Three-dimensional relief processing method of toilet lid

A technology of three-dimensional relief and processing method, applied in the field of sanitary equipment, can solve the problems of inability to achieve three-dimensional effect, and the use time of stickers is not long.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

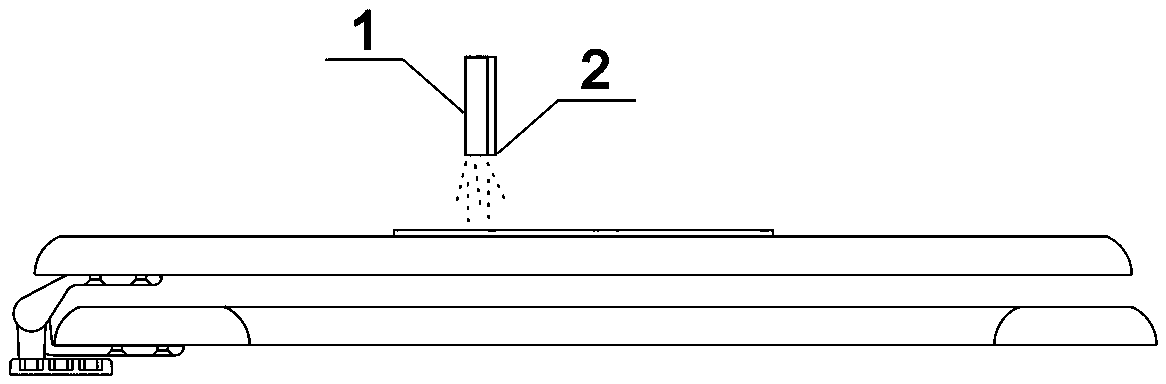

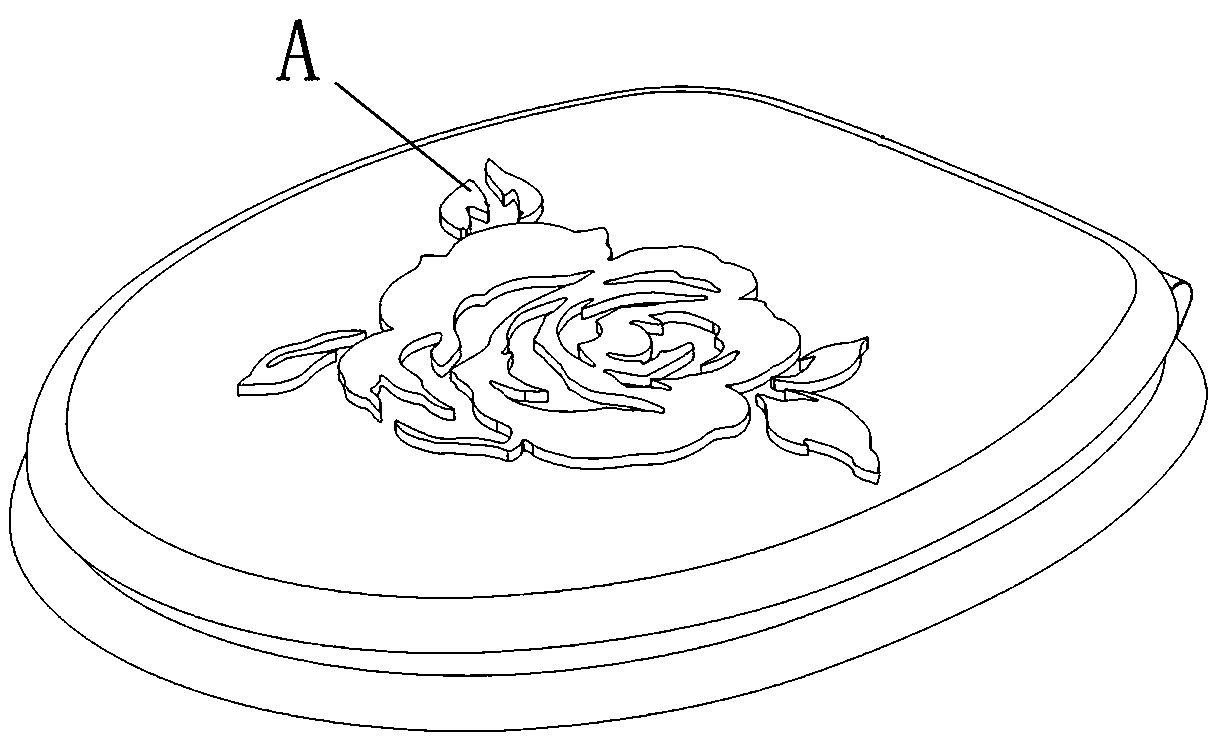

[0027] A three-dimensional relief processing method for a toilet seat, comprising the following steps:

[0028] Step 1, trim the upper cover substrate: first clean the surface of the upper cover substrate to ensure the cleanliness of the upper cover substrate surface, and then use an edger to remove the burrs on the surface of the upper cover substrate to obtain a clean surface Cover the substrate to ensure that there are no particles and excessive dust on the surface of the upper cover substrate.

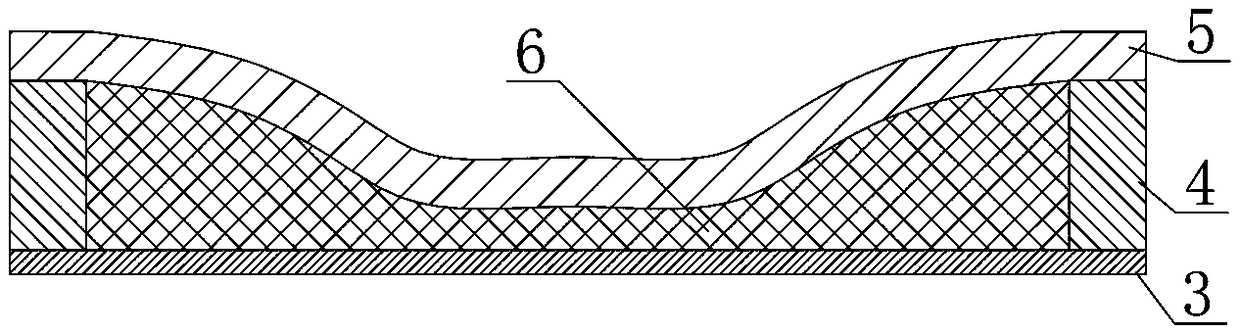

[0029] In this embodiment, when the surface of the upper cover substrate is smooth, for example, when the upper cover substrate is made of glass, plastic, urea-formaldehyde cover, stone, acrylic, PVC plate, etc., the layer stabilization layer 3 is coated on the surface of the upper cover substrate. The layer stabilizing layer 3 is a film or a sheet, and the layer stabilizing layer 3 adopts a layer stabilizer. Preferably, the layer stabilizer includes, but is not limited to, transp...

Embodiment 2

[0053] A three-dimensional relief processing method for a toilet seat, comprising the following steps:

[0054] Step 1, trim the upper cover substrate: first clean the surface of the upper cover substrate to ensure the cleanliness of the upper cover substrate surface, and then use an edger to remove the burrs on the surface of the upper cover substrate to obtain a clean surface Cover the substrate to ensure that there are no particles and excessive dust on the surface of the upper cover substrate.

[0055] In this embodiment, when the surface of the upper cover substrate is relatively rough, for example, when the material of the upper cover substrate is wood or bamboo, the stabilizing layer 3 is omitted.

[0056] Step 2: Determine the theoretical path of the embossed relief and the color system that needs to be displayed on the screen: the theoretical path of the embossed embossed is the lines or patterns that outline the three-dimensional relief image.

[0057] The method fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com