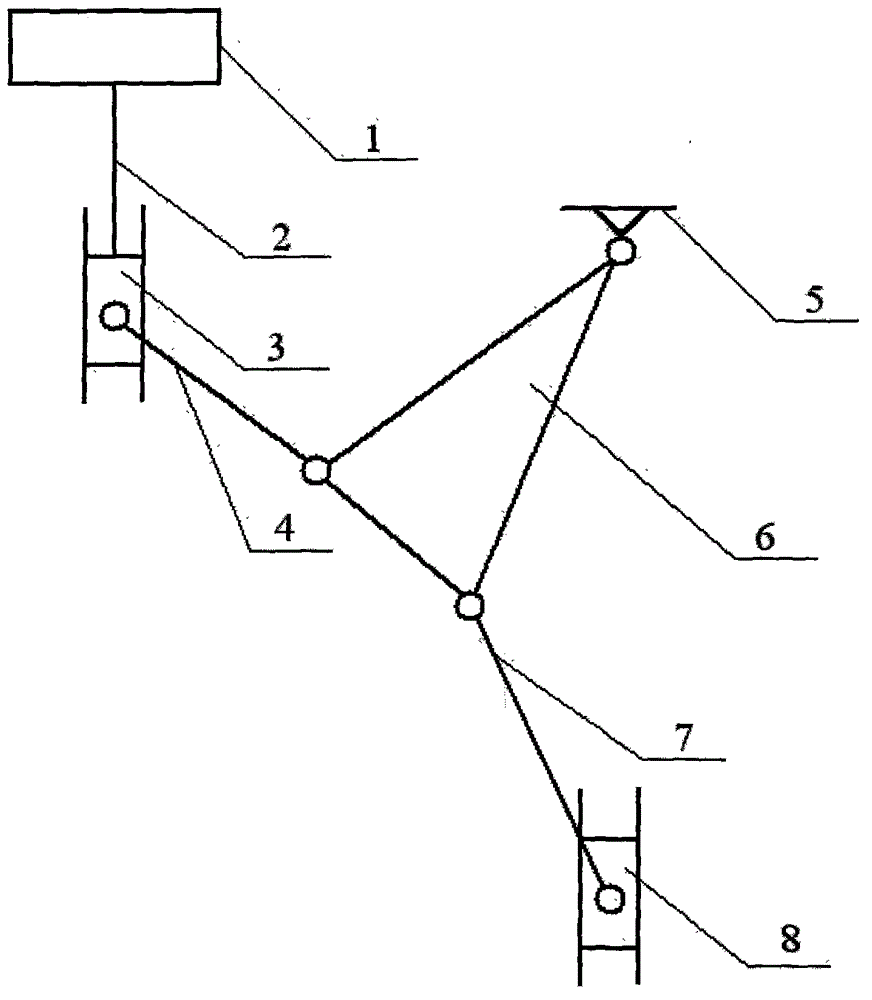

[0007] Such as figure 1 The specific embodiment of the present invention shown is a toggle-type servo press, and the press includes a servo motor 1, a ball screw 2, a slider 3, a connecting rod 4, three pairs of swing rods 6, and a frame 5. The hammer connecting rod 7 and the hammer 8, the servo motor 1 and the slider 3 are connected through the ball screw pair 2, one end of the connecting rod 4 is connected with the slider 3 through a rotating pair, and the three pairs The three nodes of the pendulum 6 are respectively connected with the connecting rod 4, the rack 5, and the hammer connecting rod 7 through the rotating pair, and the end of the hammer connecting rod 7 is connected with the punch 8 through the rotating pair, and the punch 8 is in a fixed position. within the rails.

[0008] When working, the ball screw pair 2 is used to convert the rotational motion of the servo motor 1 into a linear motion, thereby driving the slider 3 to move in the vertical direction, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com