Stamping apparatus with feed device

A technology for equipment and stamping tools, which is applied in the field of stamping equipment with a supply device to achieve the effects of reducing the number of lateral positioning, increasing the output of parts, and saving tool costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

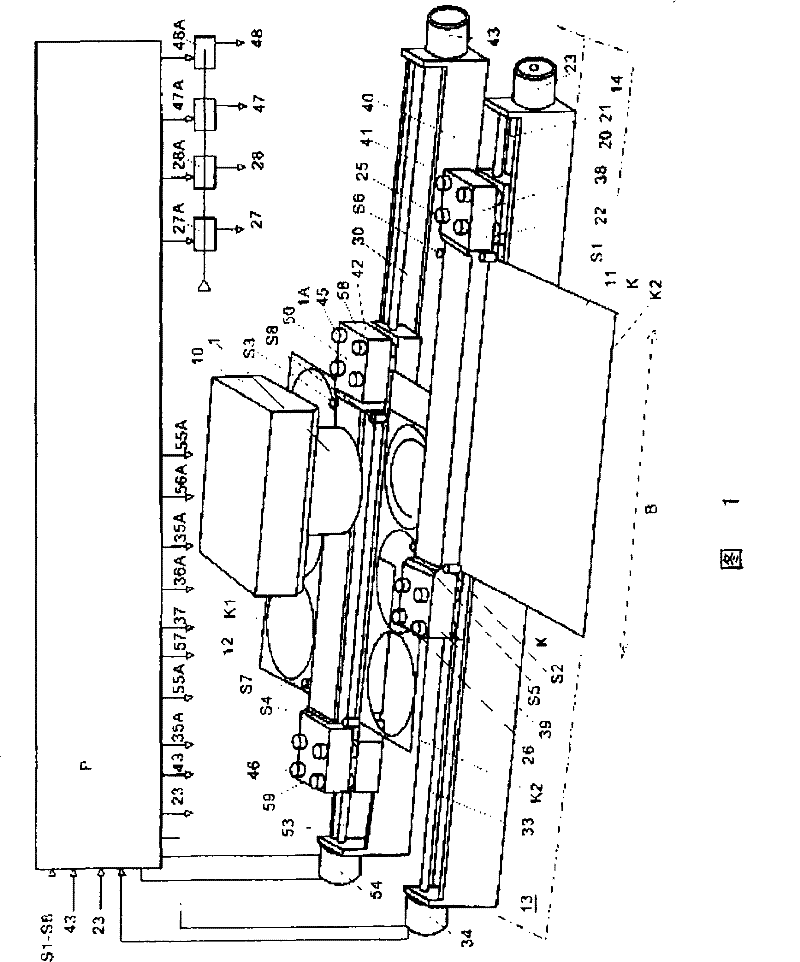

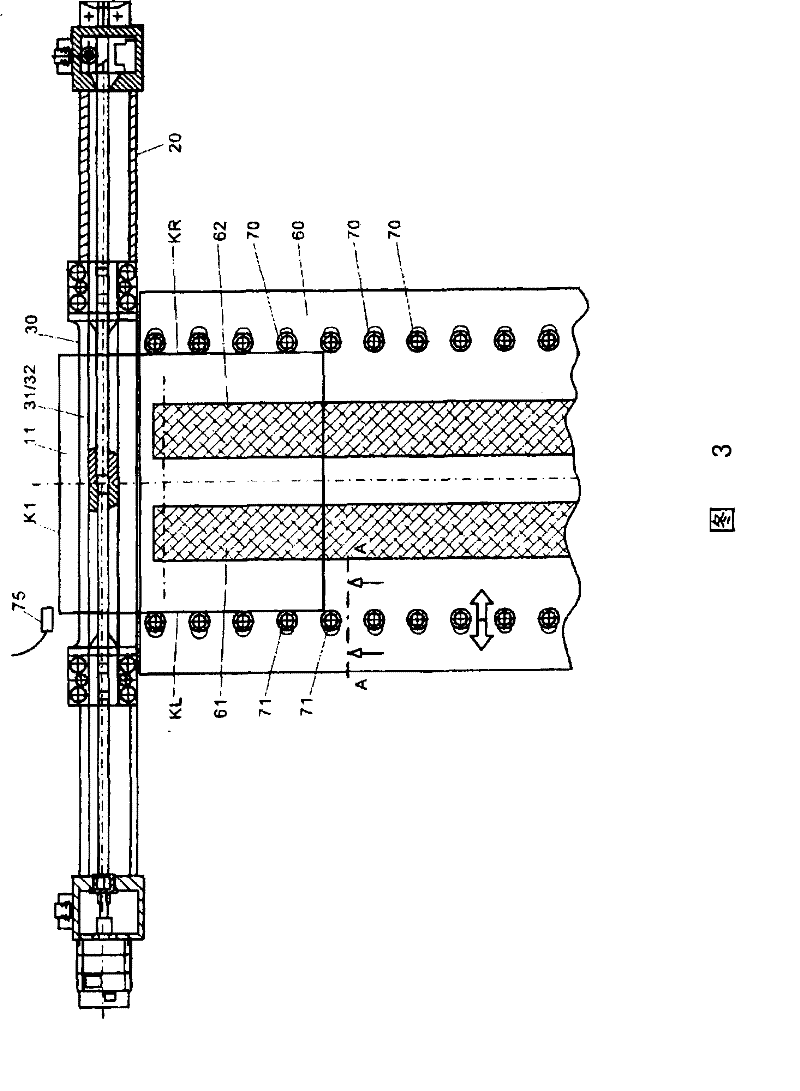

[0027] figure 1 The brackets 13 , 14 on both sides are schematically shown, on which two transverse conveyors 20 , 40 are mounted, including their positioning drive motors 23 , 43 and roller drive motors 34 , 54 . Between the supports 13 , 14 extends a schematically shown bridge 10 , on which the extrusion and stamping tool 1 is mounted, and coaxially therewith a die 1A is arranged underneath in the support. The two transverse conveyors 20 , 40 are each formed by a slide guide 21 , 41 which extend over at least the two largest sheet metal widths B .

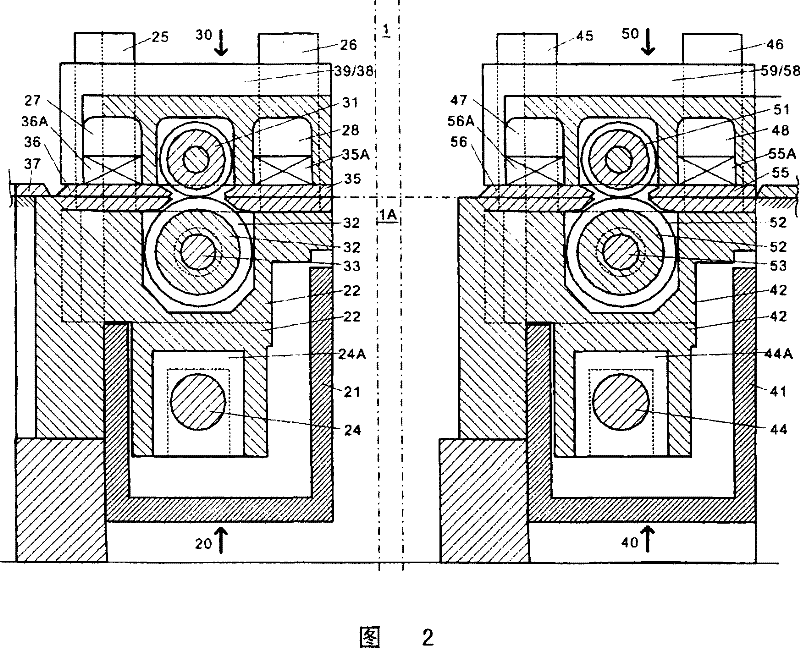

[0028] In the slide guides 21, 41, a slide 22, 42 is respectively laterally displaceably supported, which is connected to a linear drive, such as a screw drive, whose drive motor 23, 43 drives a The invisible threaded spindle extends longitudinally in the slide guide and through the slides 22, 42, in which a threaded spindle nut is mounted.

[0029] Two drive rollers are mounted one above the other in each slide 22 , 42 , wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com